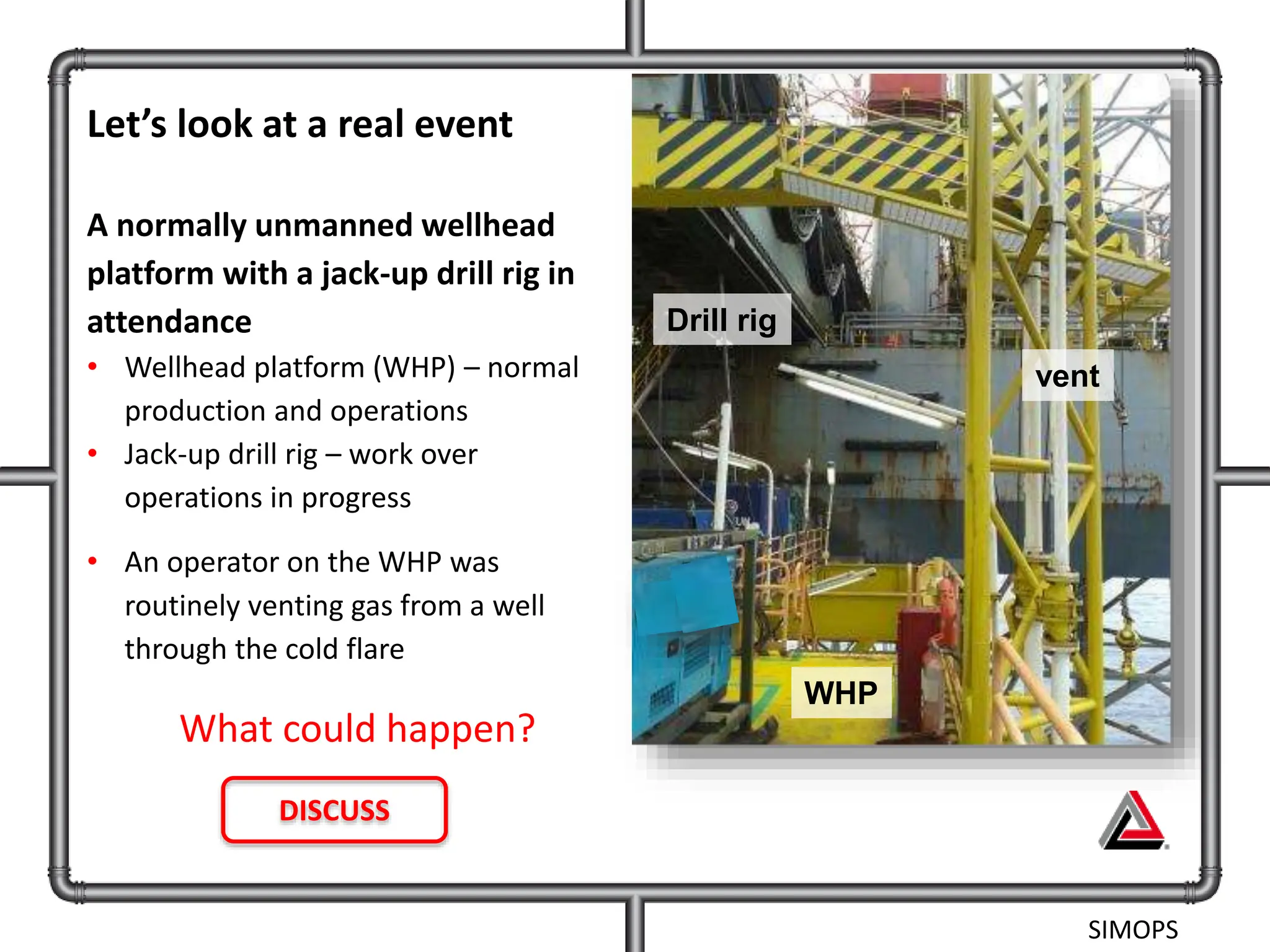

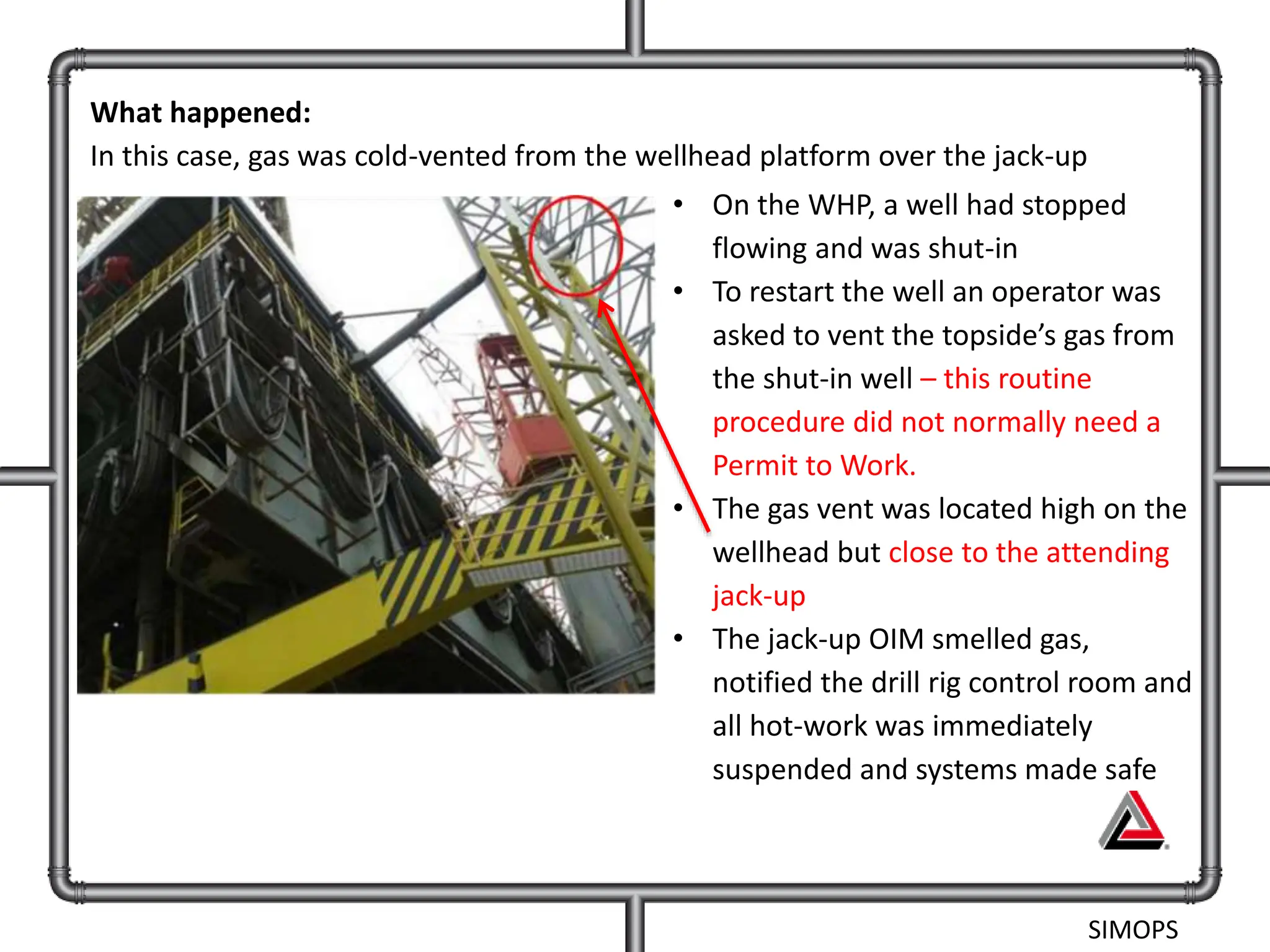

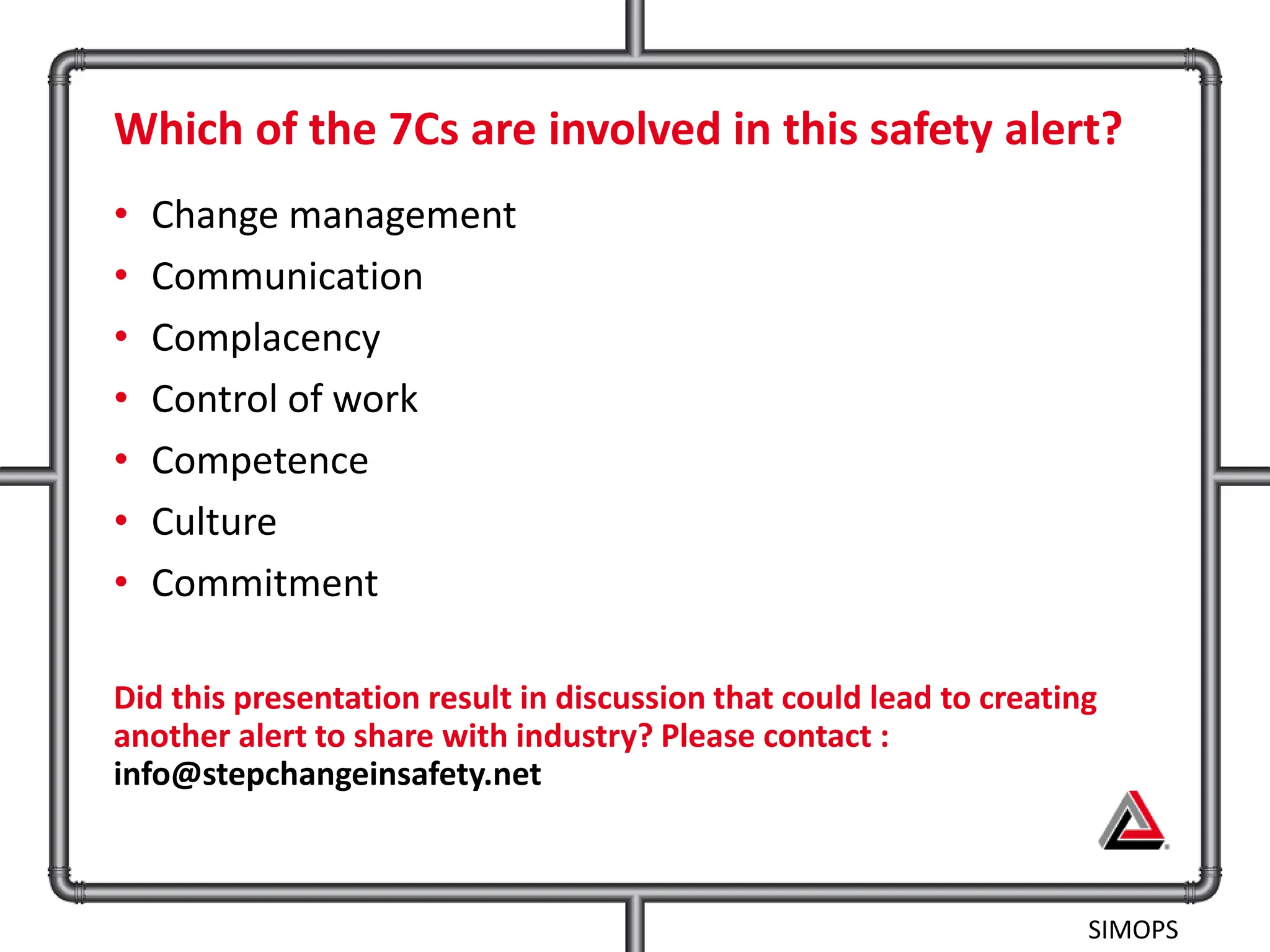

This document discusses the hazards of simultaneous operations (SIMOPS) between an unmanned wellhead platform and a drilling rig. It describes an incident where gas was vented from the wellhead platform during routine operations, without considering the presence of the nearby drilling rig. The gas vent was located close to the rig and could have caused an ignition if detected. Effective communication, risk assessment, and control of work procedures need to be established and followed for SIMOPS to prevent such incidents. Complacency and lack of change management contributed to this event.