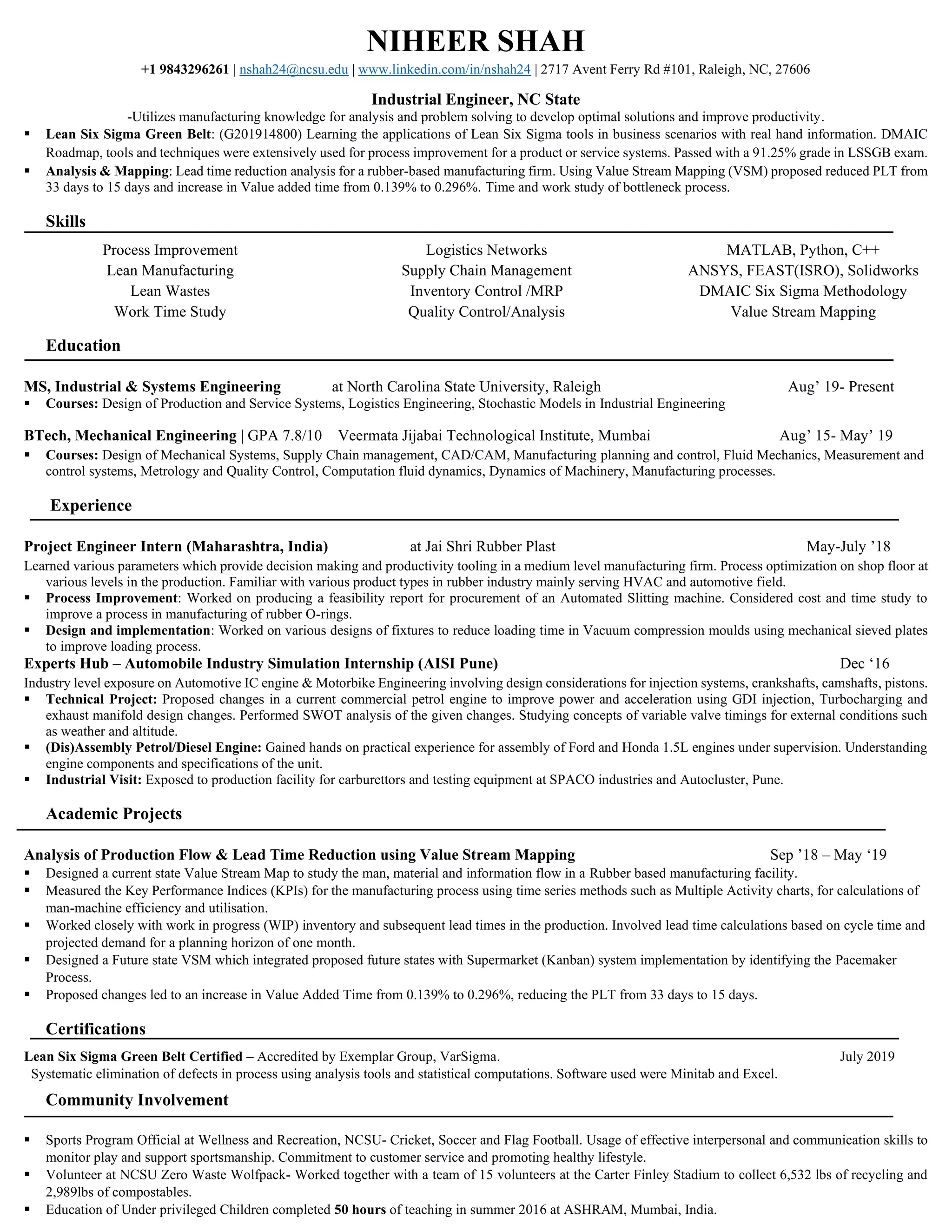

Niheer Shah is an industrial engineer at NC State University who has a Lean Six Sigma Green Belt certification. He has experience improving manufacturing processes through tools like value stream mapping and lead time reduction analysis. For one project, he reduced a rubber manufacturer's lead time from 33 to 15 days by increasing value-added time. Shah has skills in process improvement, lean manufacturing, quality control, and engineering software. He holds an MS in industrial engineering from NC State and a BTech in mechanical engineering.