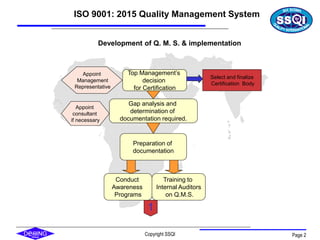

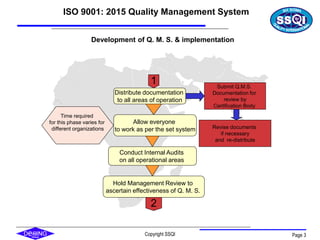

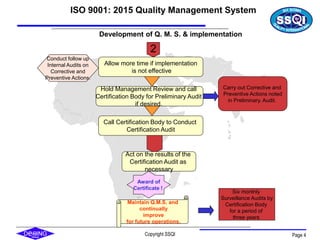

The document outlines the roadmap for ISO 9001:2015 certification, detailing the steps needed for the development and implementation of a Quality Management System (Q.M.S.). Key actions include top management's decision, gap analysis, documentation preparation, training, internal audits, and certification audits. It emphasizes the importance of continuous improvement and ongoing surveillance by the certification body after the initial certification.