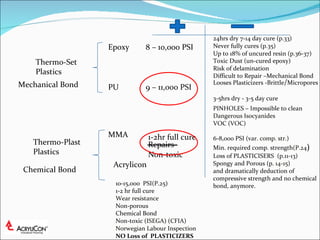

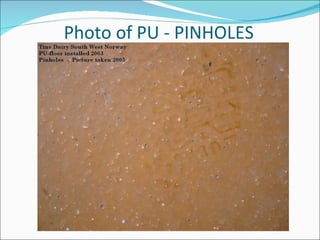

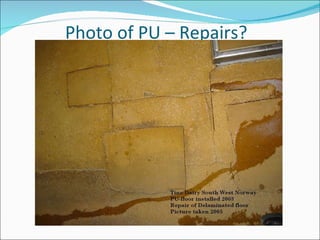

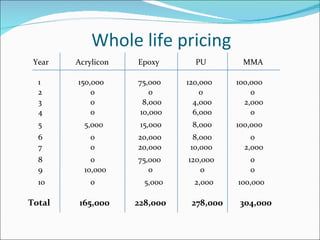

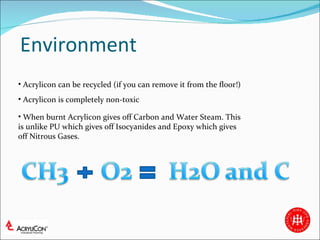

This document discusses different types of industrial flooring resins: epoxy, polyurethane (PU), methyl methacrylate (MMA), and acrylicon. It outlines their key performance characteristics like cure time, compressive strength, wear resistance, toxicity, and tendency to develop pinholes or lose plasticizers over time. Acrylicon is highlighted as having the lowest lifetime cost, being completely non-toxic, and producing less harmful emissions than epoxy or PU if burnt. The document aims to educate on factors to consider when specifying industrial flooring like longevity, hygiene, safety, and whole-life costs.