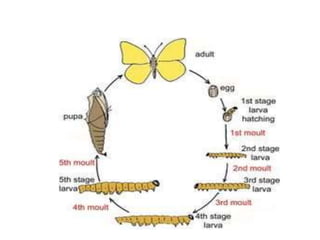

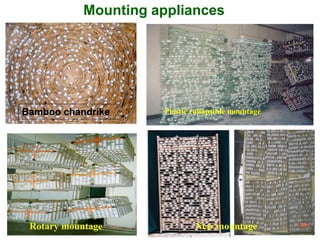

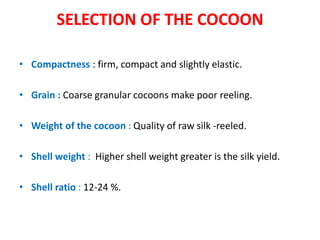

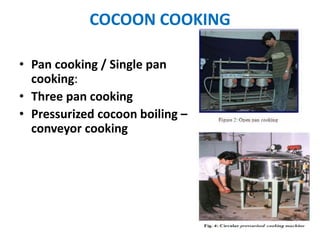

This document provides an overview of the process of cocoon harvesting and processing for silk production. It discusses the stages of late age worm rearing and cocoon harvesting. It then details the various steps involved in cocoon processing including selection, stifling/drying, sorting, cooking, brushing, reeling, croisure, rereeling, winding, rewinding, doubling, twisting, degumming, bleaching, dyeing, lacing, skeining and book making. The goal is to transform harvested cocoons into raw silk thread through these processing steps.