SECONDARY PIPE RACK AND PIG LAUNCHER.docx

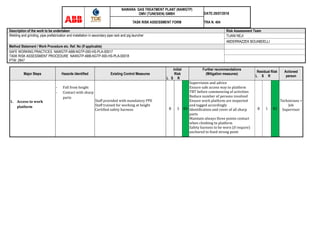

- 1. Description of the work to be undertaken Risk Assessment Team Welding and grinding, pipe prefabrication and installation in secondary pipe rack and pig launcher TIJANI NEJI ABDERRAZZEK BOUABDELLI Method Statement / Work Procedure etc. Ref. No (If applicable) SAFE WORKING PRACTICES NAWGTP-ABB-NGTP-000-HS-PLA-00017 TASK RISK ASSESSMENT PROCEDURE NAWGTP-ABB-NGTP-000-HS-PLA-00018 PTW: 2847 Major Steps Hazards Identified Existing Control Measures Initial Risk L S R Further recommendations (Mitigation measures) Residual Risk L S R Actioned person 1. Access to work platform - Fall from height - Contact with sharp parts Staff provided with mandatory PPE Staff trained for working at height Certified safety harness B 3 B3 Supervision and advice Ensure safe access way to platform TBT before commencing of activities Reduce number of persons involved Ensure work platform are inspected and tagged accordingly Identification and cover of all sharp parts Maintain always three points contact when climbing to platform Safety harness to be worn (if require) anchored to fixed strong point B 1 B1 Technicians + Job Supervisor NAWARA GAS TREATMENT PLANT (NAWGTP) OMV (TUNESIEN) GMBH DATE:28/07/2018 TRA N. 404 TASK RISK ASSESSMENT FORM

- 2. Major Steps Hazards Identified Existing Control Measures Initial Risk L S R Further recommendations (Mitigation measures) Residual Risk L S R Actioned person 2. Preparation of welding joint - Personnel injury - Fire - Electrocution - Slips/trips Staff provided with mandatory PPE Specific PPE available Trained staff Quarterly inspection of tools Fire extinguisher available C 4 C4 Supervision and advice Barrication PTW to be issue and available in work location Daily visual inspection of tolls and equipment Use only inspected and color coded tolls and equipment Ensure that safety guard protection is installed for each tools Use grinding disk according to speed rotation of grinding machine Staff to weak additional PPE (face shield, mechanical gloves, apron…) Hold tools with both hands Do not use force and do not exert excessive pressure on the tool Fire watch man stand by in work area Remove all combustible materials Protect all flammable parts by fire retardant blanket Earthing of electrical equipment’s Protect electrical cables Reduce number of person involved Housekeeping and materials arrangement Proper cable management HSE area inspection Safe distance to rotating tools parts to be maintained at all time”. C 2 C2 Technicians, Job Supervisor, HSE SPV - Noise Ear protection available B 2 B2 Involved team to wear ear protection Information all neighboring staff Reduce exposure time Reduce number of person involved B 1 B1 Technicians, Job Supervisor

- 3. Major Steps Hazards Identified Existing Control Measures Initial Risk L S R Further recommendations (Mitigation measures) Residual Risk L S R Actioned person 3. Welding activities - Personnel injury - Exposure to ultraviolet radiation - Burns - Fire - Exposure to welding fume Staff provided with mandatory PPE Specific PPE available Trained staff Quarterly inspection of tools Fire extinguisher available B 4 B4 Supervision and advice Daily visual inspection of tolls and equipment Staff to weak additional PPE (welding shield, welding gloves, apron…) Fire watch man stand by in work area Remove all combustible materials Protect all flammable parts by fire retardant blanket Protection of power cables Ventilation of welding area Reduce number of person involved Rotate persons involved Regular health surveillance HSE area inspection B 2 B2 Welders, Job Supervisor, HSE SPV 4. Cutting / fitting pipe by threading machine - Personnel injury - Electrocution - Slips/trips Staff provided with mandatory PPE Staff trained for using treading machine Quarterly inspection of equipment C 4 C4 Supervision and advice Daily visual inspection of tread machine Only qualified and trained person is authorized to use this machine Do not wear loose clothes Do not exert a force higher than capacity of tread machine Earthing of tread machine Protection of electrical cables Prohibit access to work area for unauthorized person Housekeeping and materials arrangement in work area Safety device of machine must be available and operational Reduce number of persons involved HSE area inspection safe distance to rotating tools parts to be maintained at all time”. C 2 C2 Fabricator, Job Supervisor, HSE SPV

- 4. Major Steps Hazards Identified Existing Control Measures Initial Risk L S R Further recommendations (Mitigation measures) Residual Risk L S R Actioned person 5. Rigging of pipes and accessories on trailer - Fall form height - Struck between - Personnel injuries Staff provided with mandatory PPE Staff trained for rigging B 3 B3 Supervision and advice Ensure safe access to trailer Second person to hold the ladder Install ladder only on level and stable ground Do not work close to extremities of trailer Never put hands between pipes and/or supports Daily inspection of lifting accessories Reduce number of persons involved A 1 A1 Rigger, Job Supervisor 6. Lifting of pipe and accessories - Personnel injury - Fall of load - Collision with obstacles Staff provided with mandatory PPE Qualified crane operator Certified lifting equipment’s Tag lines available C 4 C4 Supervision and advice Daily visual inspection of lifting equipment’s and accessories Barrication of lifting area Nobody enter under suspended load Safety distance to be maintained to obstacles Reduce number of persons involved Assessment of load weight before to proceed Do not exceed maximum load capacity of equipment(s) Ensure good stability of lifting equipment’s and stable ground conditions Permanent banksman communication with operator Check weather conditions Using of two taglines for guiding the load Attention when working close to electrical lines HSE area inspection B 2 B2 Operator, Job Supervisor, HSE SPV

- 5. Major Steps Hazards Identified Existing Control Measures Initial Risk L S R Further recommendations (Mitigation measures) Residual Risk L S R Actioned person 7. Manual handling of pipes and accessories - Personnel lumbago injury - Sharp material - Hands Injury Staff provided with mandatory PPE C 4 C4 Supervision and advice Awareness for correct manual handling Reduce exposure of staff, always try to avoid any manual lifting by the use of mechanical lifting equipment Take regular breaks Rotate persons involved on manual handling Apply safe manual handling techniques Assess load prior to manual handling Involve more persons when necessary Identification and cover of all sharp parts Do not put hands under load C 1 C1 Job Supervisor, Technicians 8. Working at height using man lift - Falling from the man basket - Injury - Man lift rollover - Fall of objects Staff provided with mandatory PPE Equipment TP certified Safety harness certified C 3 C3 Supervision and advice PTW mandatory Man basket daily inspection to be done Barrication of work area Ensure that all guardrail of man basket are in place Respect the load chart Respect the safe work limit Ensure that all the switch are functional Do not over load man lift Ensure stable and level ground for using man basket Wear helmet with chain strap Only trained and qualified staff can be involved No work outside the man basket is authorized Ensure safety harness attached at all time by basket anchor point Tools attachment HSE area inspection B 1 B1 Technicians, Job Supervisor, Operator, HSE SPV

- 6. Major Steps Hazards Identified Existing Control Measures Initial Risk L S R Further recommendations (Mitigation measures) Residual Risk L S R Actioned person 9. Working during the night shift - Fatigue - Animal’s hazards - Slips/trips - Poor visibility Staff provided with mandatory PPE Light torch available Walk ways lighten C 3 C3 Supervision and advice Take regular breaks Avoid to work long hours during night Reduce number of people involved Rotate person involved in night shift activities No lone working are allowed Reporting of fatigue signs Stop work and release person immediately when fatigue signs observed Transparent glasses to be wear by all involved staff Torch light to be wear by all staff Use only safe walkway Assess lighting conditions, sufficient light shall be ensured Housekeeping and materials arrangement Avoid sitting near materials storage areas Communication means to be ensured Ensure mandatory presence of ambulance and medical staff during the night activities HSE area inspection Helmet torch, clean glasses A 1 A1 Technicians, Job Supervisor HSE Supervisor Electrician Mechanical 10. Rigging and erection using man lift Rigger to attach lifting accessories to the beam lift on the ground: - Personnel injury - Slip and trip hazards Staff provided with mandatory PPE Trained and qualified rigger Valid third party inspection of the lifting accessories C 3 C3 Supervision and advice Maintaining free safe access Only authorized person to be involved Clear instruction to crane operator to not operate the crane until rigging completed Do not put hand between load and supports/cable/sling/chain Inspection of equipment’s and accessories before to start A 1 A1 Rigger, Job Supervisor, Operator

- 7. Major Steps Hazards Identified Existing Control Measures Initial Risk L S R Further recommendations (Mitigation measures) Residual Risk L S R Actioned person Rigger to remove sling using man basket: - Falling from the height - Falling objects - Personnel injury Staff provided with mandatory PPE TP certified man basket Certified safety harness C 3 C3 Supervision and advice Man basket daily inspection to be done Barrication of working area Ensure that all guardrail of man basket are in place Respect the load chart Respect the safe work limit Ensure that all the switch are functional Ensure stable and level ground for using man basket Do not overload man basket Wearing helmet with chain strap Only qualified operator can be involved No work outside of man basket is authorized Wear safety harness always connected to basket anchor point Tools attachment HSE area inspection B 1 B1 Technicians, Job Supervisor, Operator, HSE SPV 11. Work on scaffold - Fall from height - Fall of tools - Collapse of scaffold Staff provided with mandatory PPE Certified harness provided Certified scaffolding materials Trained staff for working at height and scaffold erection C 3 C3 Supervision and advice Only trained personnel for working at height can be involved Daily visual inspection of scaffold Barrication of working area Do not exceed the maximum load capacity of scaffold Use only scaffold green tagged Scaffold shall be erected by certified scaffolders Tools attachment Materials arrangement Nobody enter under working at height activities Do not drop tools and materials from platform Safety harness attached to strong anchor point to be wear when require Do not work outside of scaffolding HSE area inspection B 1 B1 Technicians, Job Supervisor, HSE SPV

- 8. Major Steps Hazards Identified Existing Control Measures Initial Risk L S R Further recommendations (Mitigation measures) Residual Risk L S R Actioned person 12. Working outside manbasket Working on Midrail of the manbasket - Fall from height - Falling objects - Injury PTW to be available Staff wear mandatory PPE Only qualified and trained person for working at height Safety harness with double lanyard and fall arrestor (more than 6m) Reduce working time outside of manbasket 100% hook up of harness 100% of the time Superposed work is prohibit C 3 C3 Barrier off under the working area Prohibit person access under the working area Effective and close supervision Wear safety helmet with chain strap Tools to be attached or use tools belt Do not operate man lift close to working persons During the work basket shall be parked in the close position near the erector Jumping on the steel structure is prohibited HSE area inspection Reduce number of people involved B 1 B1 Job Supervisor Technicians Operator HSE SPV 13. Working at height using manlift - Falling from the man basket - Injury Mandatory PTW Wear adequate PPE Wearing helmet with chin strap Only trained and qualified staff can be involved No work outside the man basket is authorized Use only certified man basket Wearing certified harness with double lanyard always connected C 3 C3 Supervision and advice Man basket daily inspection to be done. Barrication of area Ensure that all guardrail of man basket are in place Respect the load chart Respect the safe work limit Ensure that all the switch are functional B 1 B1 SUPERVISOR WORKER + OPERATOR

- 9. Major Steps Hazards Identified Existing Control Measures Initial Risk L S R Further recommendations (Mitigation measures) Residual Risk L S R Actioned person 14. Arrangement of pipes and boxes by using Telescopic/ forklift - Personnel injury - Equipment rollover Staff provided with mandatory PPE Qualified equipment operator TP certified equipment’s C 4 C4 Supervision and advice Barrication of work area Assess ground condition, ensure stable and level ground Banksmen to escort equipment’s Daily visual inspection of equipment’s Ensure adequate load store position Telescopic/forklift do not lift more than 6 meter length pipe Lashing of load by equipment forks (if unstable) Reduce number of persons involved Maintain safe distance to operated equipment HSE area inspection B 2 B2 Operator, Banksman Job Supervisor, HSE SPV Note: L Likelihood A – E (as per HSE Risk Assessment Matrix)S Severity 1 – 5 (as per HSE Risk Assessment Matrix)R Risk = L S Very Low - Low - Medium - High (as per HSE Risk Assessment Matrix) Approved by ___ _____ For additional information please refer to document NAWGTP-ABB-NGTP-000-HS-PLA-00018 - Task Risk Assessment Procedure Signature ____________________