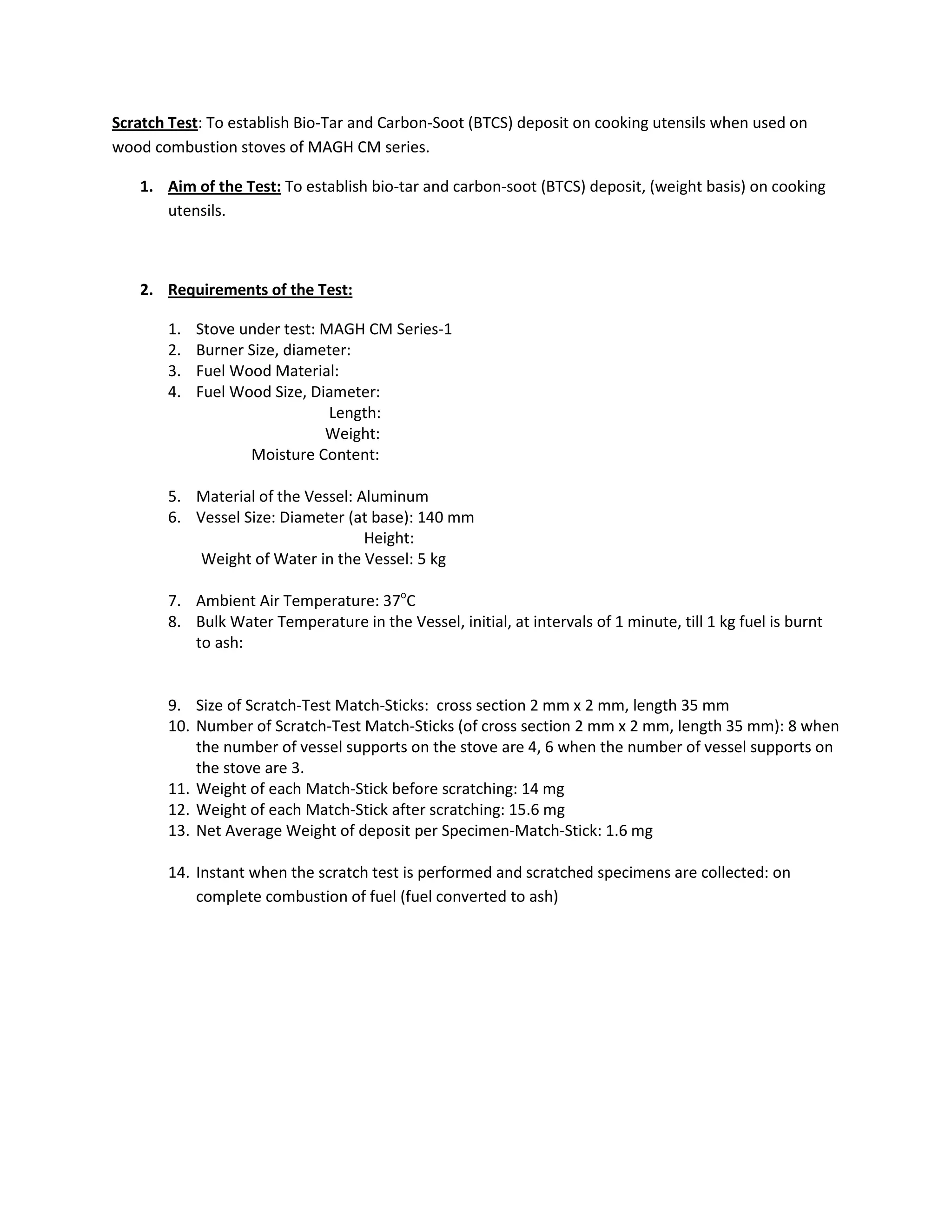

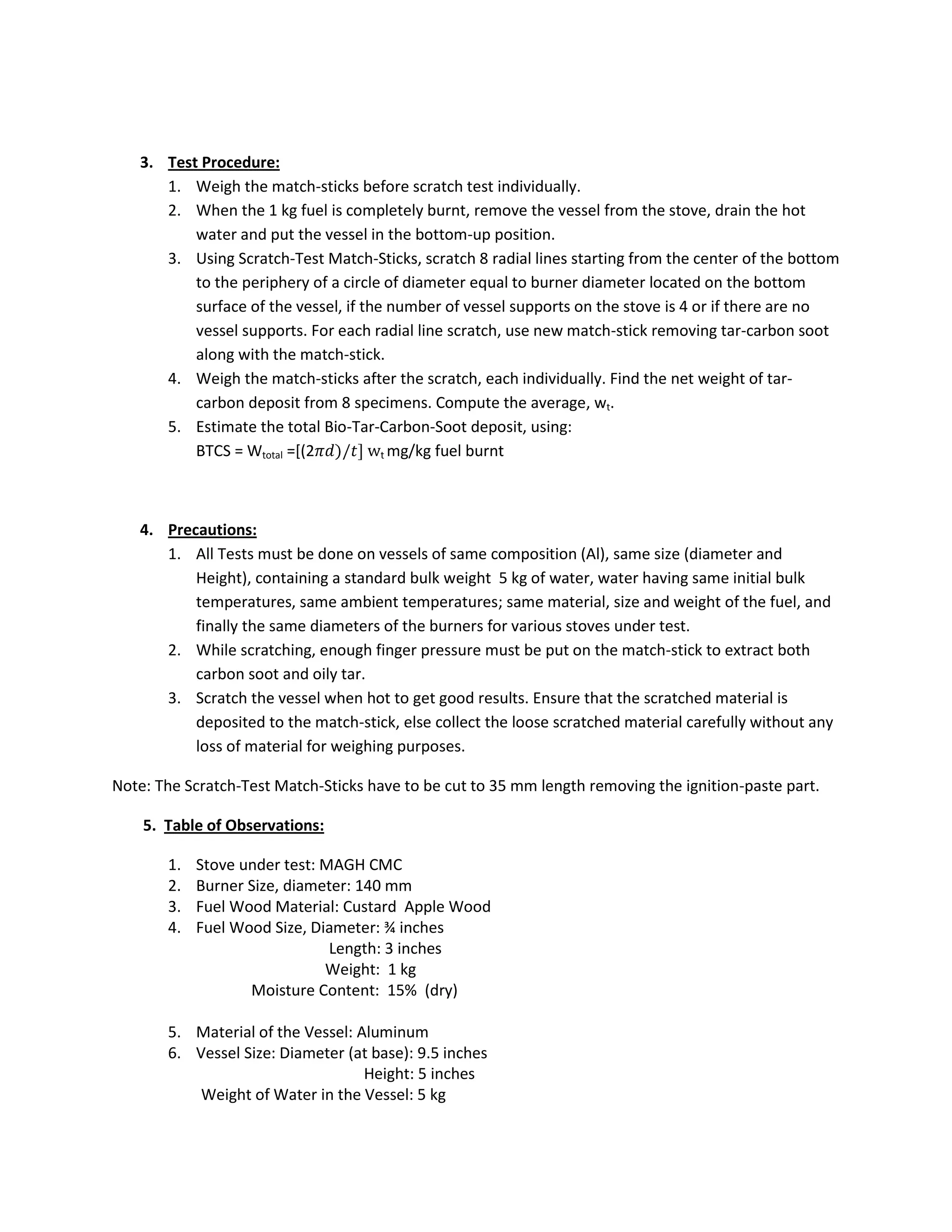

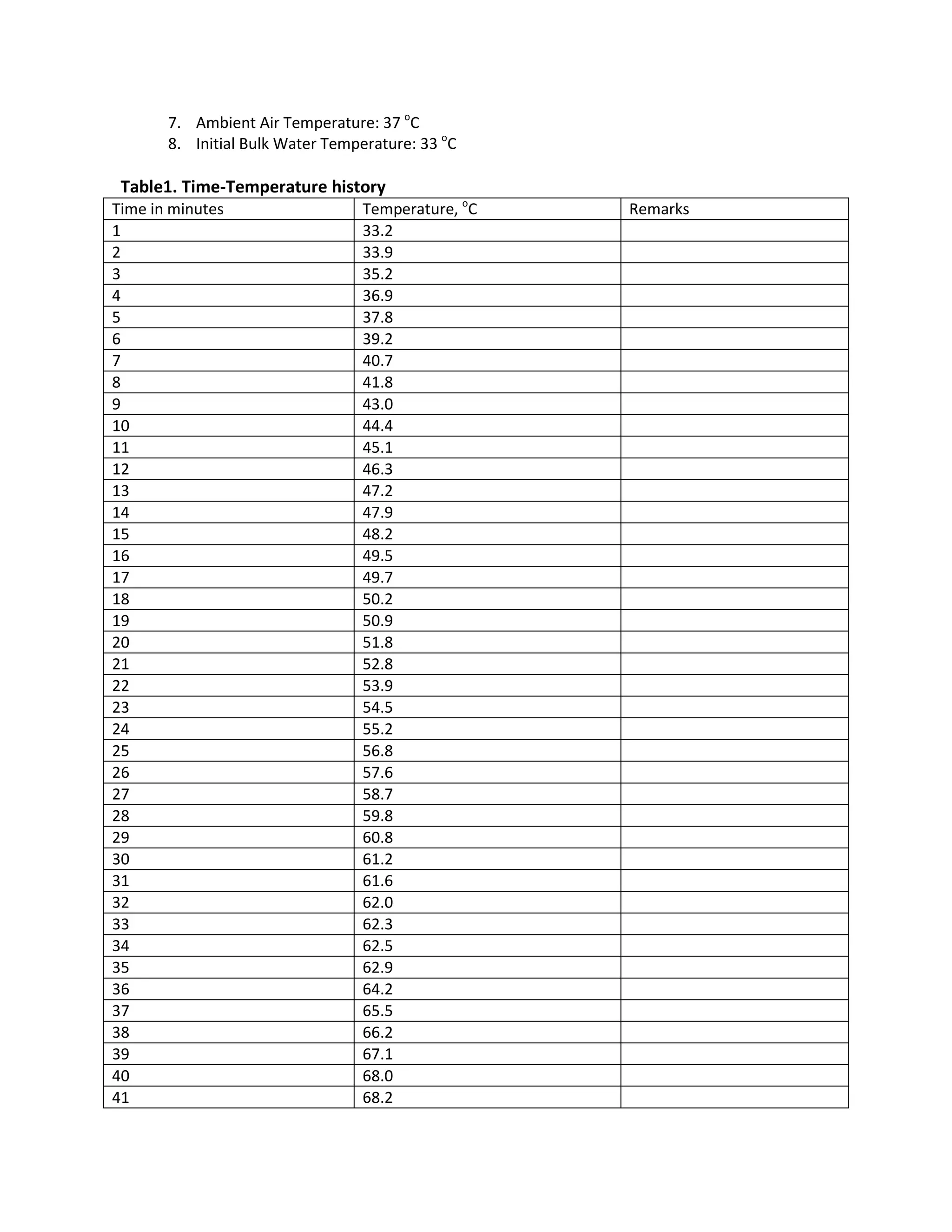

1. The document describes a scratch test conducted to measure bio-tar and carbon-soot (BTCS) deposits on cooking utensils when used on a MAGH CM series wood combustion stove.

2. The test involved using matchsticks to scratch radial lines on the bottom of an aluminum vessel after burning 1kg of wood fuel. The weight gain of the matchsticks provided the BTCS deposit measurement.

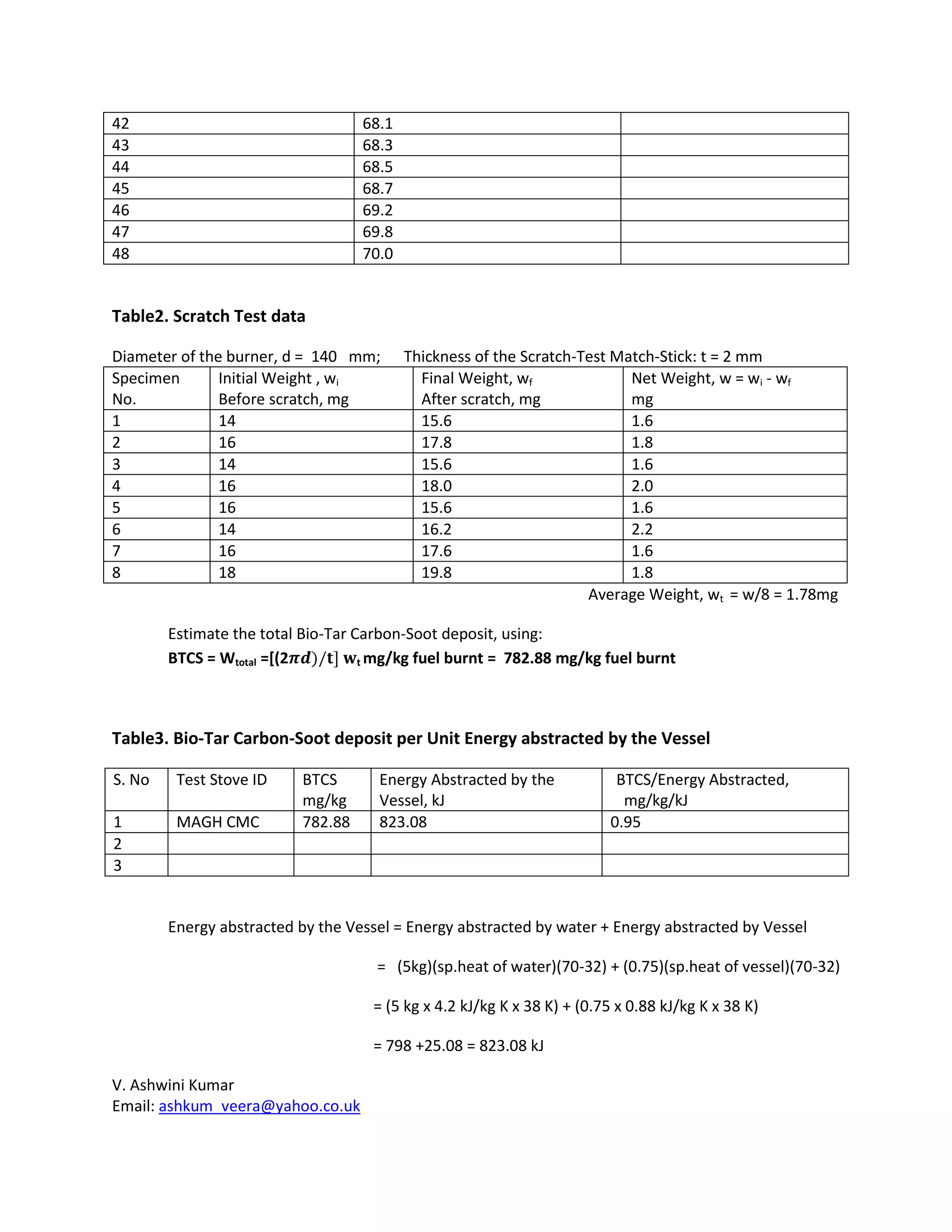

3. The results showed an average BTCS deposit of 1.78 mg per matchstick, corresponding to a total deposit of 782.88 mg per kg of wood fuel burned.