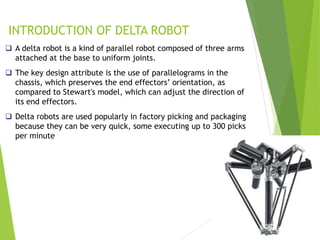

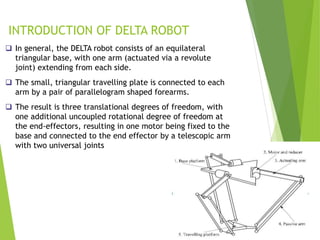

The document discusses Delta robots, which are parallel robots composed of three arms attached at a base with uniform joints. Delta robots are used popularly in factory picking and packaging because they can execute up to 300 picks per minute. A typical Delta robot consists of an equilateral triangular base with one arm extending from each side and connected to a small triangular traveling plate via parallelogram shaped forearms, resulting in three translational degrees of freedom and one additional rotational degree of freedom at the end effector. The document discusses applications of Delta robots in industries like packaging, medical/pharmaceutical, electronics assembly, and 3D printing. It also lists some common industrial Delta robots from manufacturers like ABB, Omron, Festo, and Fan