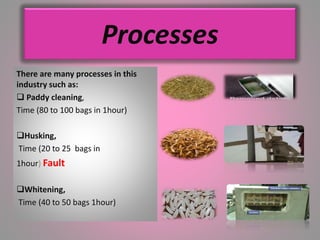

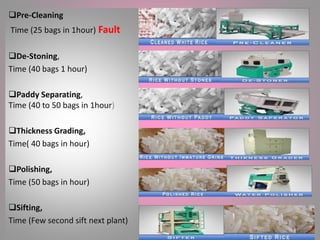

The document summarizes a report on Lucky Rice Mills production processes. It details the group members, varieties of rice produced, methodology used to collect data, production processes and time taken for each, yields and production capacities. It notes that production could be increased to 100,000 bags per year by upgrading husking machines, but pre-cleaning times are slowed by low quality machines, and production is sometimes stopped due to power outages or noise issues from damaged machines that require specialist repairs.