This document provides information about reusable launch vehicles, specifically SpaceX's Falcon 9 Reusable (F9R) launch vehicle. It discusses SpaceX's goals of making spaceflight routine and affordable. The document describes the Falcon 9 family of launch vehicles and provides details on the technical specifications and design of the Falcon 9R first and second stages. It also discusses the payload fairing and Dragon spacecraft. Applications and advantages of reusable launch vehicles are presented.

![REUSABLE LAUNCH VEHICLE 2018-19

Dept. of Aeronautical Engineering, AIT Page 1

CHAPTER 1

INTRODUCTION

1.1 Company Description

SpaceX offers a family of launch vehicles that improve launch reliability and increase access

to space. The company was founded on the philosophy that simplicity, reliability and cost

effectiveness are closely connected. We approach all elements of launch services with a focus

on simplicity to both increase reliability and lower cost. The SpaceX corporate structure is

flat and business processes are lean, resulting in fast decision-making and product delivery.

SpaceX products are designed to require low-infrastructure facilities with little overhead,

while vehicle design teams are co-located with production and quality assurance staff to

tighten the critical feedback loop. The result is highly reliable and producible launch vehicles

with quality embedded throughout the process.

Established in 2002 by ELON MUSK, the founder of Tesla Motors, PayPal and the Zip2

Corporation, SpaceX has developed and flown the Falcon 1 light-lift launch vehicle, the

Falcon 9 medium-lift launch vehicle, and Dragon, which is the first commercially, produced

spacecraft to visit the International Space Station. SpaceX is also developing the Falcon

Heavy, a heavy-lift vehicle capable of delivering over 53 metric tons to orbit. Falcon Heavy’s

first flight is planned for 2016; it will be the most powerful operational rocket in the world by

a factor of two, and dragon, which is the first commercially produced spacecraft to visit the

international space station.

SpaceX has built a launch manifest that includes a broad array of commercial, government

and international customers. In 2008, NASA selected the SpaceX Falcon 9 launch vehicle

and Dragon spacecraft for the International Space Station Cargo Resupply Services contract.

NASA has also awarded SpaceX multiple contracts to develop the capability to transport

astronauts to space.

SpaceX has state-of-the-art production, testing, launch and operations facilities. SpaceX

design and manufacturing facilities are conveniently located near the Los Angeles

International Airport. This location allows the company to leverage Southern California’s

rich aerospace talent pool. The company also operates cutting-edge propulsion and structural

test facilities in Central Texas, along with launch sites in Florida and California, and the

world’s first commercial orbital launch site in development in South Texas.[1]](https://image.slidesharecdn.com/mergingresult-190314181924/75/Reusable-Launch-Vehicle-7-2048.jpg)

![REUSABLE LAUNCH VEHICLE 2018-19

Dept. of Aeronautical Engineering, AIT Page 5

Figure 2.2: Falcon Launch vehicle Family (source: SpaceX)

2.2 Falcon 9 Family

Falcon 9 is a family of two-stage-to-orbit launch vehicles[2]

, named for its use of nine

engines, designed and manufactured by SpaceX. The Falcon 9 versions are the Falcon 9 v1.0

(retired), Falcon 9 v1.1 (retired), and the current Falcon 9 full thrust, a reusable launch

system. Both stages are powered by rocket engines that burn liquid oxygen (LOX) and

rocket-grade kerosene (RP-1) propellants. The first stage is designed to be reusable, while the

second stage is not. The three Falcon 9 versions are in the medium-lift range of launch

systems. The current Falcon 9 (”full thrust upgrade”) can lift payloads of at least 13,150

kilograms to low Earth orbit, and at least 5,300 kilograms to geostationary transfer orbit. Full

payload capacity is kept private, and may vary depending on whether the first stage follows a

reusable or expendable flight profile.](https://image.slidesharecdn.com/mergingresult-190314181924/75/Reusable-Launch-Vehicle-11-2048.jpg)

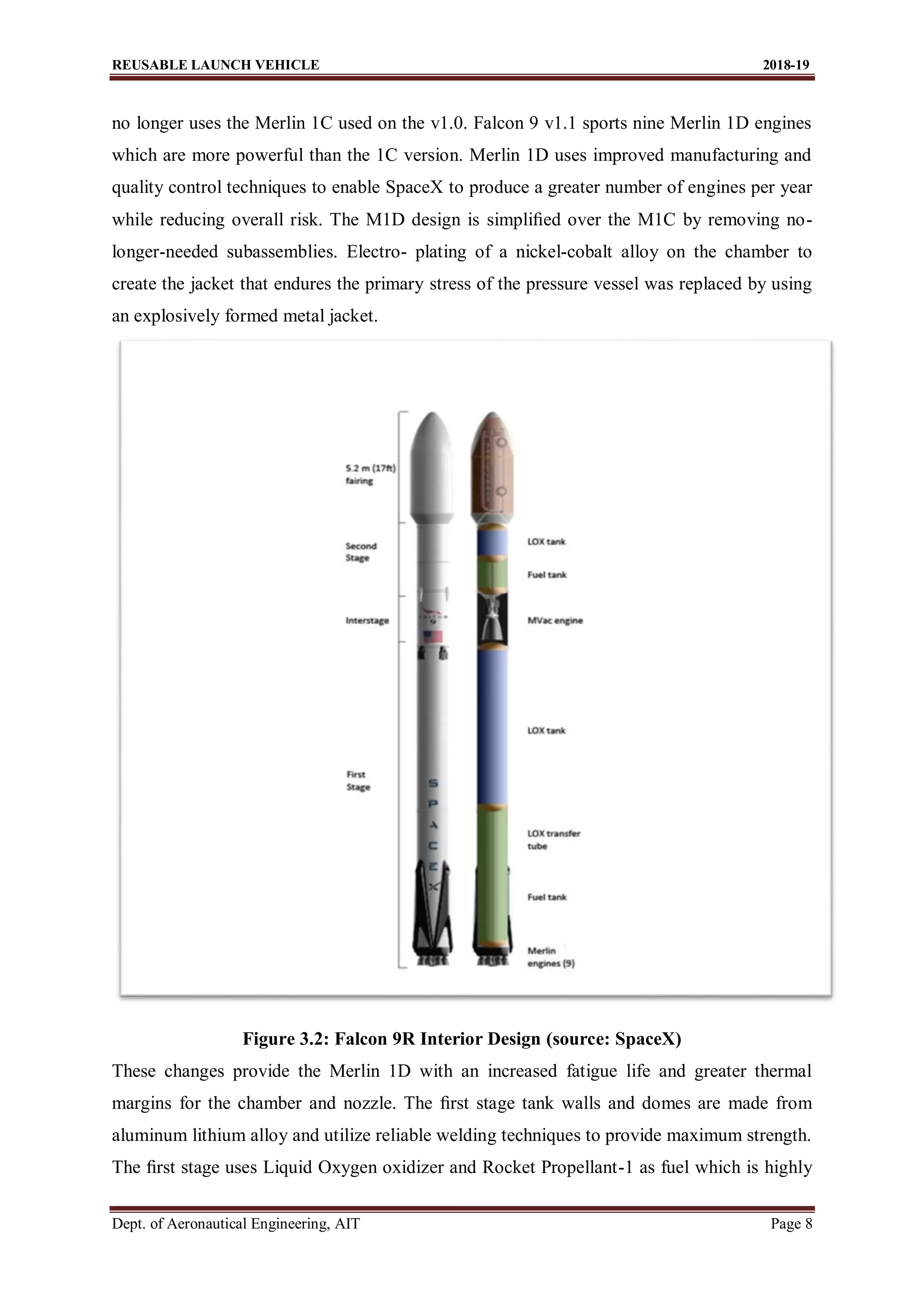

![REUSABLE LAUNCH VEHICLE 2018-19

Dept. of Aeronautical Engineering, AIT Page 6

CHAPTER 3

FALCON 9 REUSABLE LAUNCH VEHICLE DESCRIPTION

3.1 Falcon 9R Vehicle Overview

Falcon 9 full thrust-also known as Falcon 9 v1.1 Full Thrust[3],

and earlier as Falcon 9 v1.2,

Enhanced Falcon 9, Full-Performance Falcon 9, Upgraded Falcon 9, and Falcon 9 Upgrade is

the third major version of the SpaceX Falcon 9 orbital launch. Designed in 2014-2015, it

began launch operations in December 2015, and has a large manifest of over 40 launches

contracted over the next five years. In 21 December 2015, the full thrust version of the Falcon

9 was the first launch vehicle on an orbital trajectory to successfully vertically a first stage

and recover the rocket, following an extensive technology development program in 2011-

2015 that had developed some of the technology on Falcon 9 v1.0 and Falcon 9 v1.1 launch

vehicle first stages. Falcon 9 full thrust is a substantial upgrade over the older Falcon 9 v1.1

rocket, which flew its last mission in January 2016. With updated first- and second-stage

engines, larger second-stage propellant tankage, and propellant densification, the vehicle can

carry substantial payload to geostationary orbit and perform a propulsive landing for

recovery.

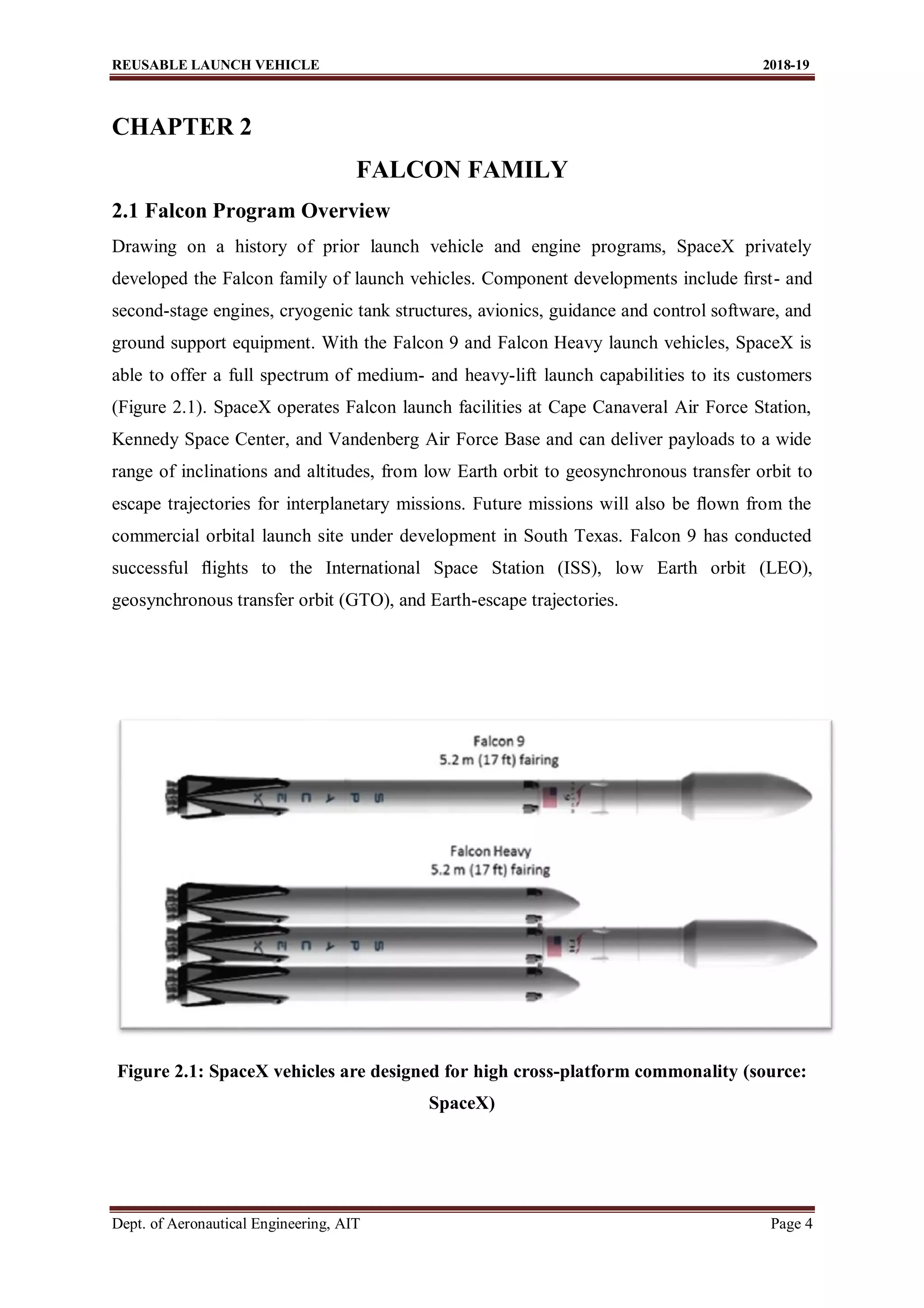

3.2 Falcon 9 Reusable Launch vehicle Specifications

Falcon 9 (Figure 3.1) is a two-stage launch vehicle powered by liquid oxygen (LOX) and

rocket-grade kerosene (RP-1). The vehicle is designed, built and operated by SpaceX. Falcon

9 can be flown with a fairing or with a SpaceX Dragon spacecraft. All first-stage and second-

stage vehicle systems are the same in the two configurations; only the payload interface to the

second stage changes between the fairing and Dragon configurations. Falcon 9 v1.1 is a two-

stage launch vehicle that stands 68.4 meters tall, is 3.66 meters in diameter with a liftoff mass

of 505,846 Kilograms when flying in its F9R version with re-usable first stage. The launcher

can deliver payloads of up to 13,150 Kilograms to Low Earth Orbit and 4,850kg to

Geostationary Transfer Orbit. Aiming to become a re-usable launcher, Falcon 9’s first stage is

modified with a reaction control system, four grid fins for steering and four deployable

landing legs.](https://image.slidesharecdn.com/mergingresult-190314181924/75/Reusable-Launch-Vehicle-12-2048.jpg)

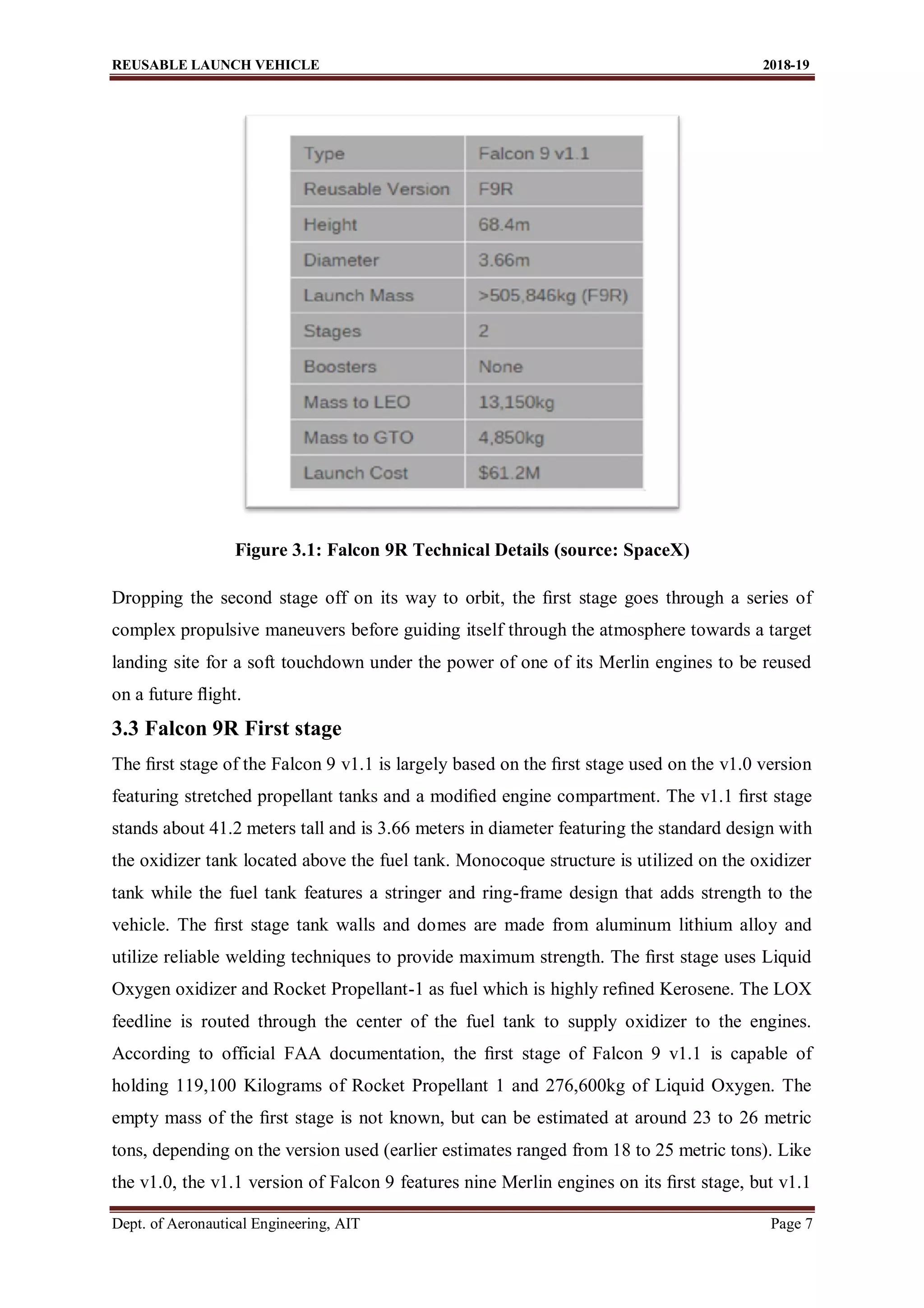

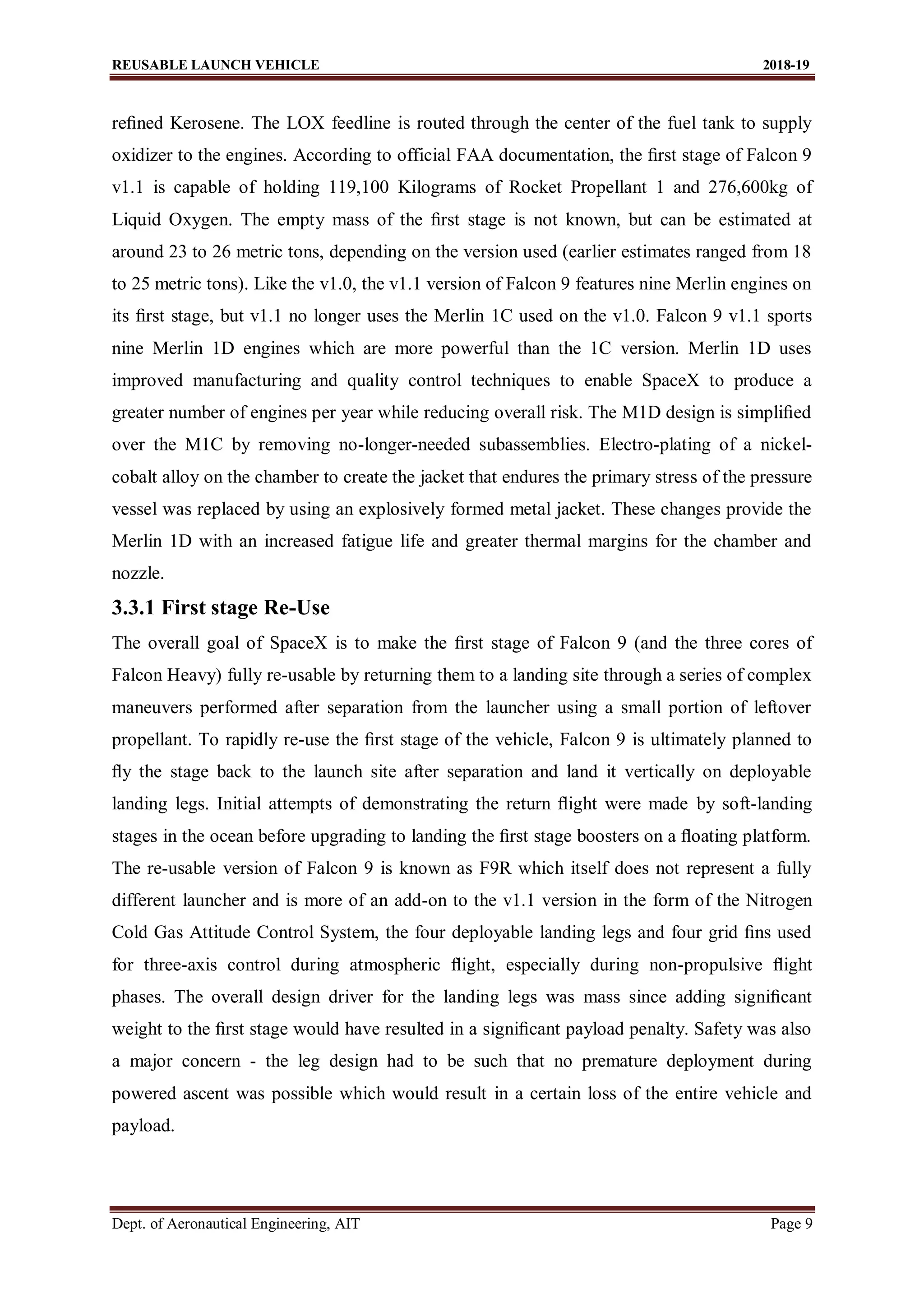

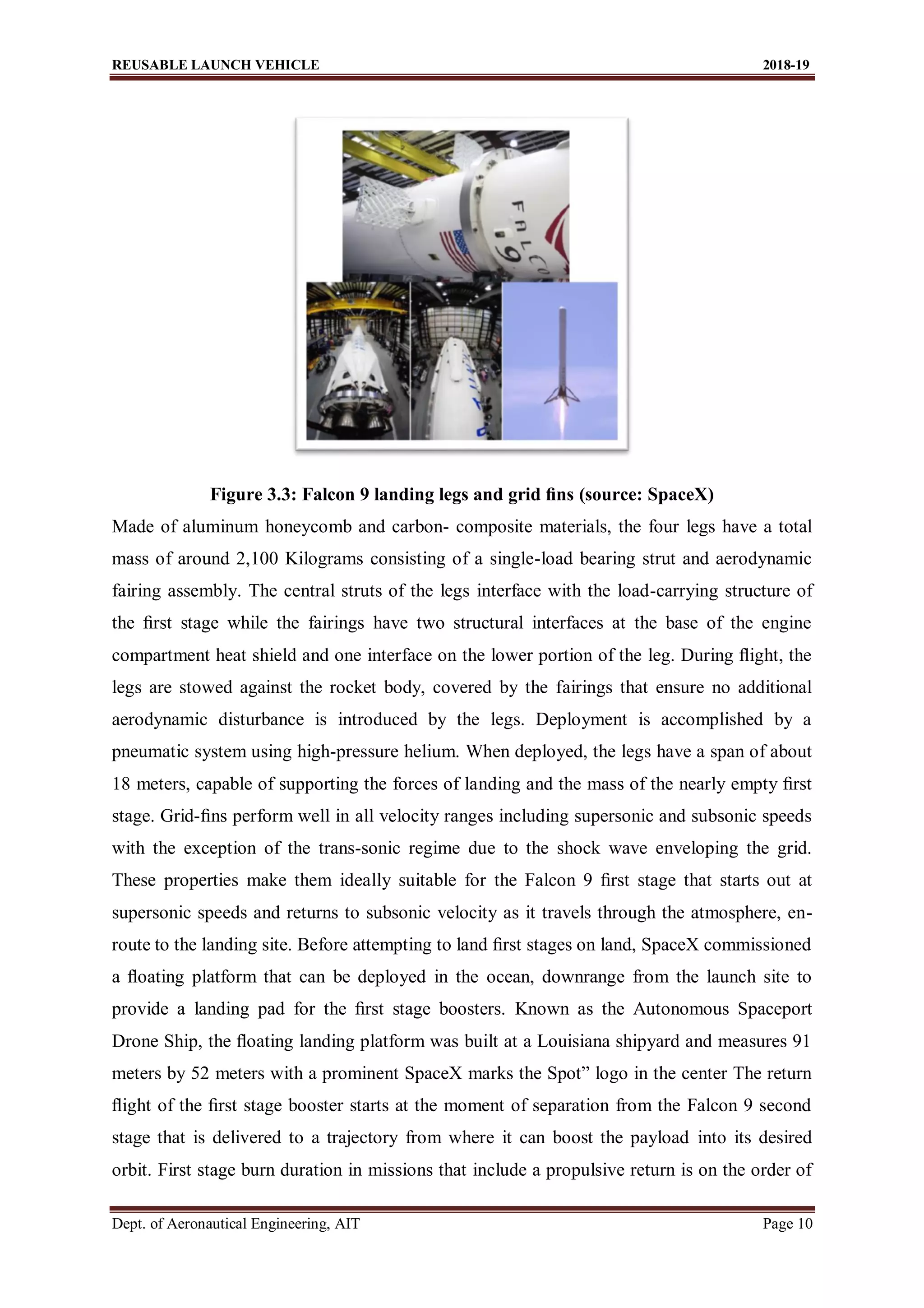

![REUSABLE LAUNCH VEHICLE 2018-19

Dept. of Aeronautical Engineering, AIT Page 15

CHAPTER 5

FALCON 9 OVERVIER

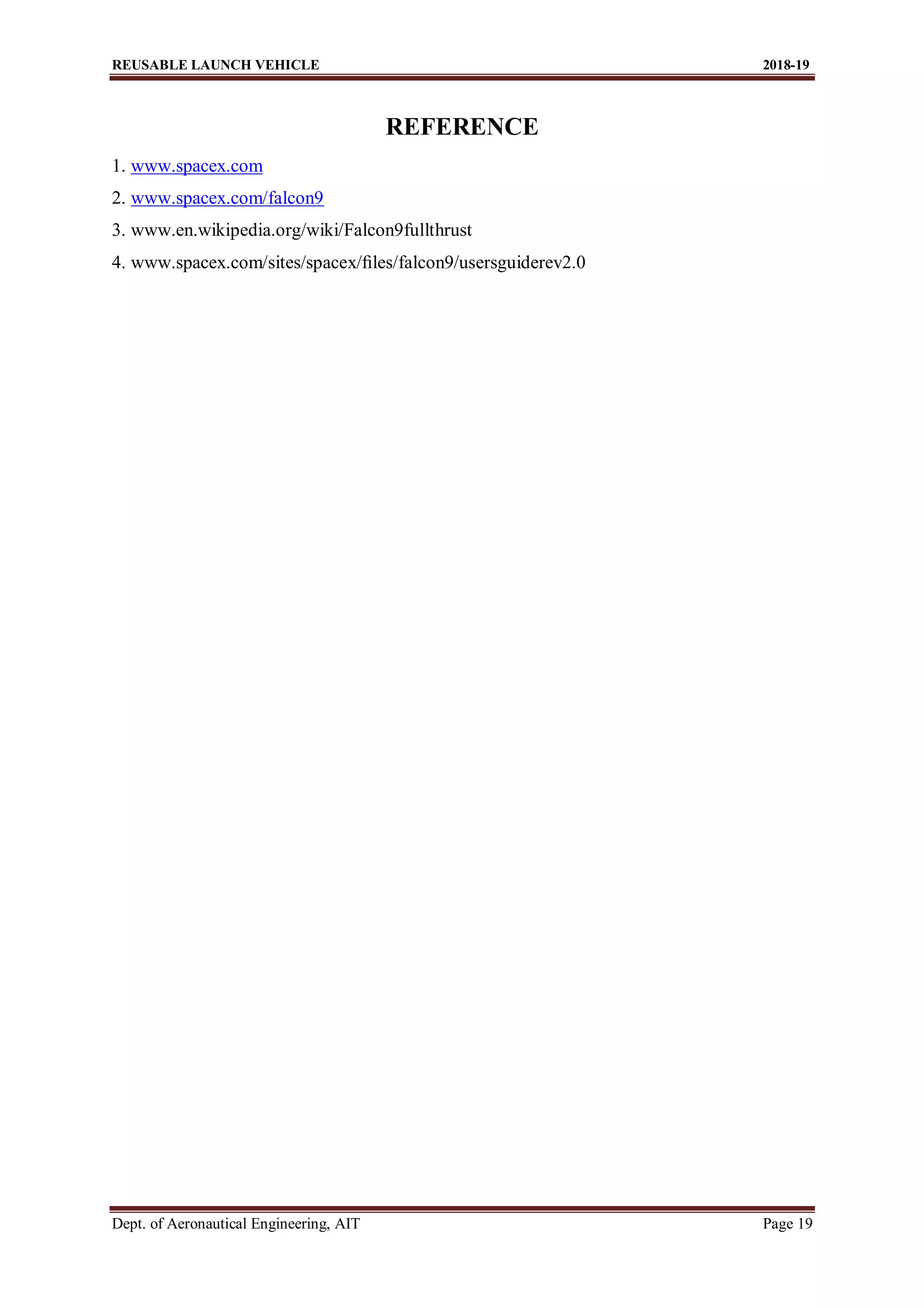

5.1 Falcon launch vehicle safety

We continue to push the limits of rocket technology as we design the safest crew

transportation system ever flown while simultaneously advancing toward fully reusable

launch vehicles. Our emphasis on safety has led to advancements such as increased structural

factors of safety[4]

, greater redundancy and rigorous fault mitigation

5.2 Retention, Release and Separation Systems

The first and second stages are mated by mechanical latches at three points between the top

of the interstage and the base of the second-stage fuel tank. After the first-stage engine shut

down, a high- pressure helium circuit is used to release the latches via redundant actuators.

For added reliability, a redundant center pusher attached to the first stage is designed to

dramatically decrease the probability of re-contact between the stages following separation.

5.3 Programming in F9R

The Flight Software team is about 35 people. We write all the code for Falcon 9,

Grasshopper, and Dragon applications; and do the core platform work, also on those vehicles;

we also write simulation software; test the flight code; write the communications and analysis

software, deployed in our ground stations. We also work in Mission Control to support active

missions. The Ground Software team is about 9 people. We primarily code in Lab VIEW. We

develop the GUIs used in Mission and Launch control, for engineers and operators to monitor

vehicle telemetry and command the rocket, spacecraft, and pad support equipment. We are

pushing high bandwidth data around a highly distributed system and implementing complex

user interfaces with strict requirements to ensure operators can control and evaluate

spacecraft in a timely manner. SpaceX uses an Actor-Judge system to provide triple

redundancy to its rockets and spacecraft. The Falcon 9 has 3 dual core x86 processors

running an instance of Linux on each core. The flight software is written in C/C++ and runs

in the x86 environment. For each calculation/decision, the”flight string” compares the results

from both cores. If there is a inconsistency, the string is bad and doesn’t send any commands.

If both cores return the same response, the string sends the command to the various

microcontrollers on the rocket that control things like the engines and grid fins. The

microcontrollers, running on PowerPC processors, received three commands from the three

flight strings. They act as a judge to choose the correct course of actions. If all three strings](https://image.slidesharecdn.com/mergingresult-190314181924/75/Reusable-Launch-Vehicle-21-2048.jpg)