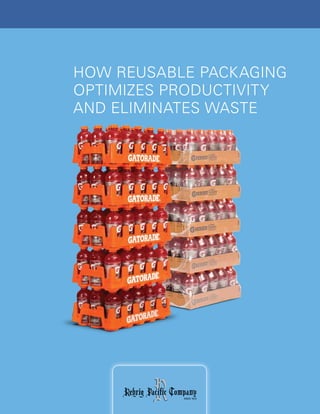

Rehrig Pacific's study on reusable packaging reveals significant productivity improvements and cost reductions in the supply chain for delivering small format beverages. Tests showed that using their reusable secondary packaging saved an average of 4 minutes and 51 seconds per delivery compared to traditional one-way packaging, amounting to substantial savings. Furthermore, the use of reusable packaging resulted in a zero trash footprint, enhanced sustainability, and boosted revenue through improved in-store marketing effectiveness.