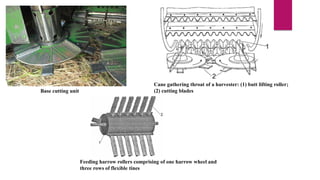

Manual sugarcane harvesting is labor intensive, requiring 850-1000 hours per hectare. Mechanical harvesters can be whole stalk or chopper systems. Whole stalk harvesters cut and windrow stalks, while chopper harvesters chop stalks into billets. Chopping increases juice deterioration while whole stalk harvesting has issues with bent stalks. Mini harvesters are self-propelled and suitable for varied field conditions. Mechanical harvesting increases efficiency but requires skilled labor and maintenance, while manual harvesting has issues with labor availability and costs.