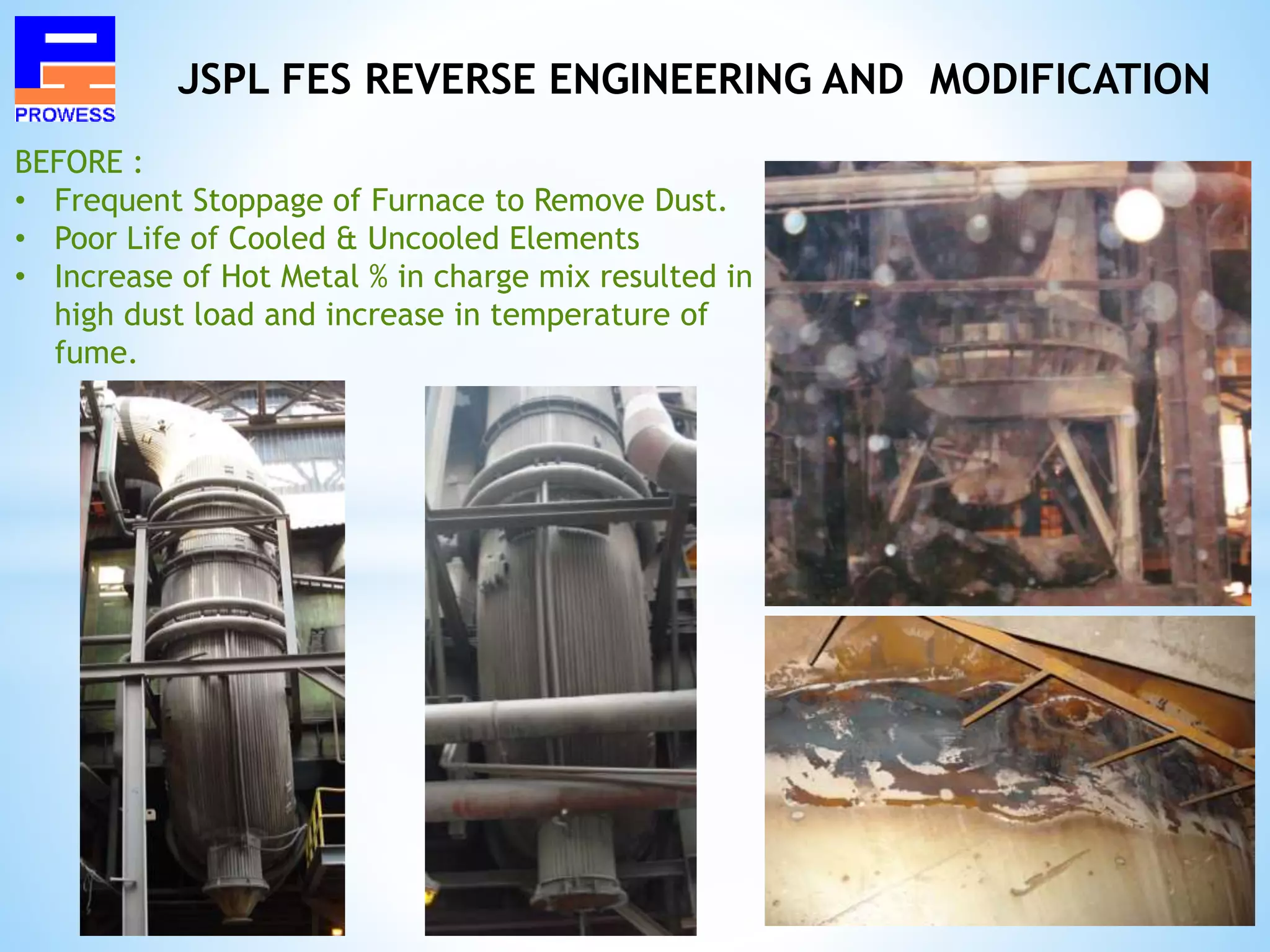

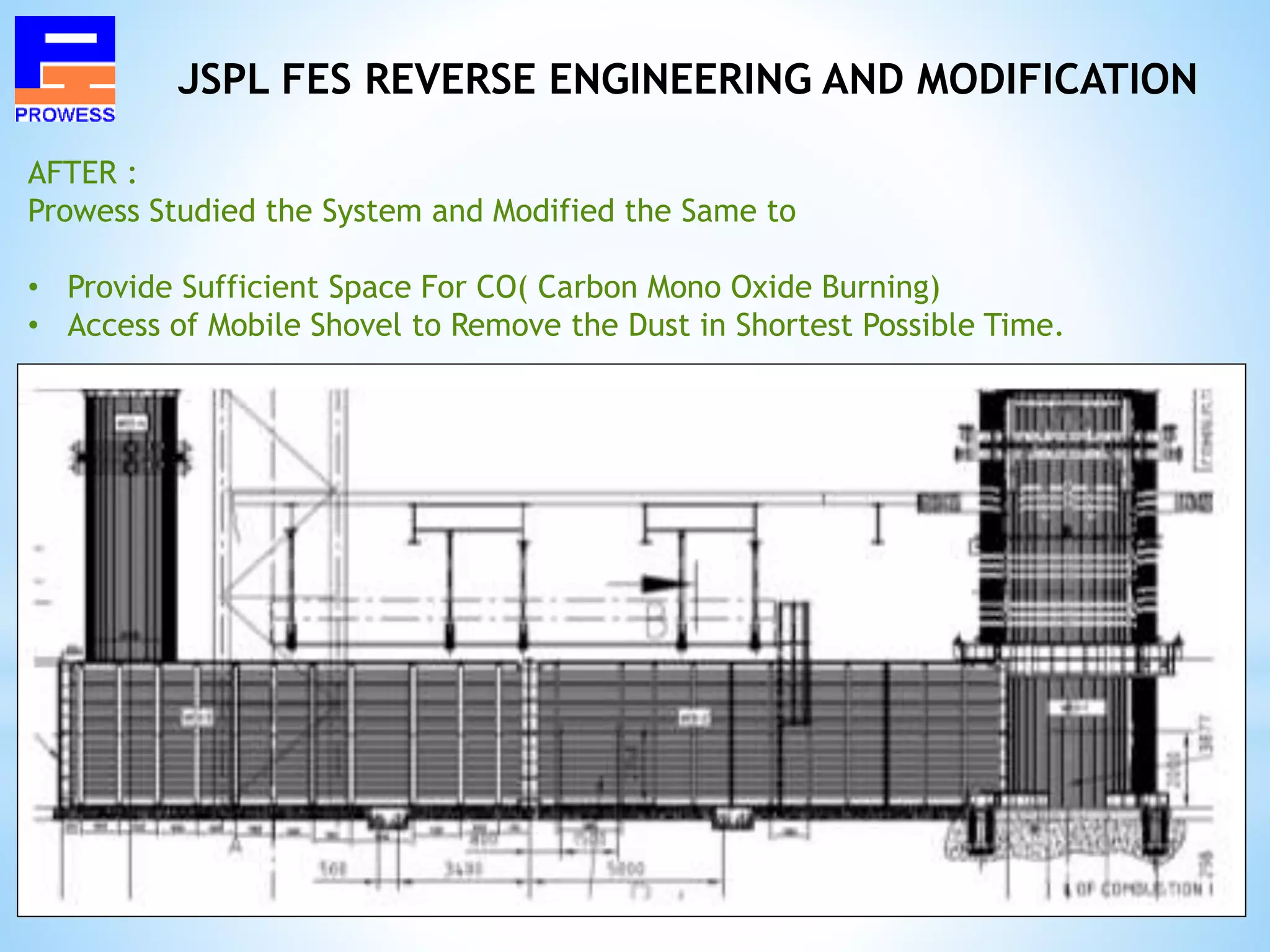

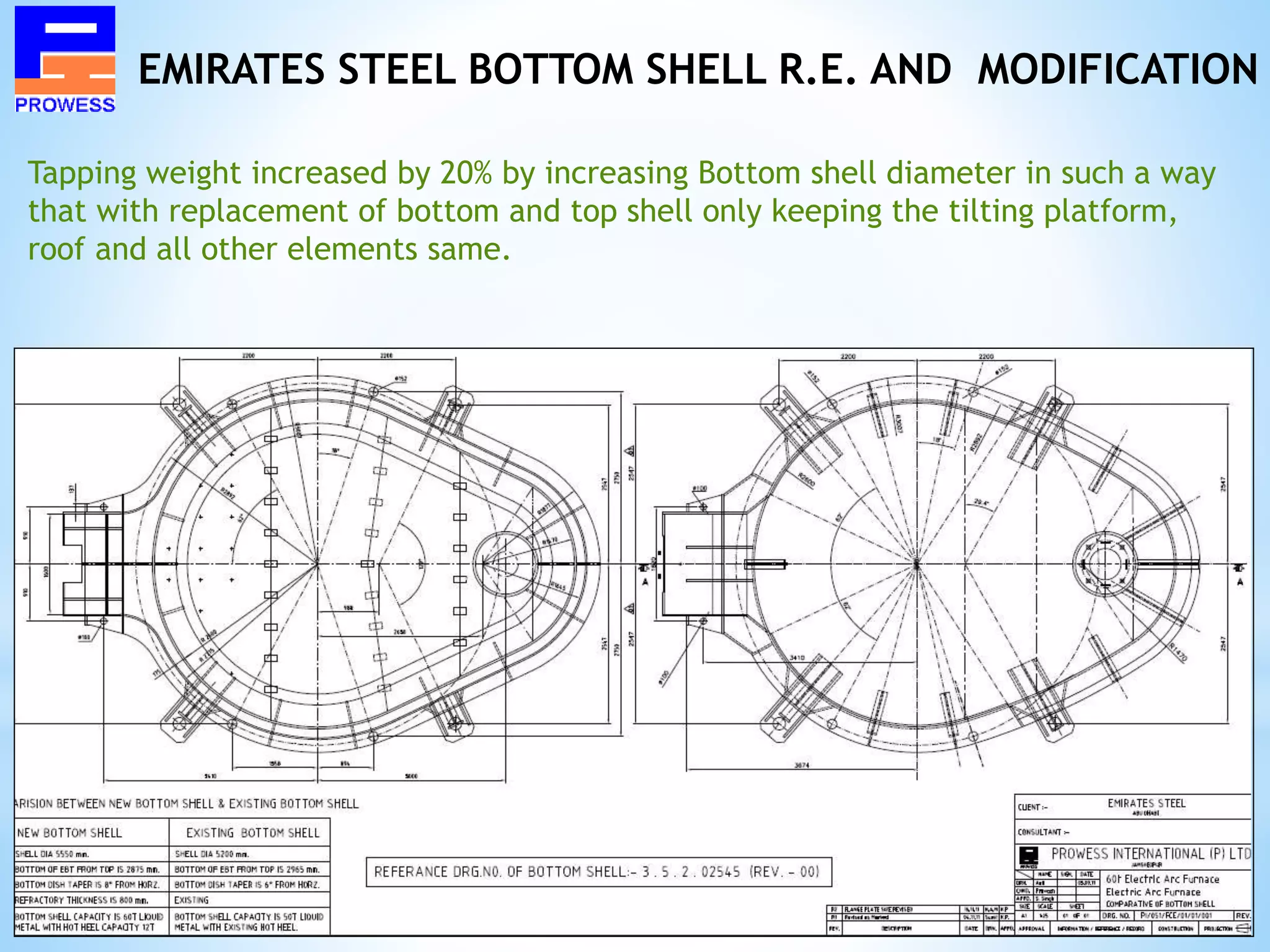

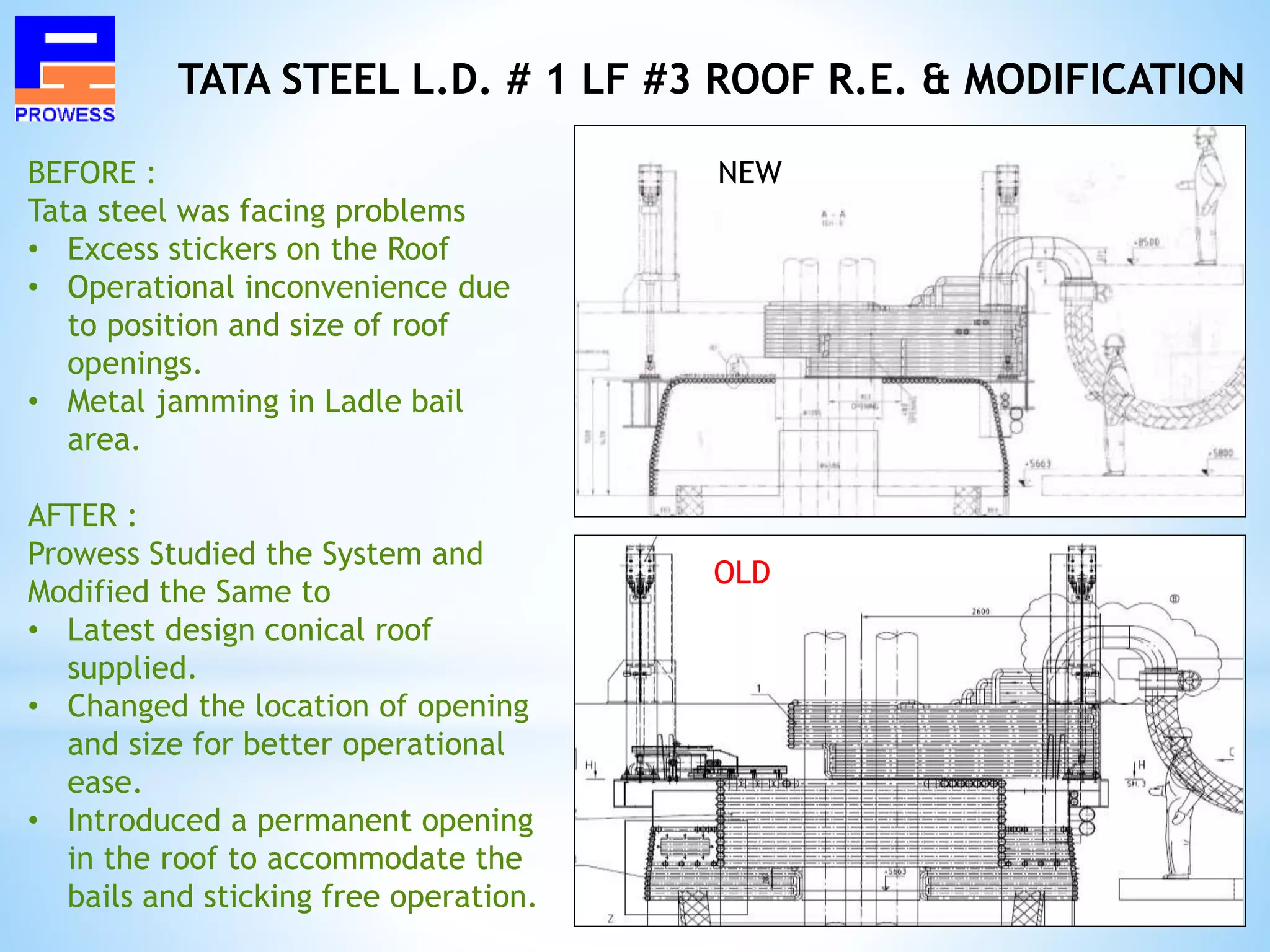

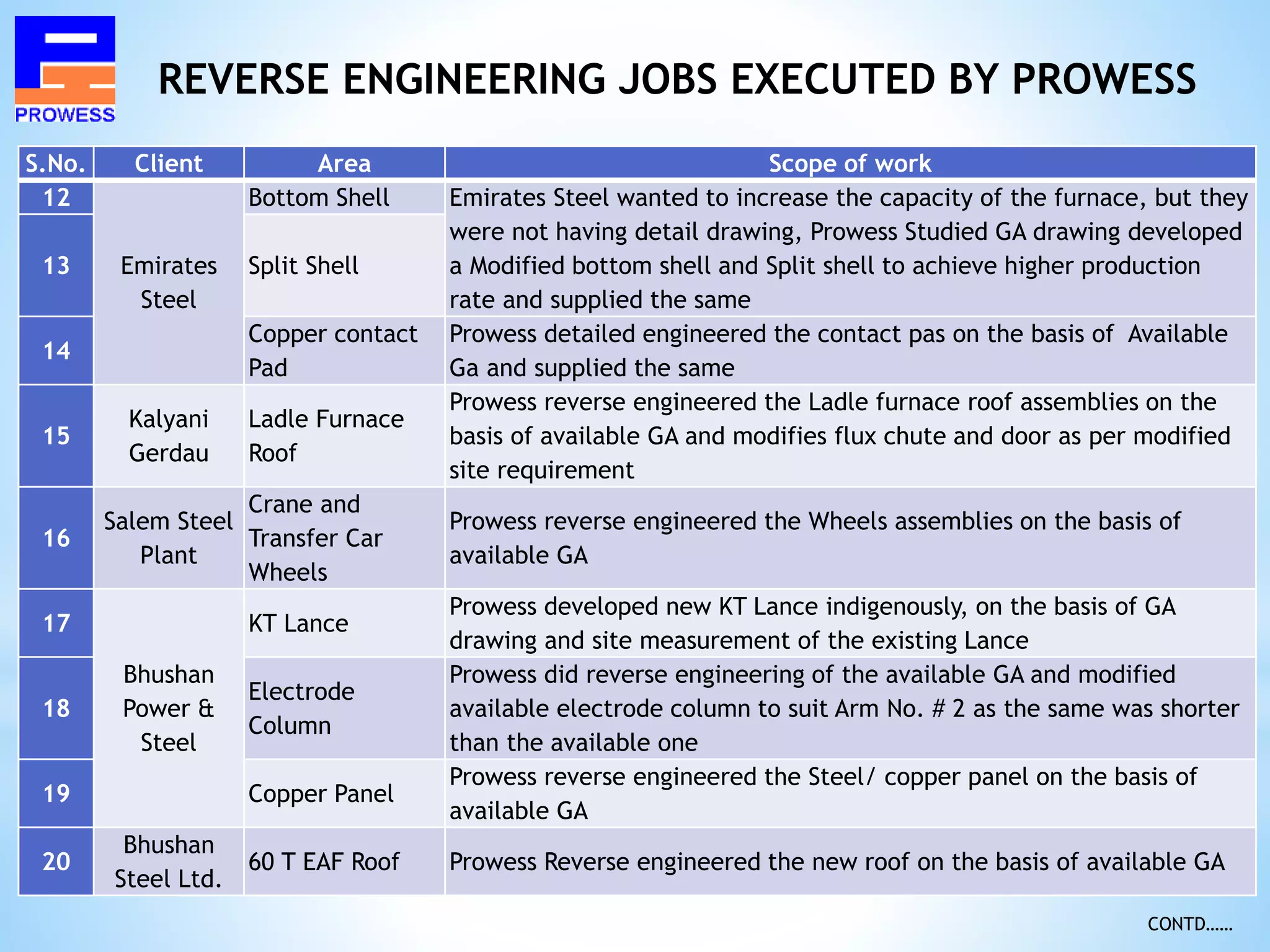

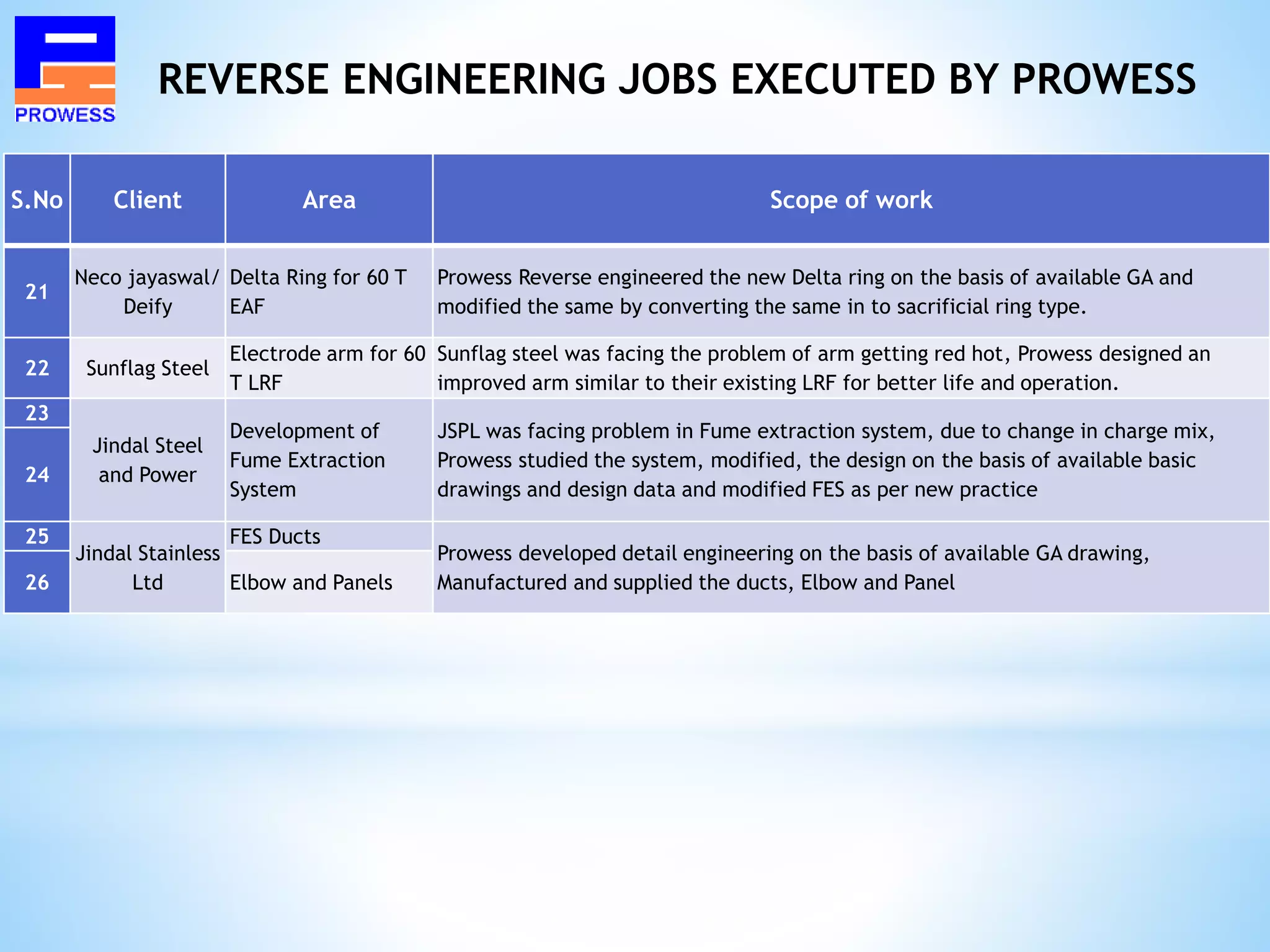

The document discusses several examples of reverse engineering and modification projects completed by Prowess for various steel plant clients. It provides details on modifications made to ladle furnace roofs, bottom shells, contact pads, wheels, lance designs, and fume extraction systems to address issues like increased production rates, operational ease, and changing charge mixes. The modifications were developed by studying existing designs and measurements and developing updated designs to meet new requirements.