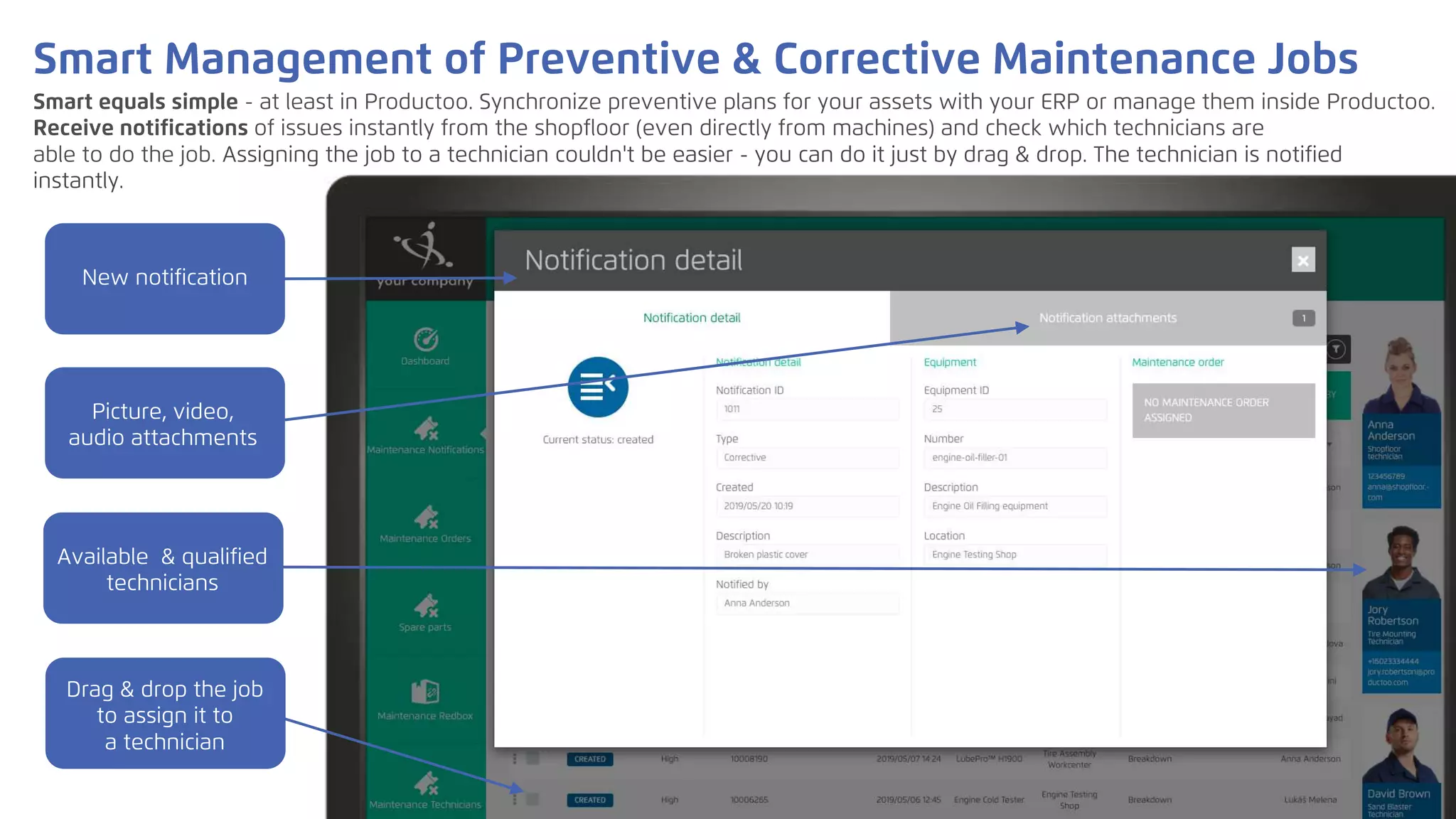

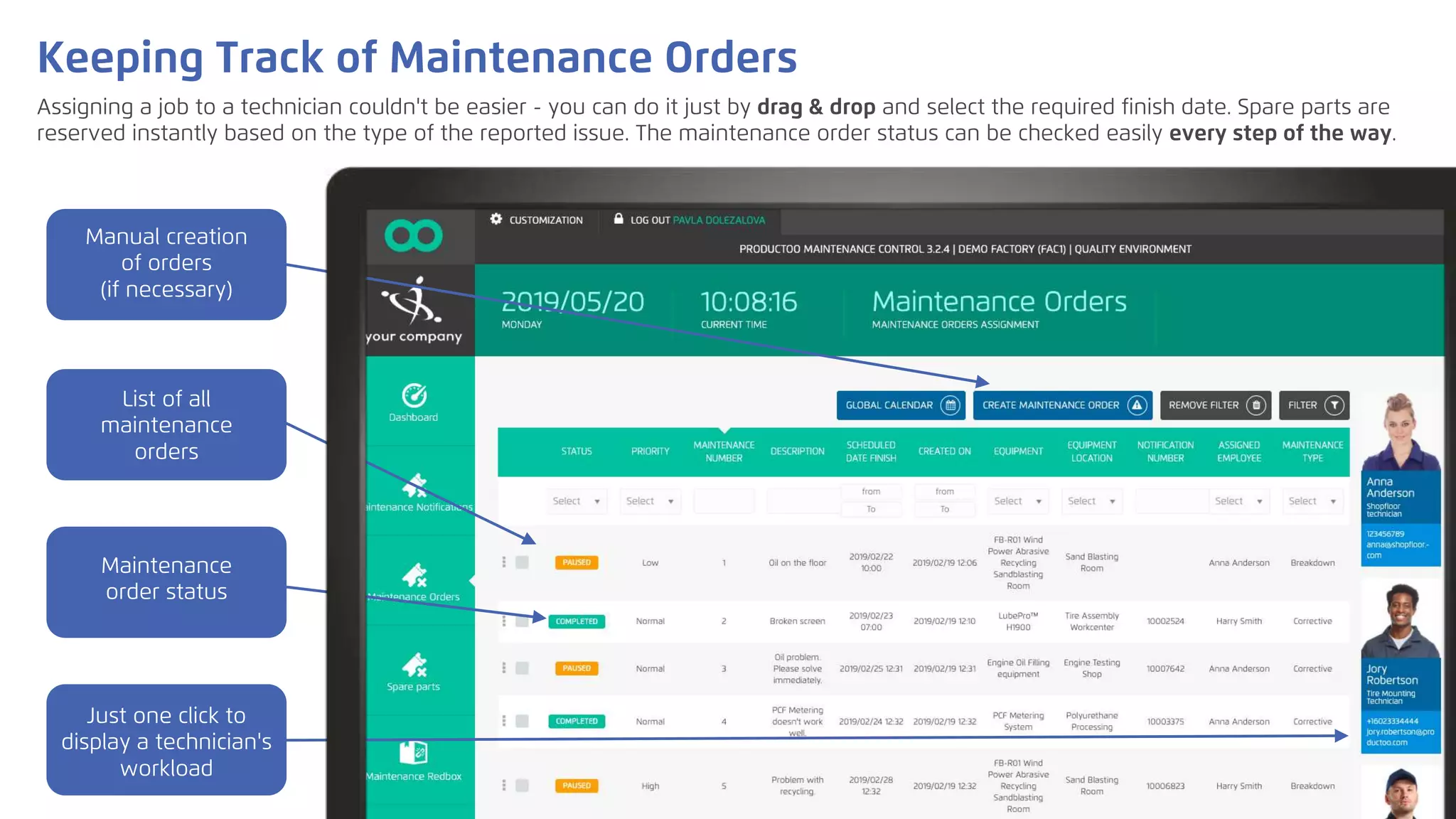

The document discusses a maintenance control smart factory suite aimed at improving preventive maintenance and reducing downtime costs for manufacturers. Key features include instant issue reporting, easy technician job assignments via drag & drop, and seamless ERP integration for efficient data management. The solution offers mobile accessibility for technicians and ensures complete traceability and data availability, enhancing overall maintenance execution.