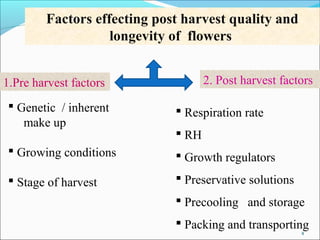

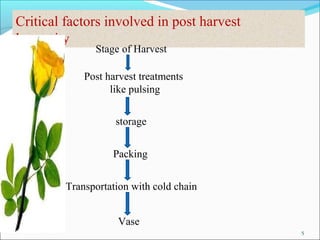

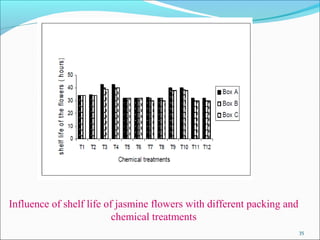

The document discusses the importance of post-harvest handling of flowers to maintain their quality and longevity, highlighting factors such as the stage of harvest, pre-cooling, pulsing treatments, and the use of preservative solutions. It emphasizes the need for optimal packaging and cold chain management during transportation to enhance shelf life. Additionally, it explores grading techniques and recent advancements in packaging materials and technologies for the export of flowers.