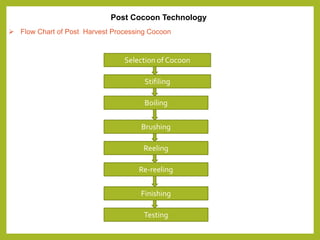

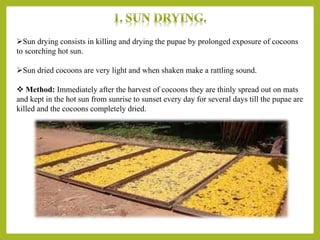

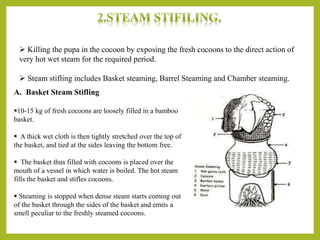

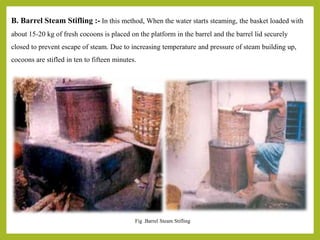

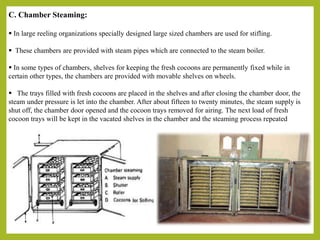

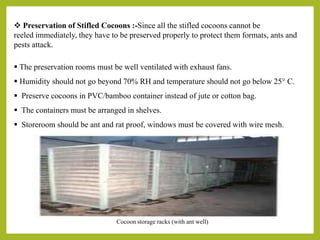

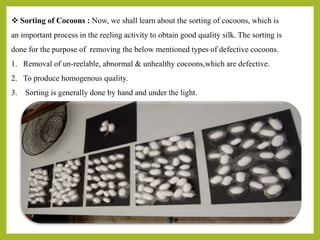

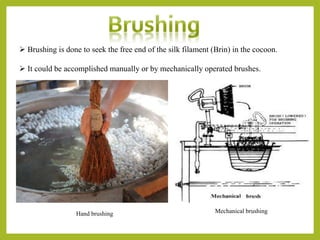

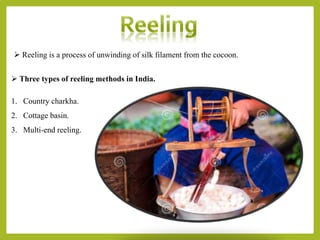

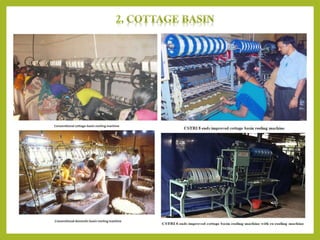

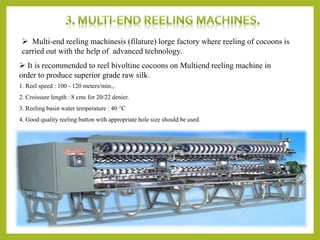

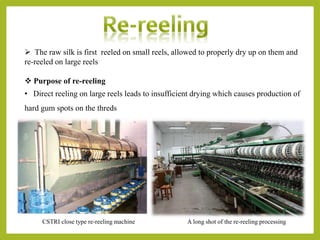

The document discusses the post-cocoon processing of different types of silkworm cocoons. It covers steps like sorting, stifling through sun drying or steam, preservation of cocoons, boiling, brushing to find the silk filament, reeling through various methods like charkha or multi-end machines, re-reeling onto larger reels, and finishing to remove defects and produce high quality raw silk skeins and bales. Different techniques are used depending on the type and scale of production.