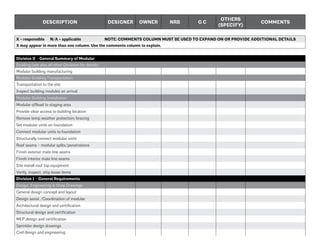

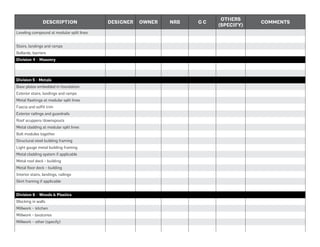

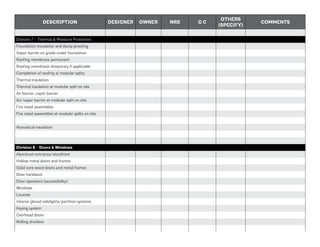

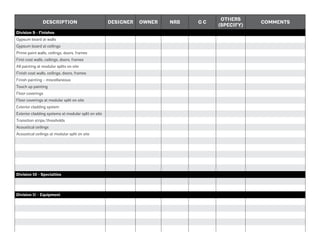

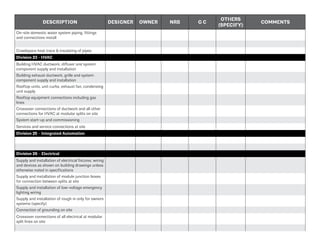

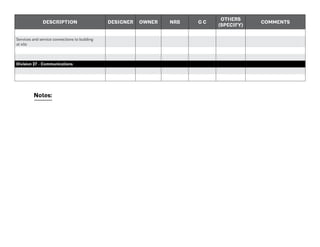

This document is a responsibility matrix that defines the scope of work and assigns responsibilities for all elements of a modular/off-site construction project to the project team, including the owner, designers, modular company, general contractor, and others. It covers responsibilities from design and manufacturing through transportation, installation, and final commissioning at the site. The matrix can be modified as needed and is intended to ensure all project elements are addressed and properly assigned.