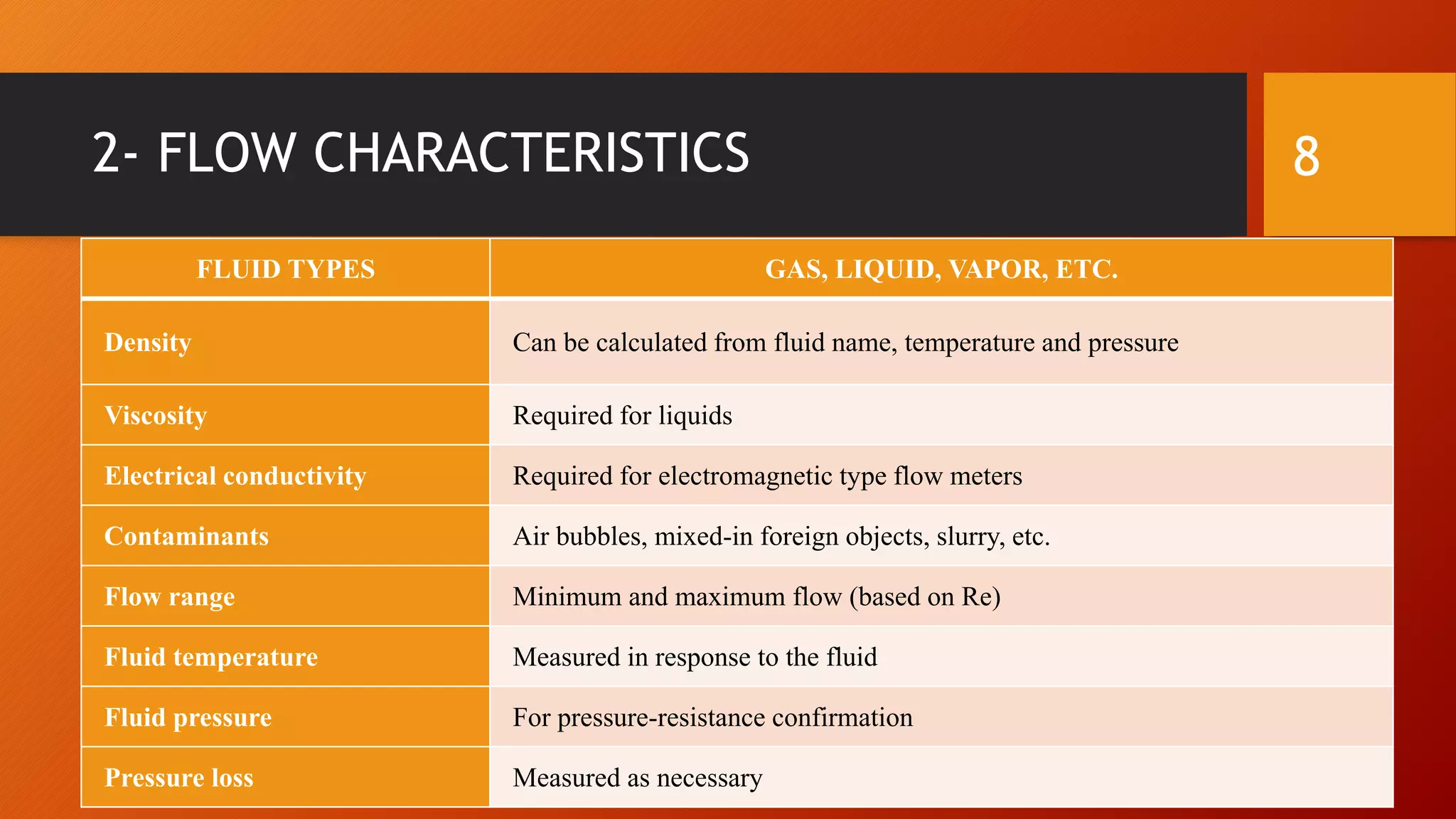

This document discusses two methodologies for selecting flowmeters: traditional selection and best-in-class methodology. The traditional method involves selecting based on past practices or purchase price without considering all relevant factors. The best-in-class methodology is a 6-step process that evaluates: 1) the measurement purpose, 2) flow characteristics, 3) flowmeter capabilities, 4) external parameters, 5) economic factors, and 6) a product selection matrix to ensure the best instrument match for the application. Following these criteria helps focus on key factors and prioritize selections for a more effective flowmeter choice.