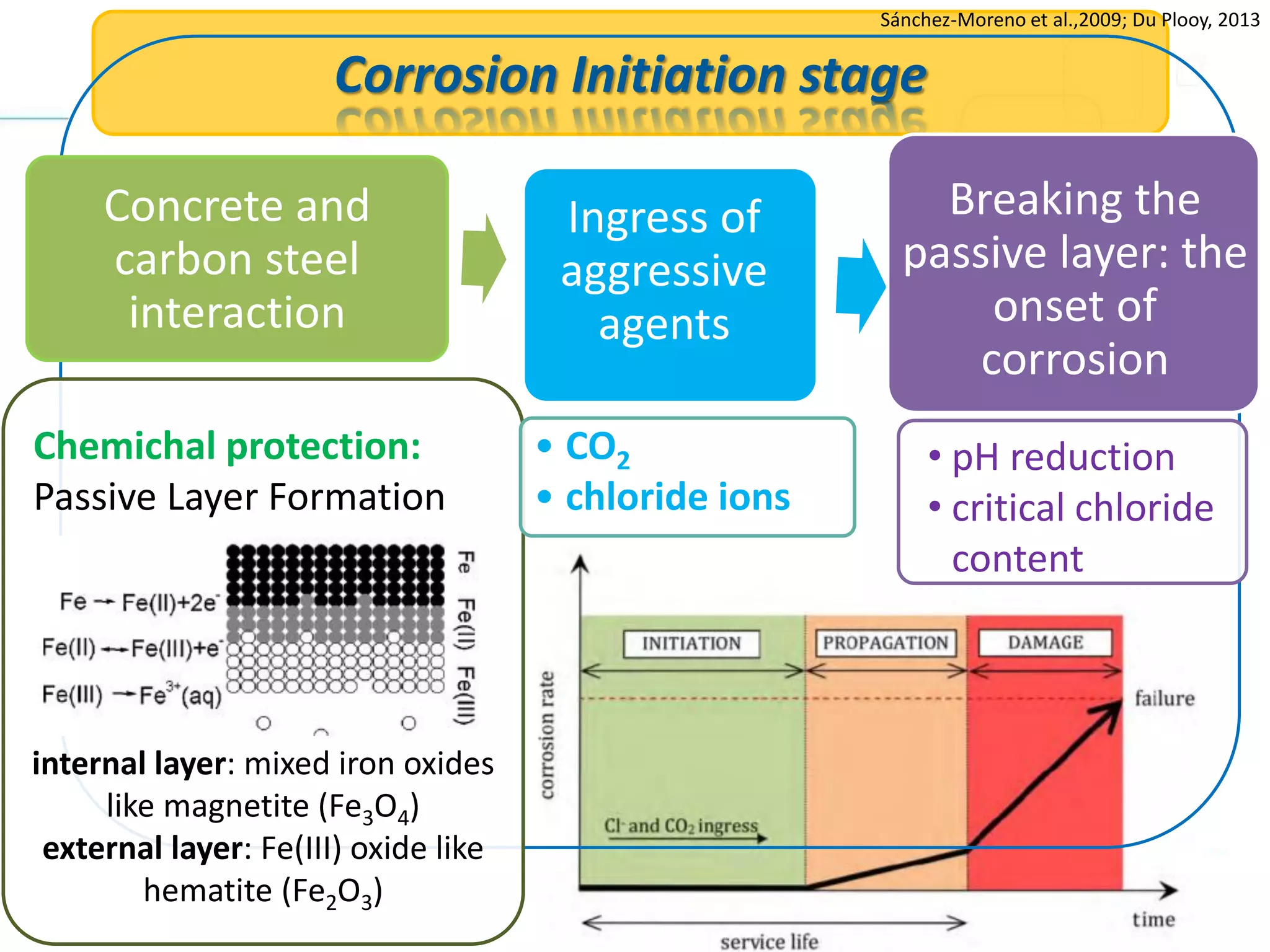

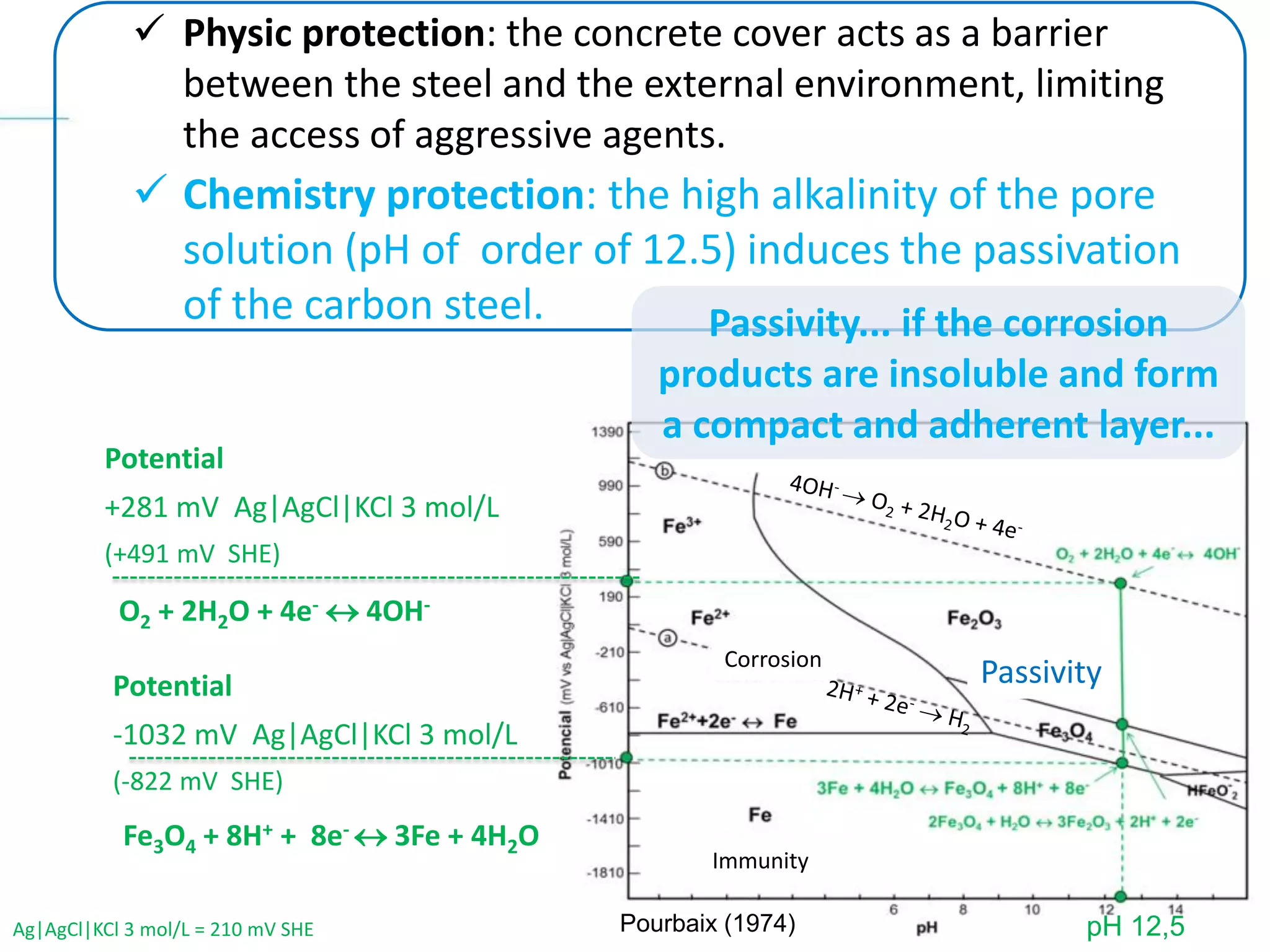

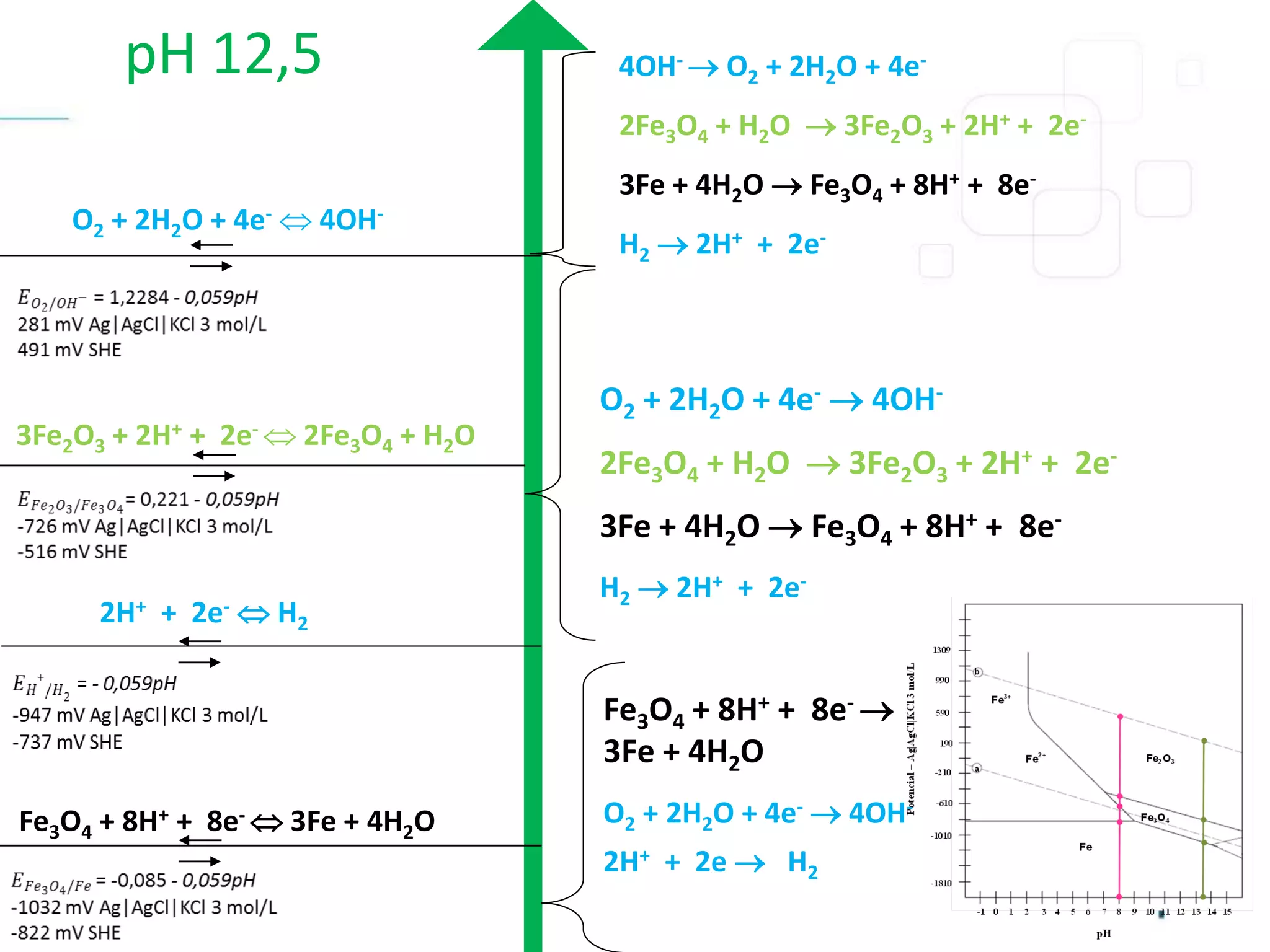

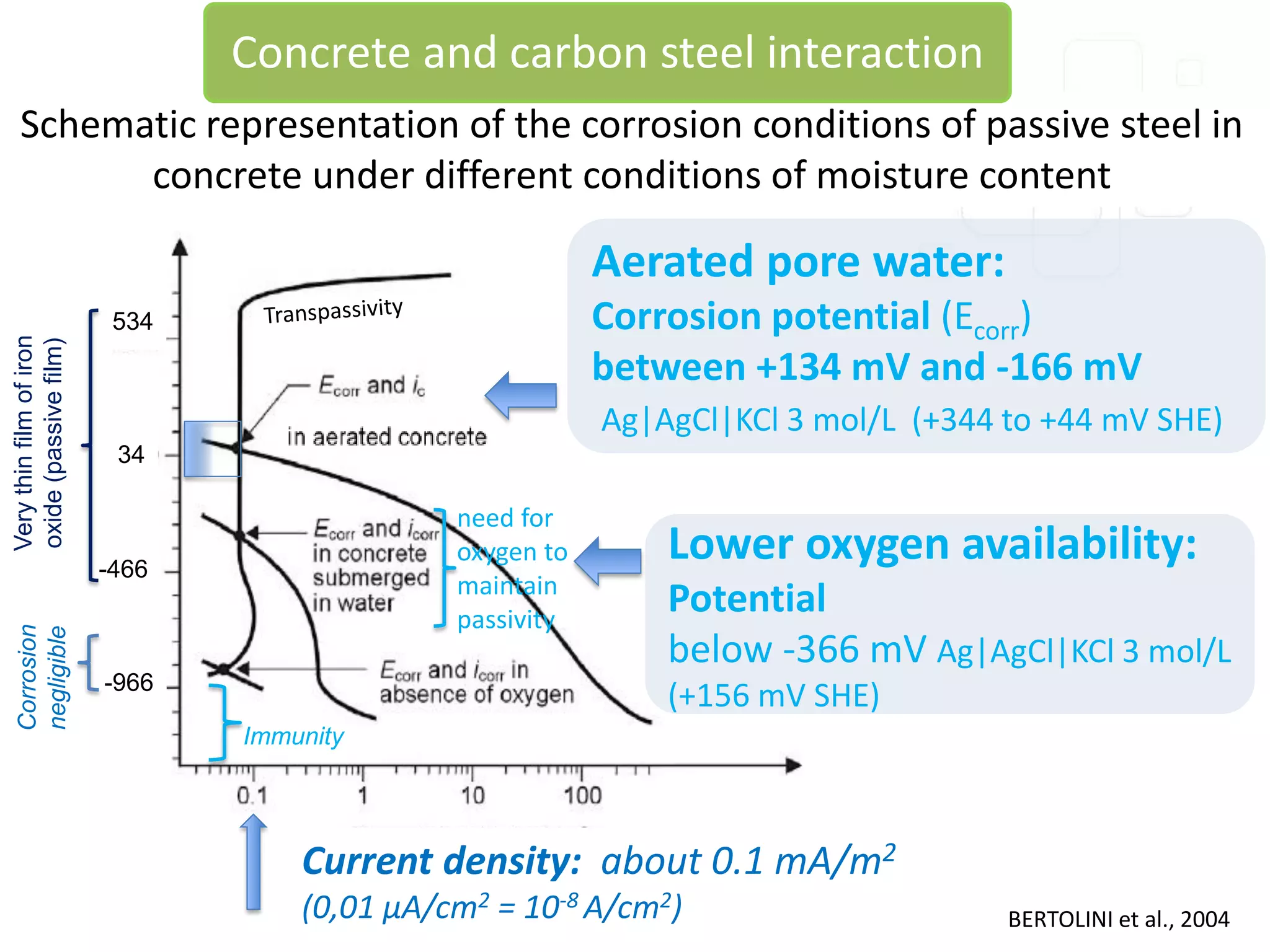

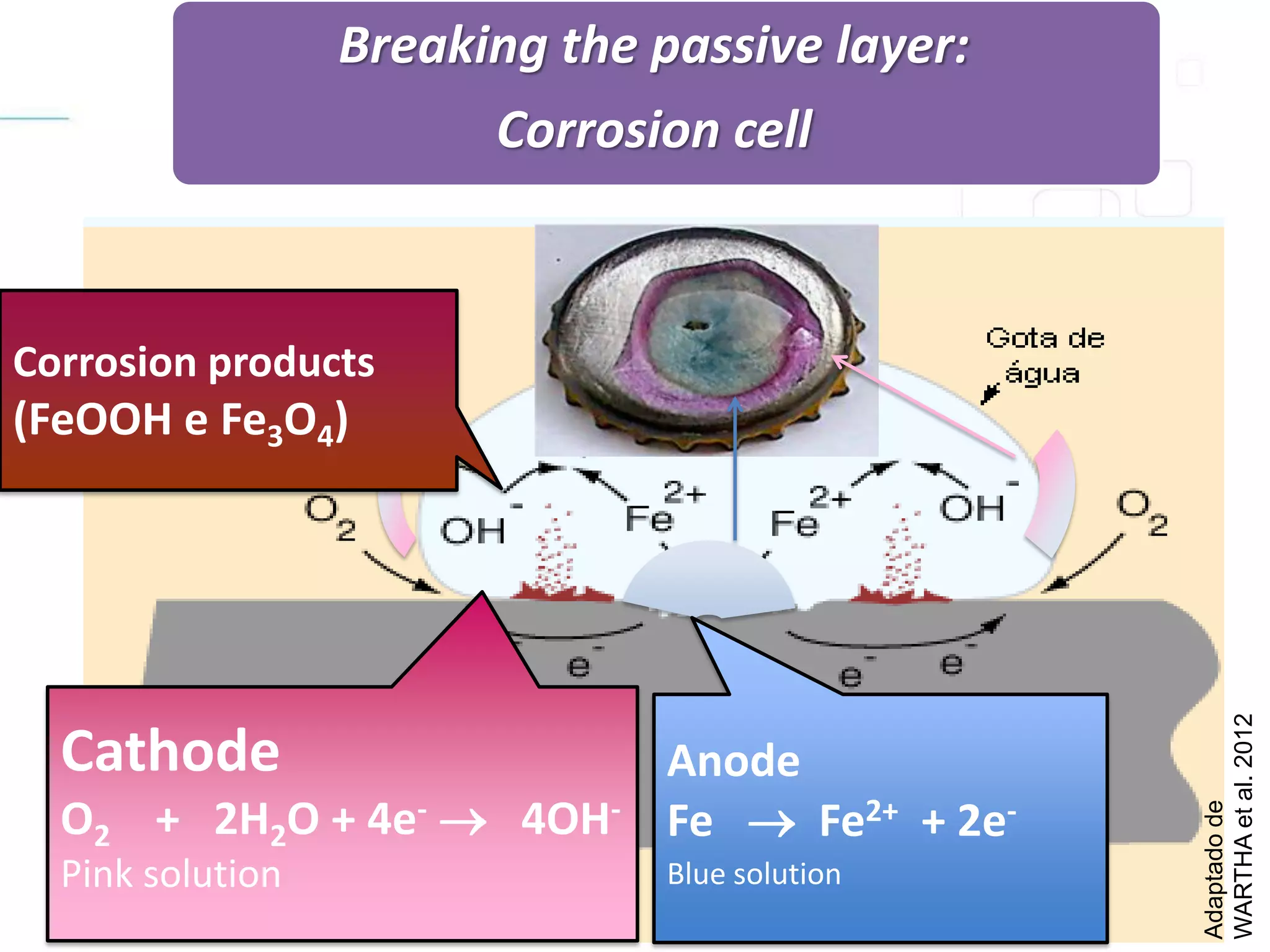

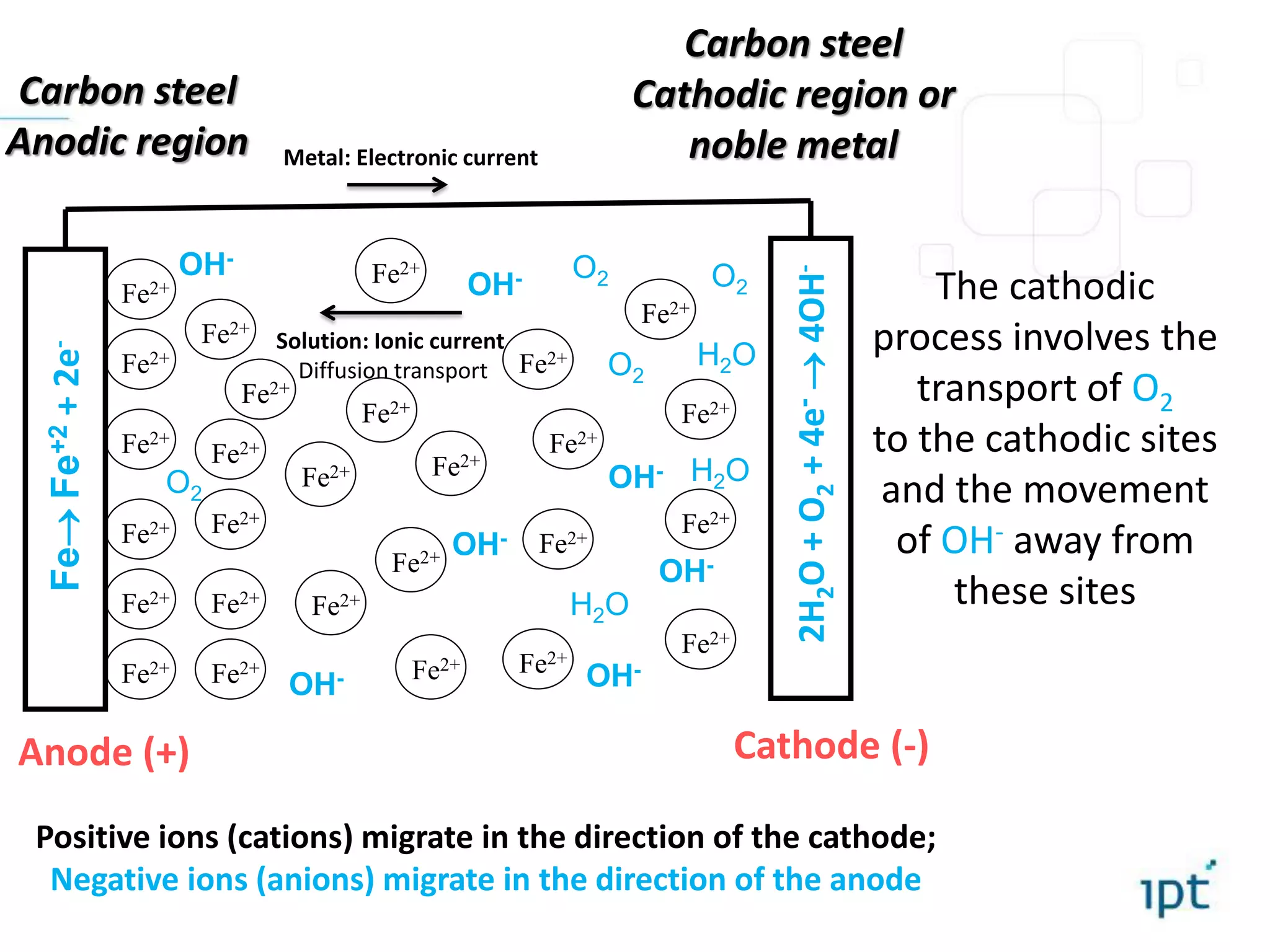

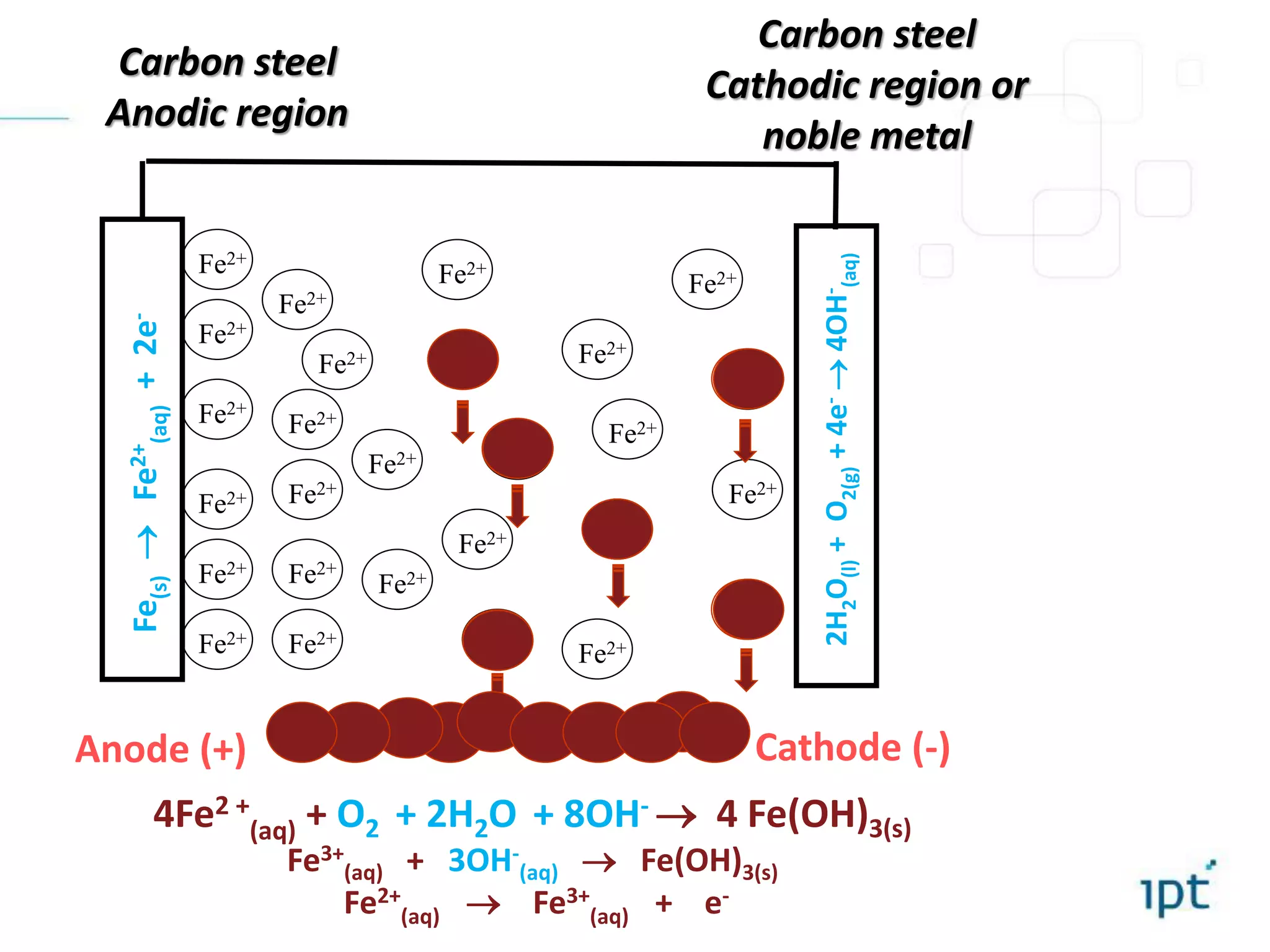

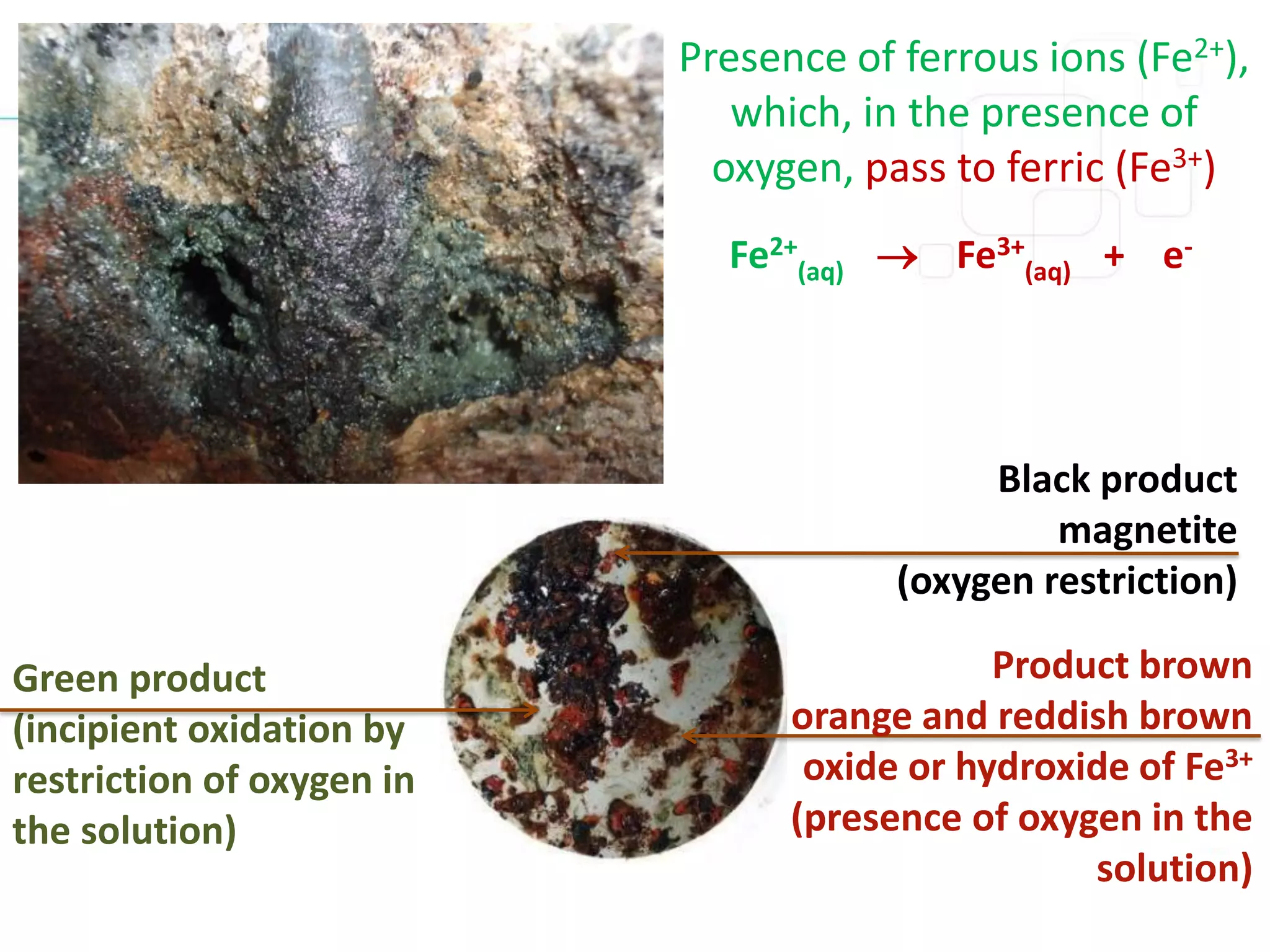

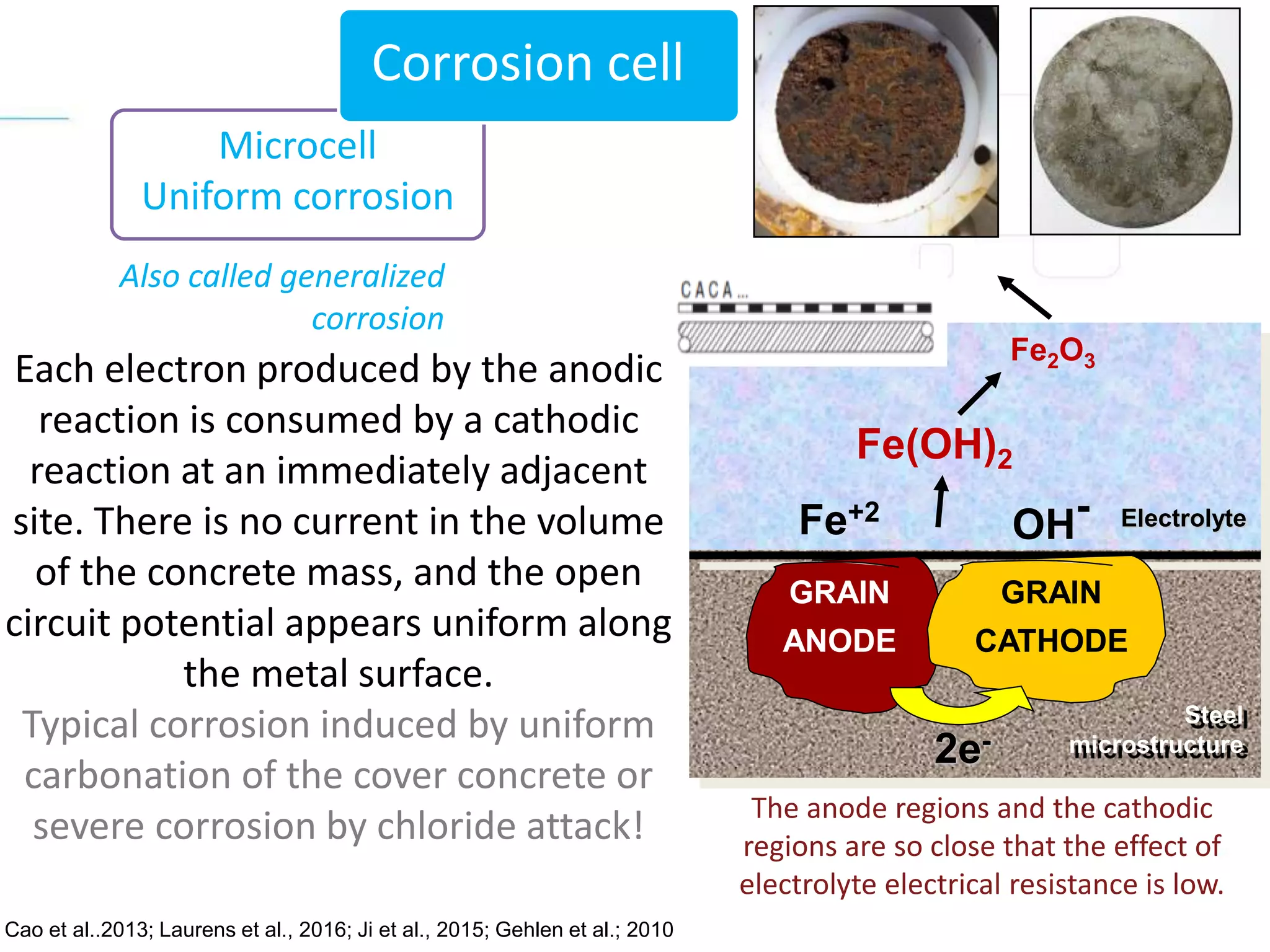

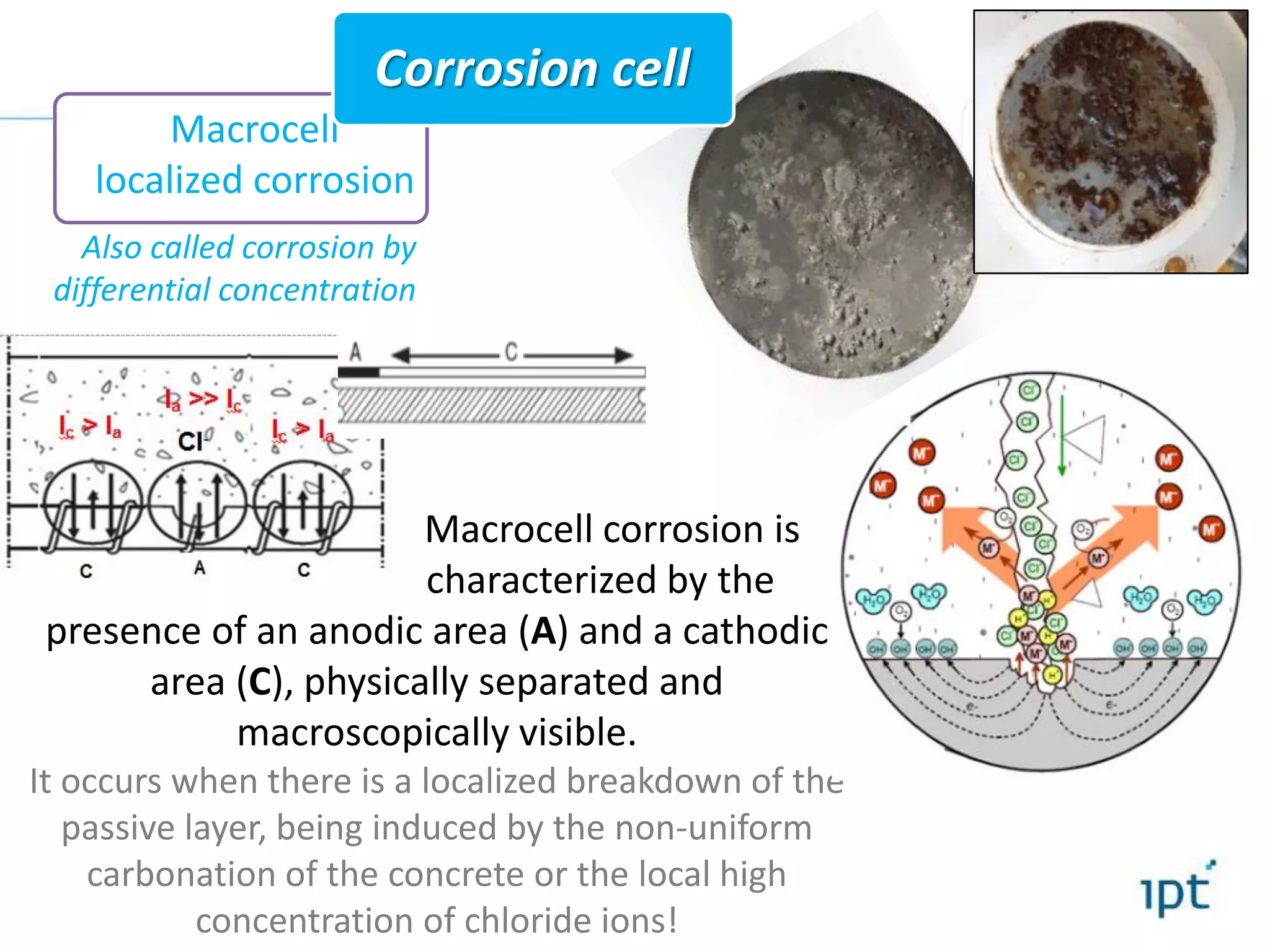

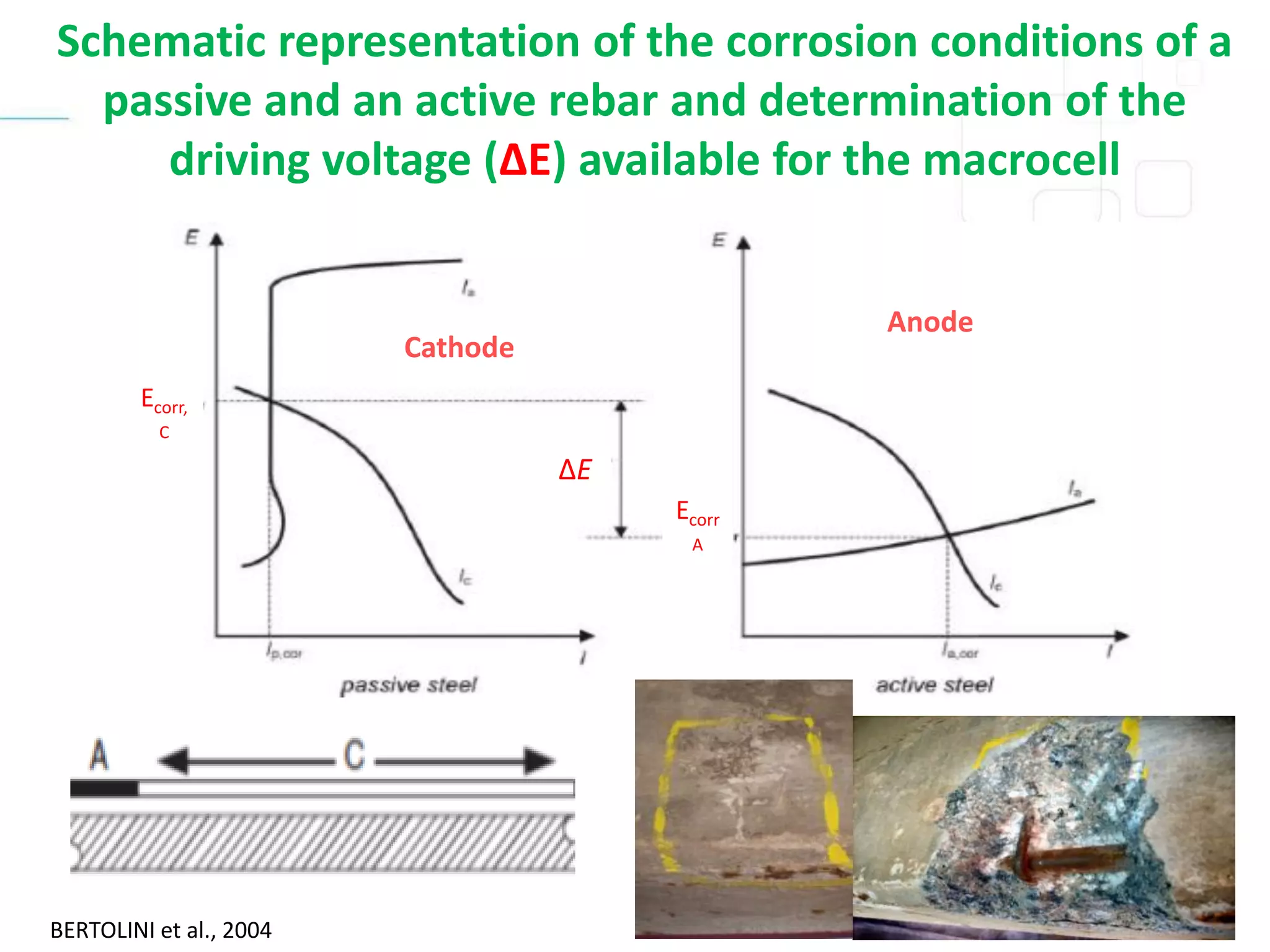

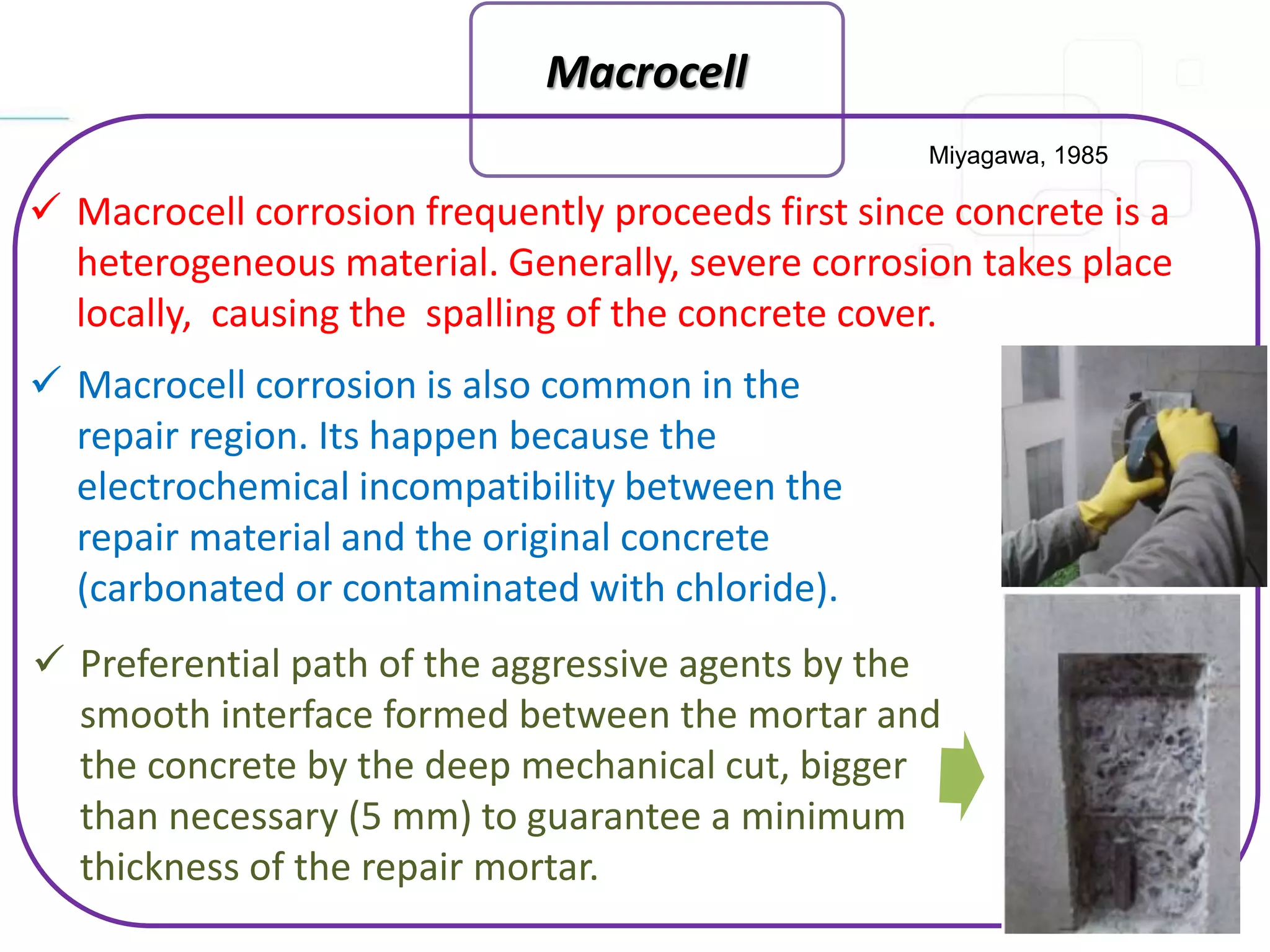

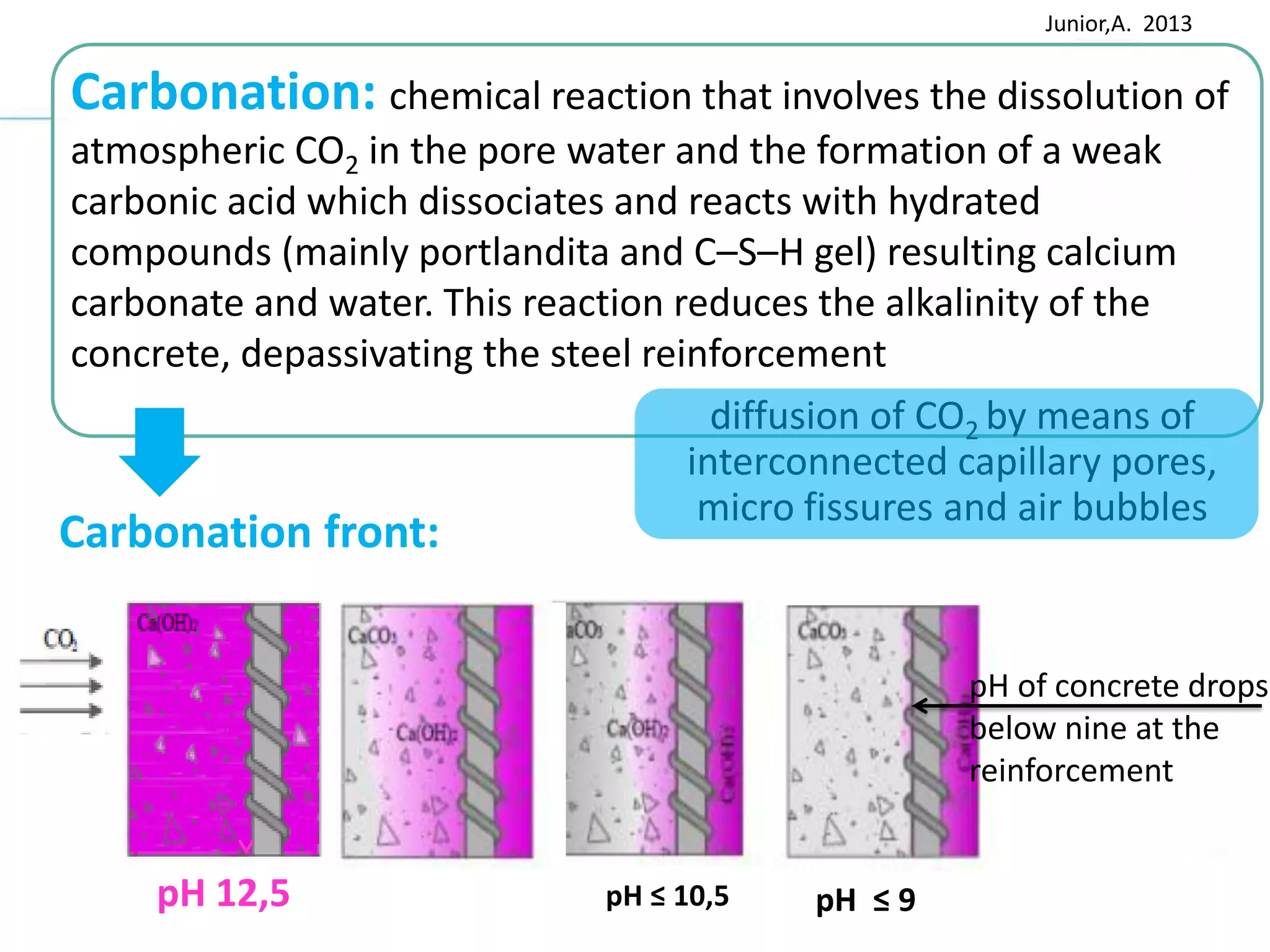

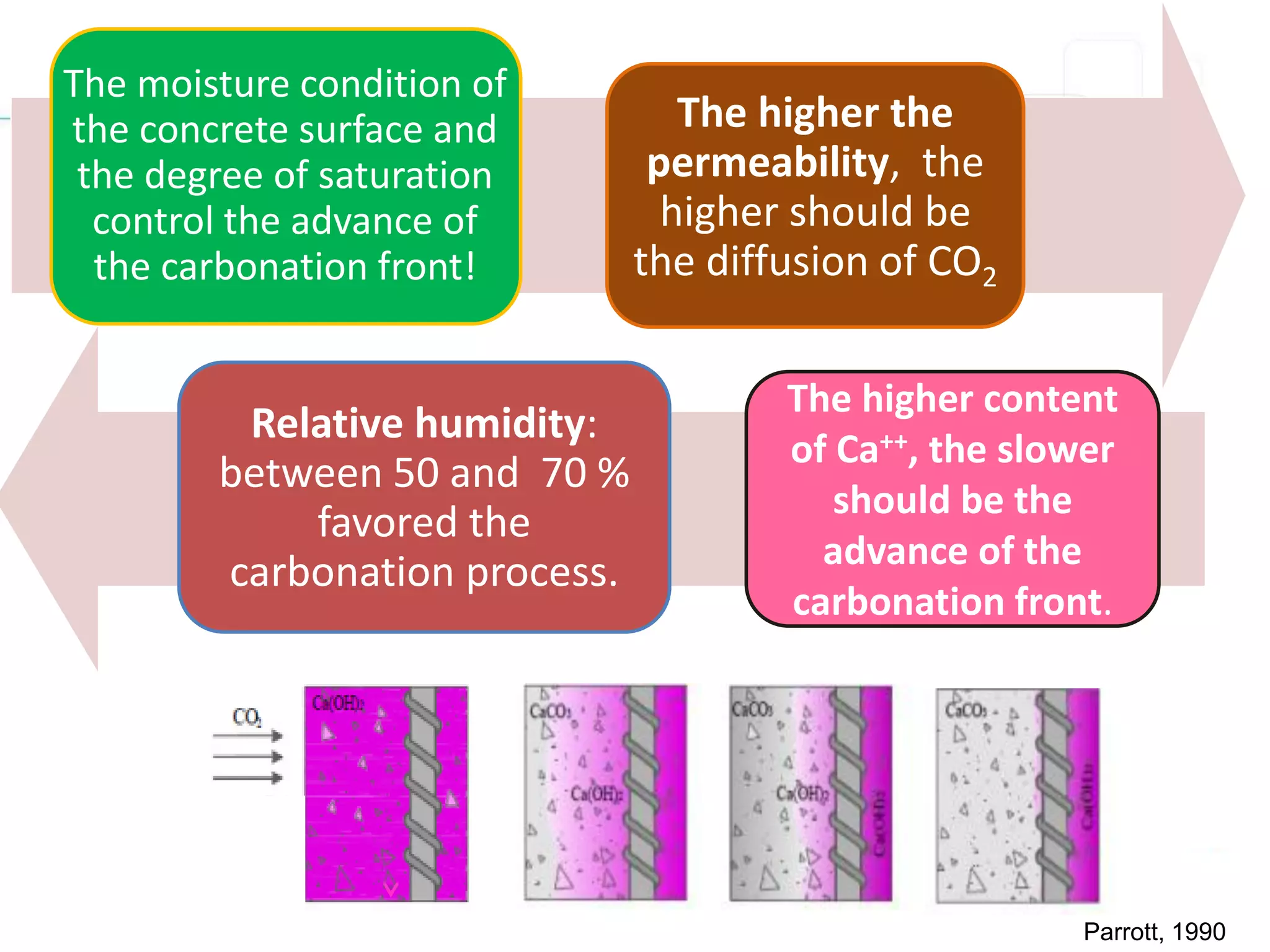

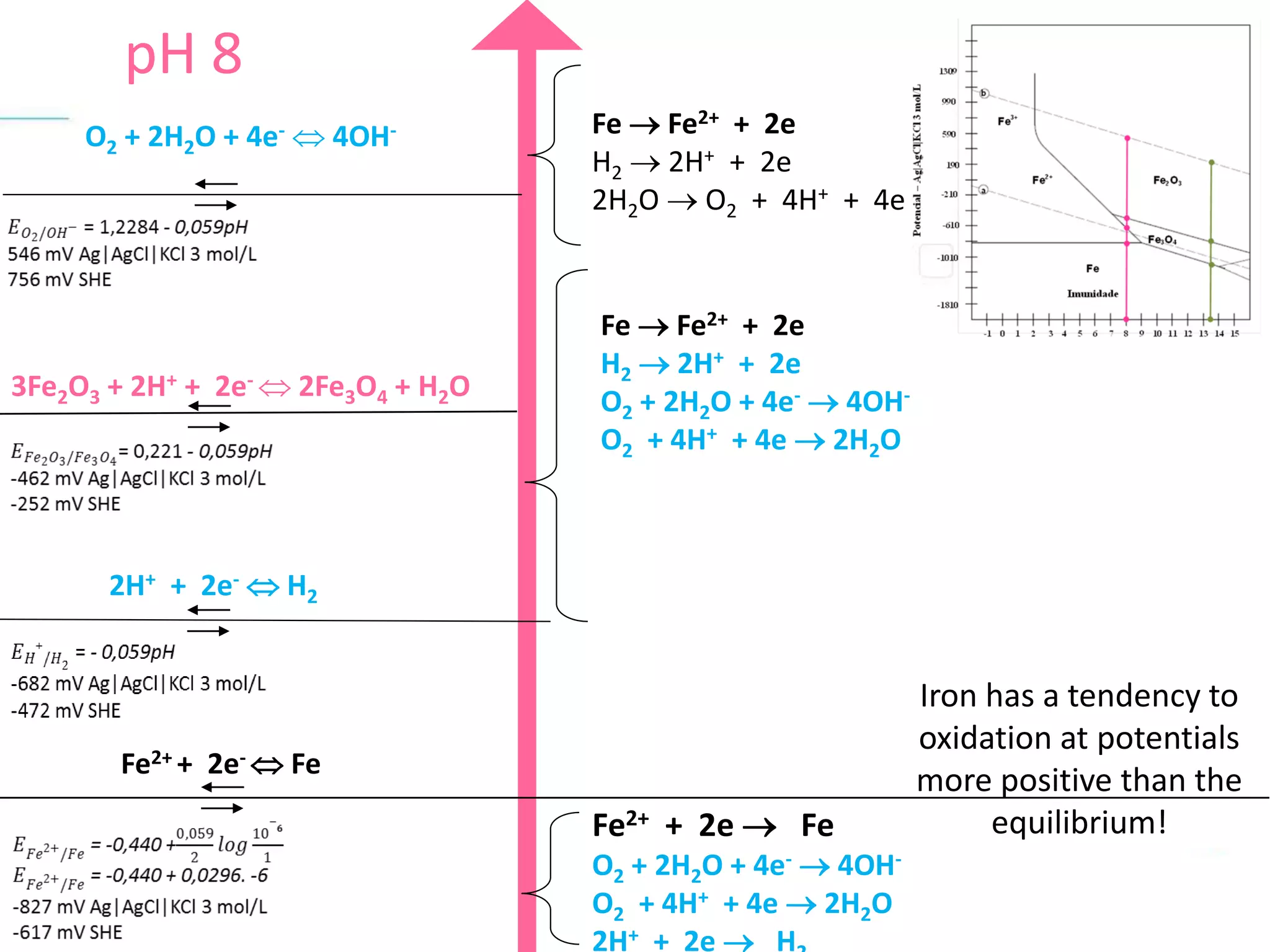

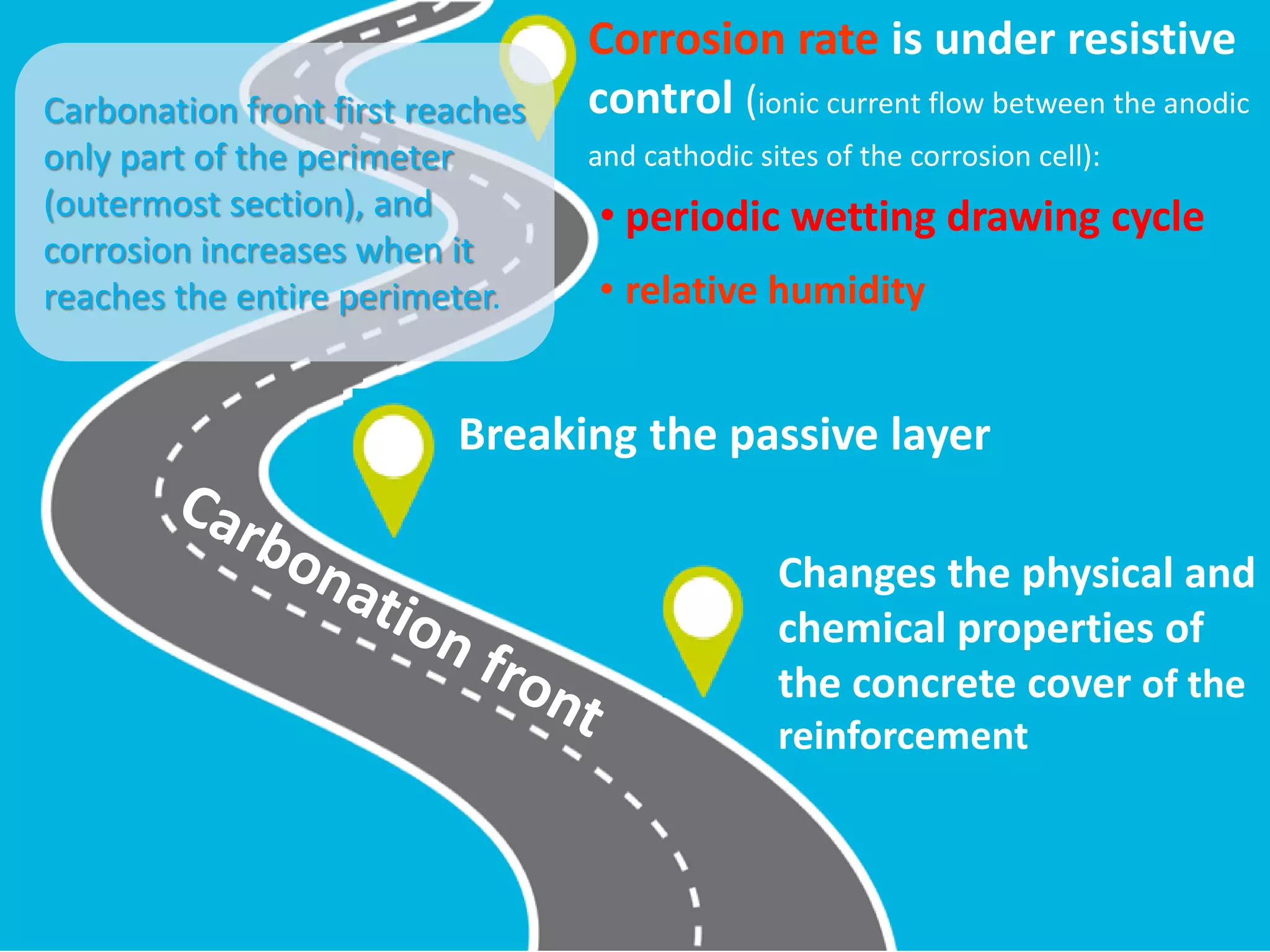

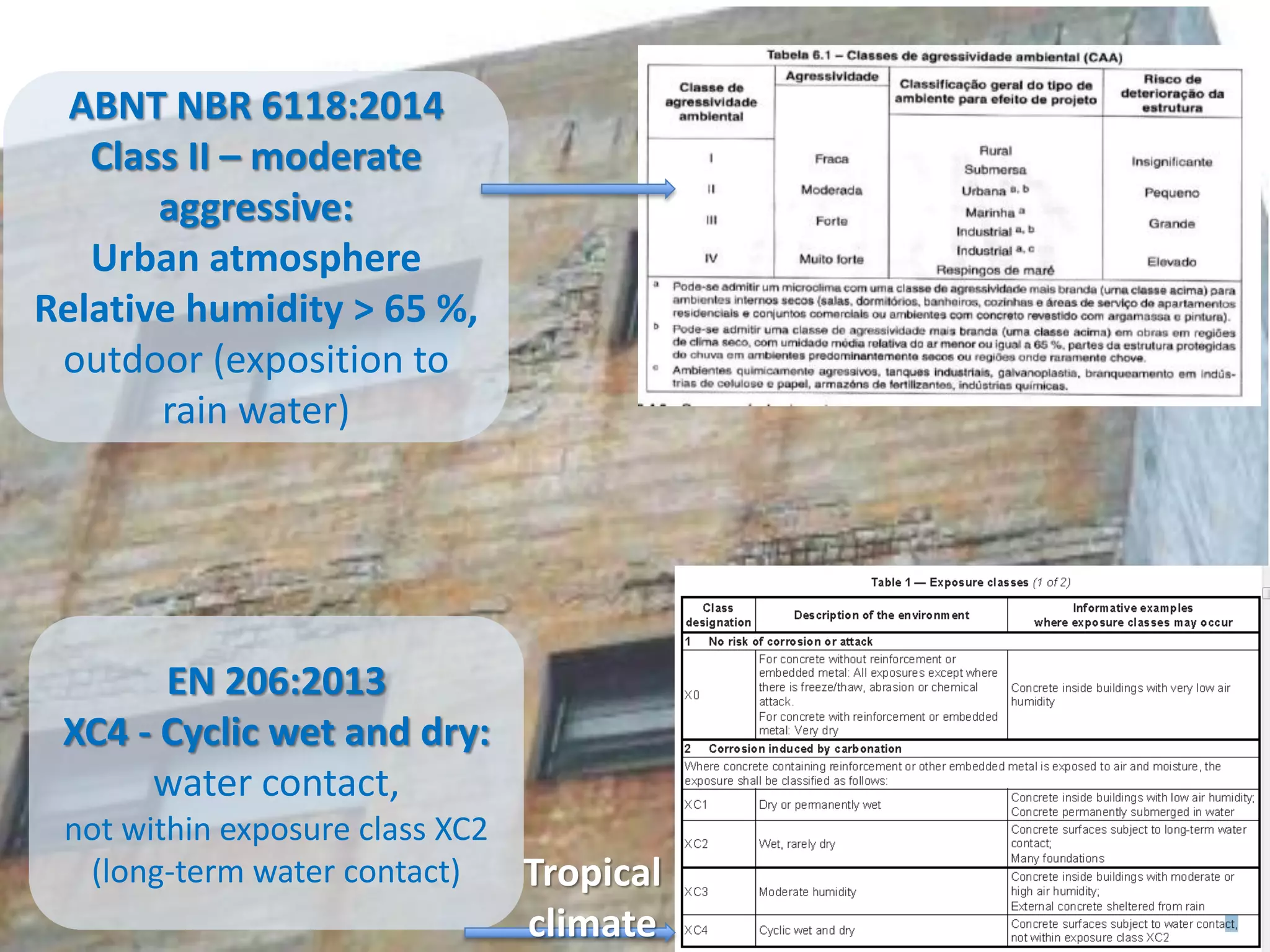

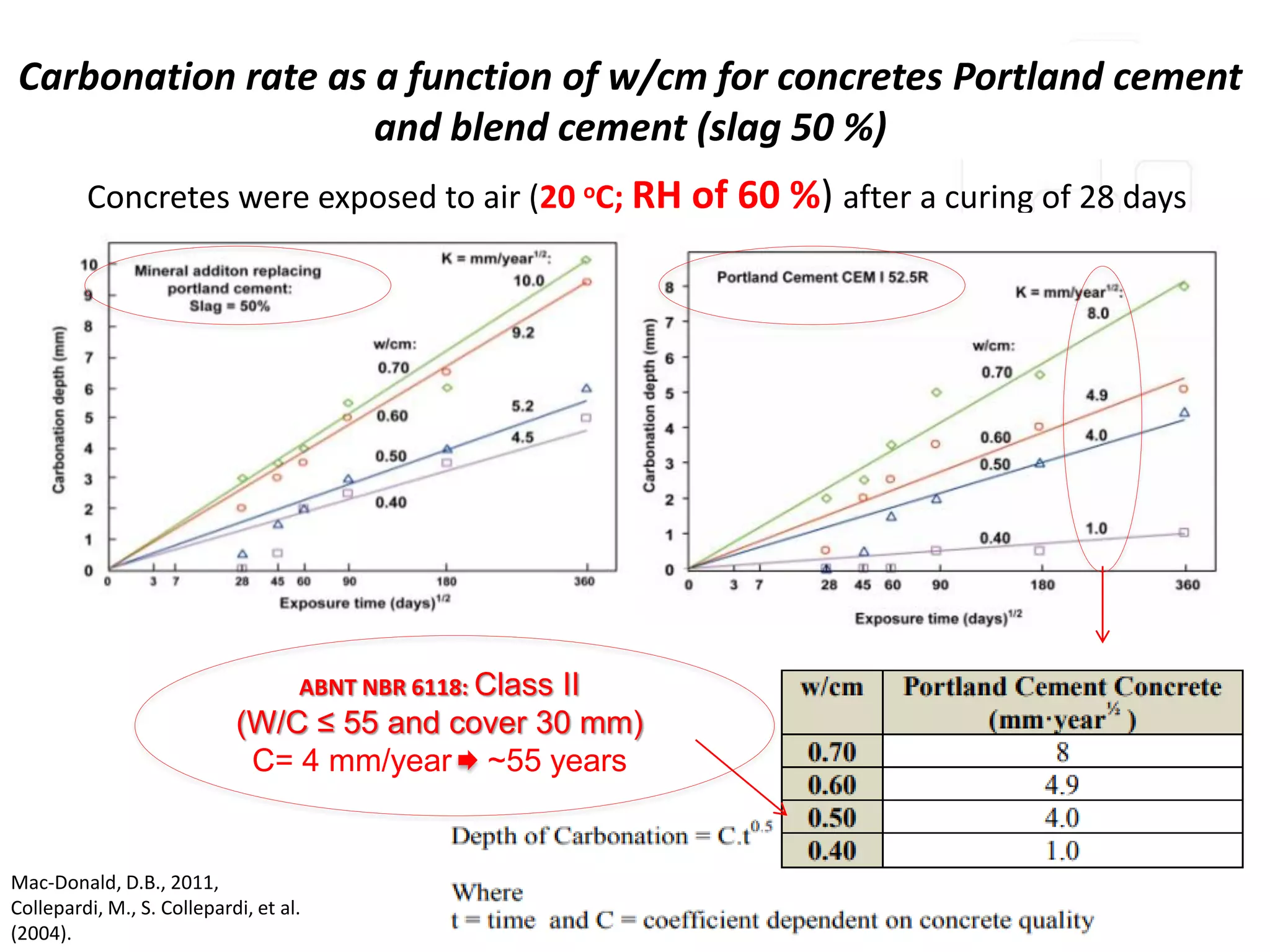

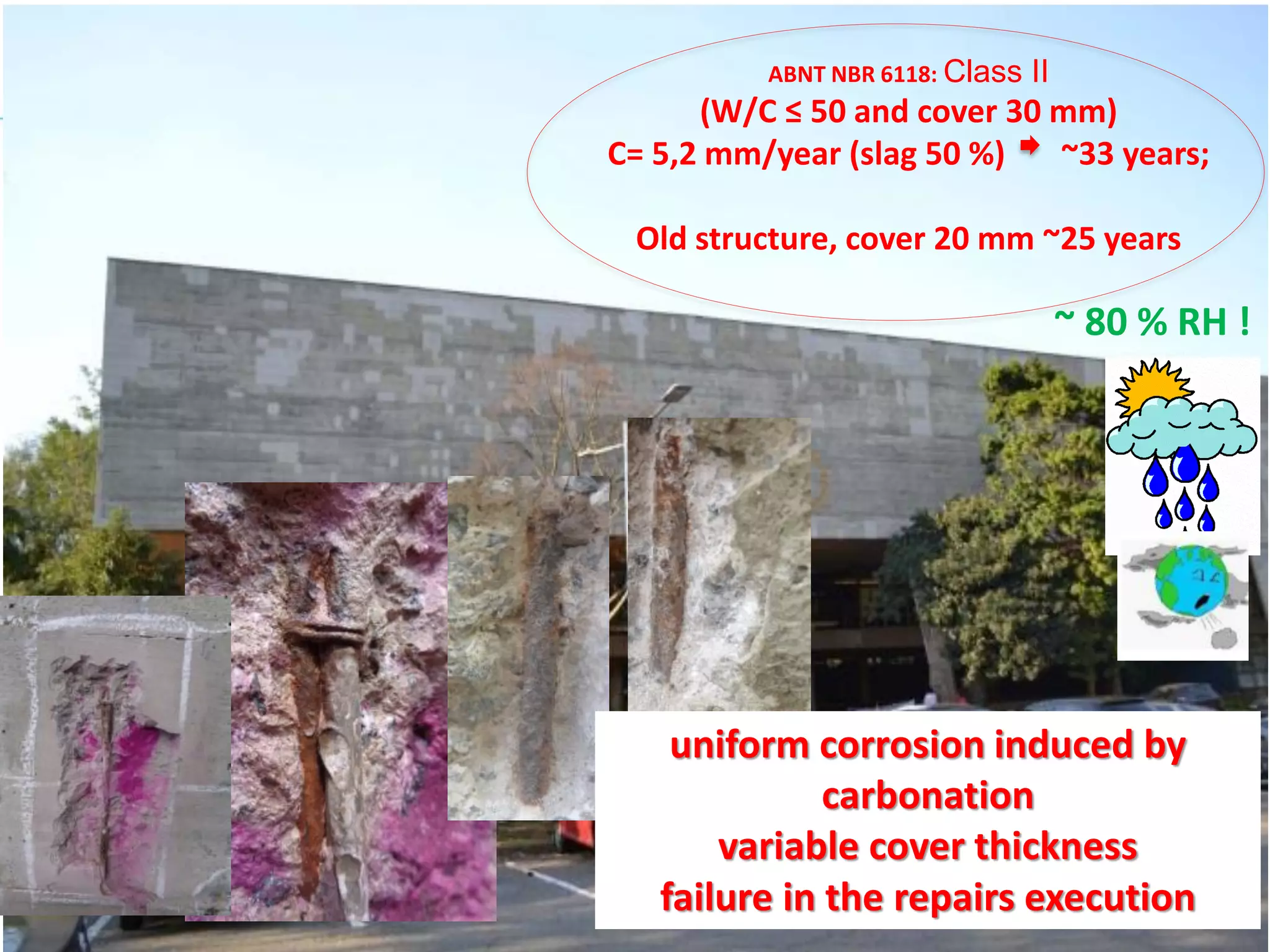

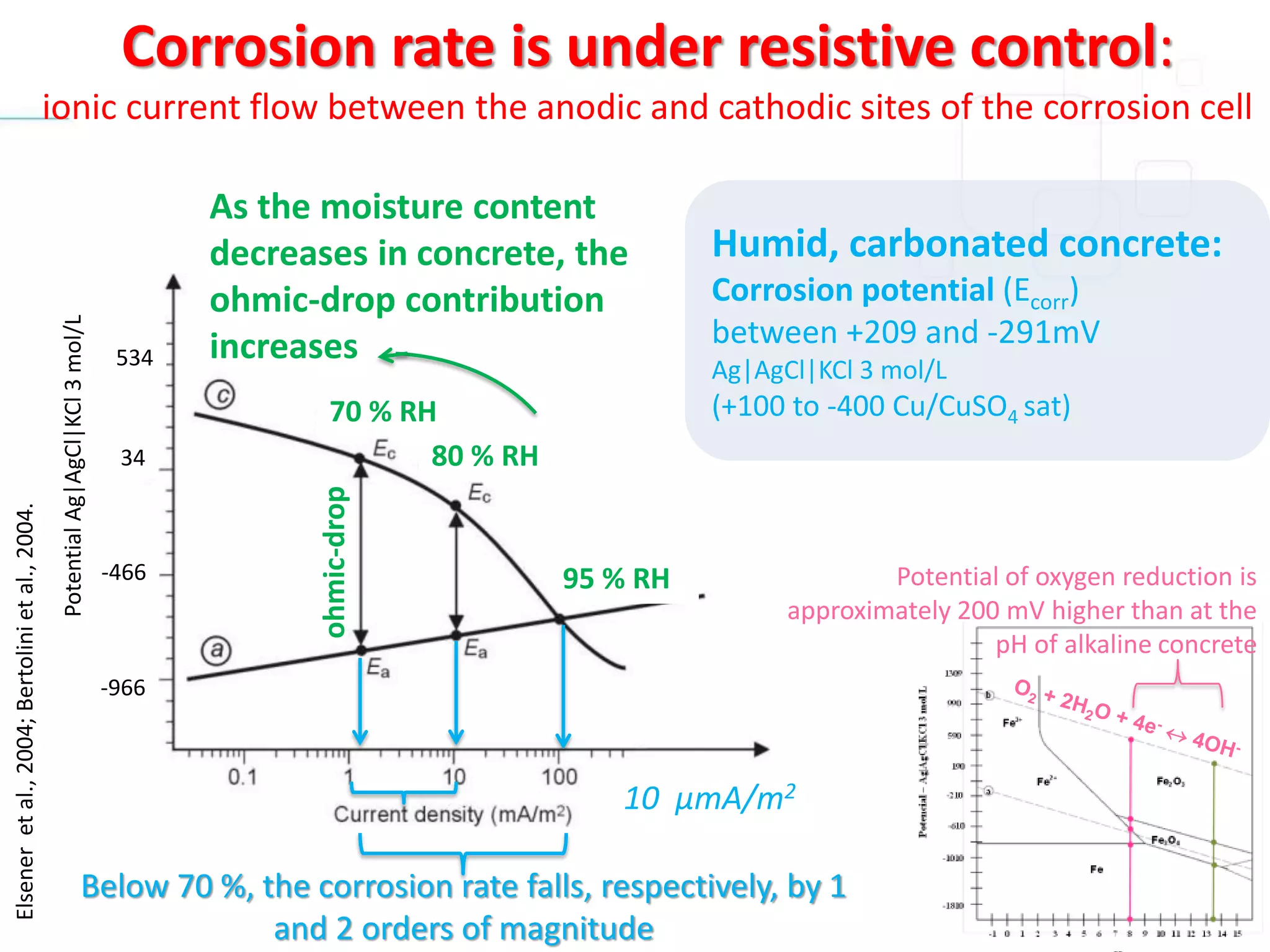

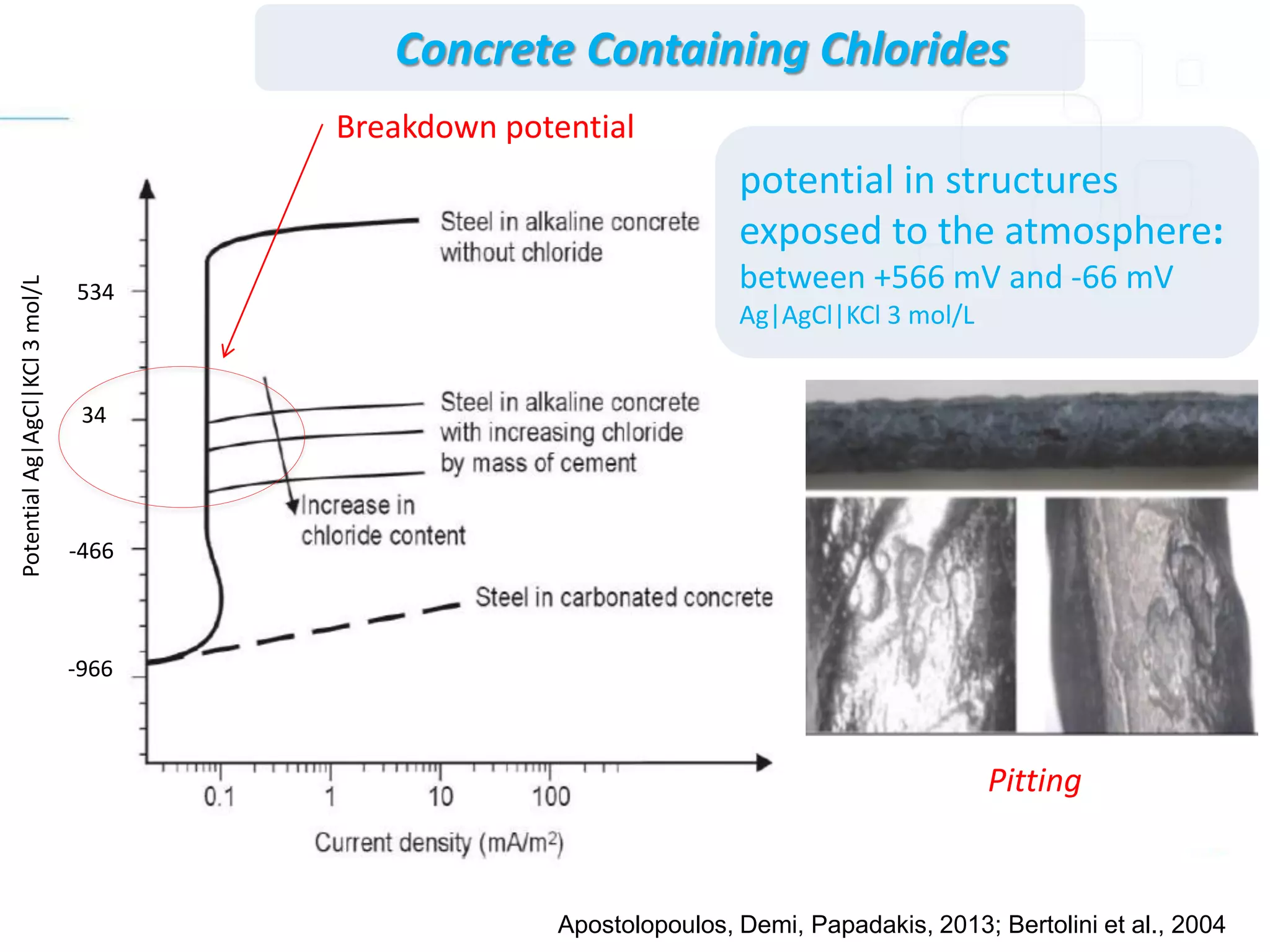

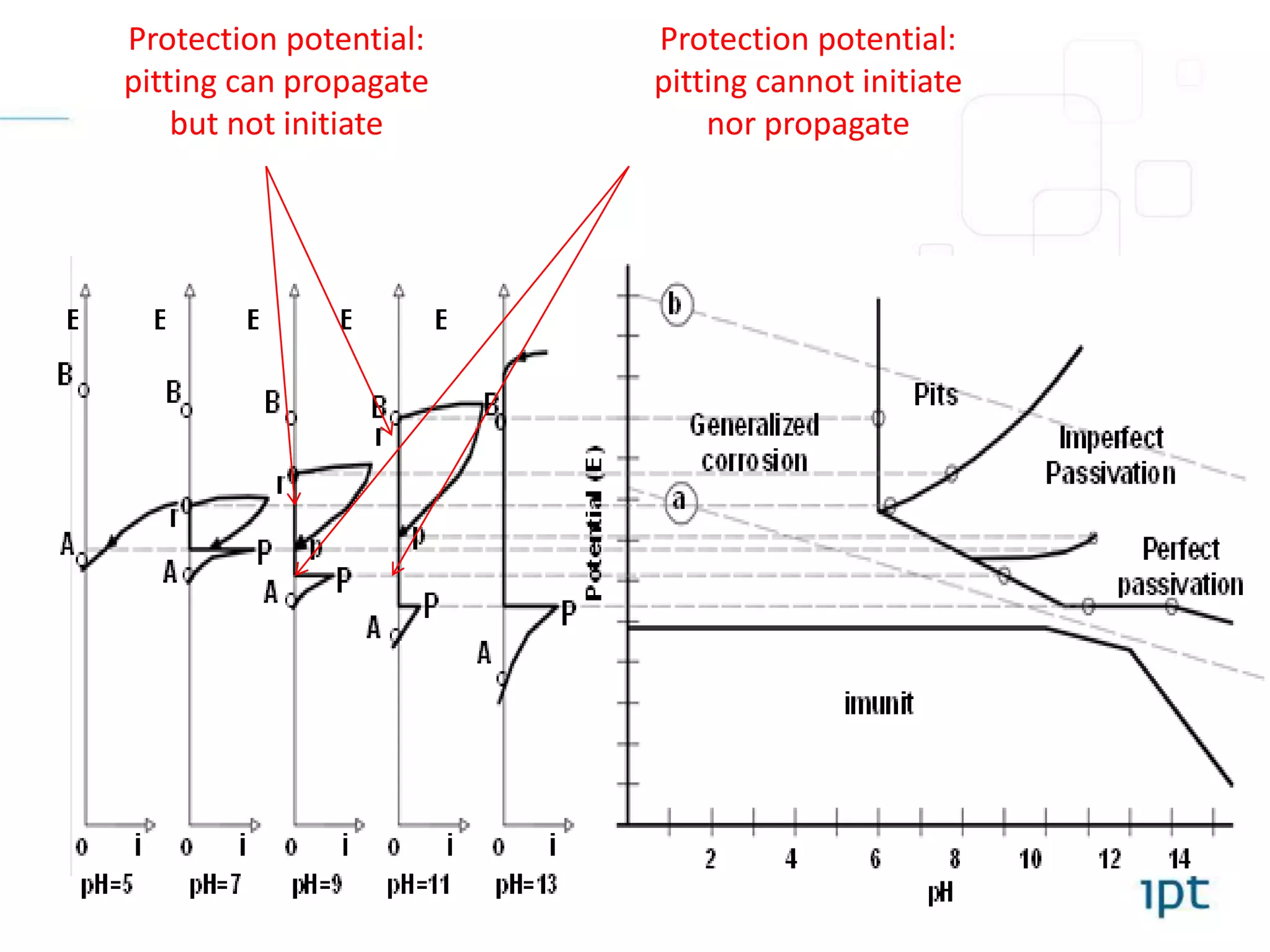

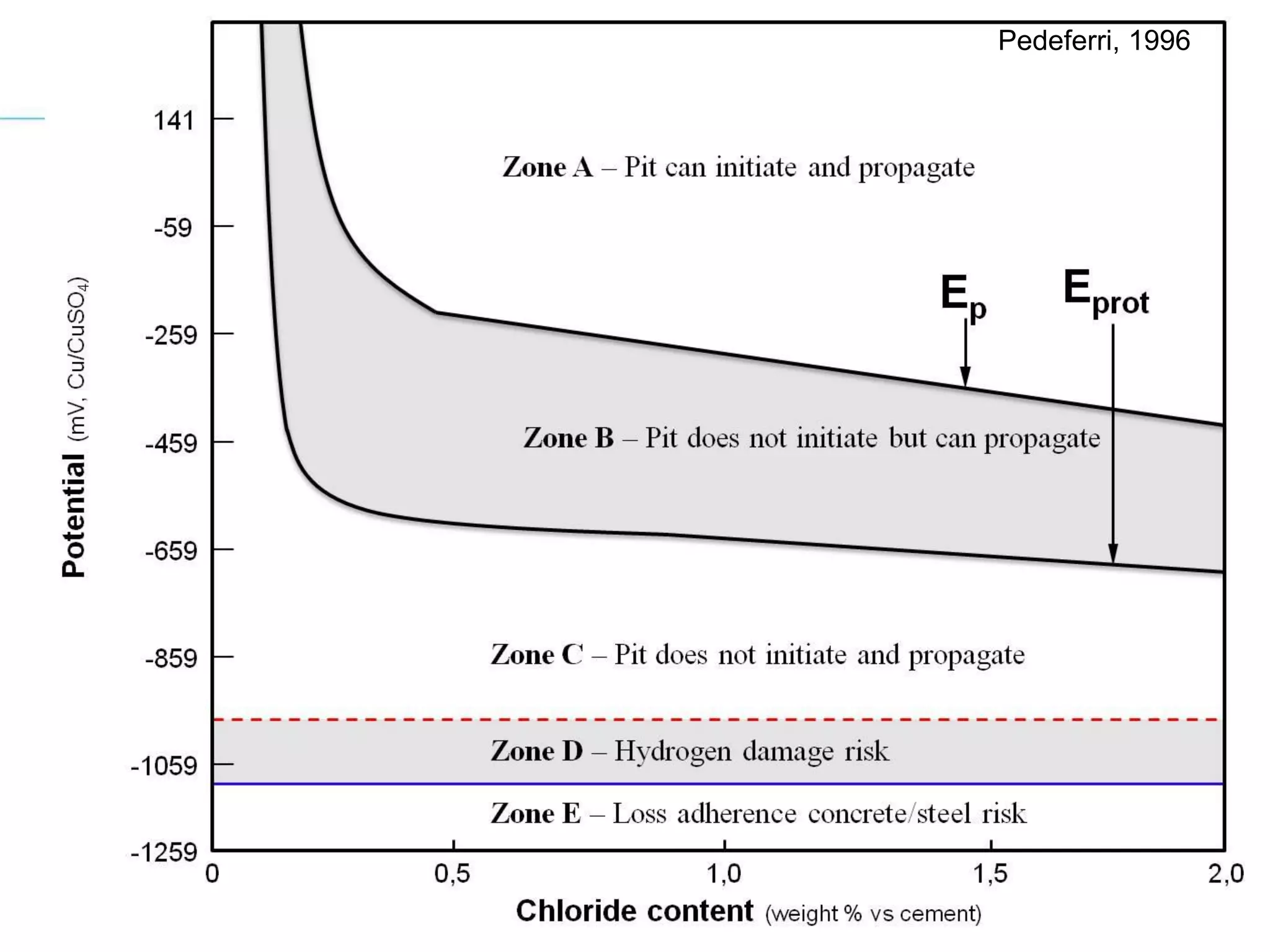

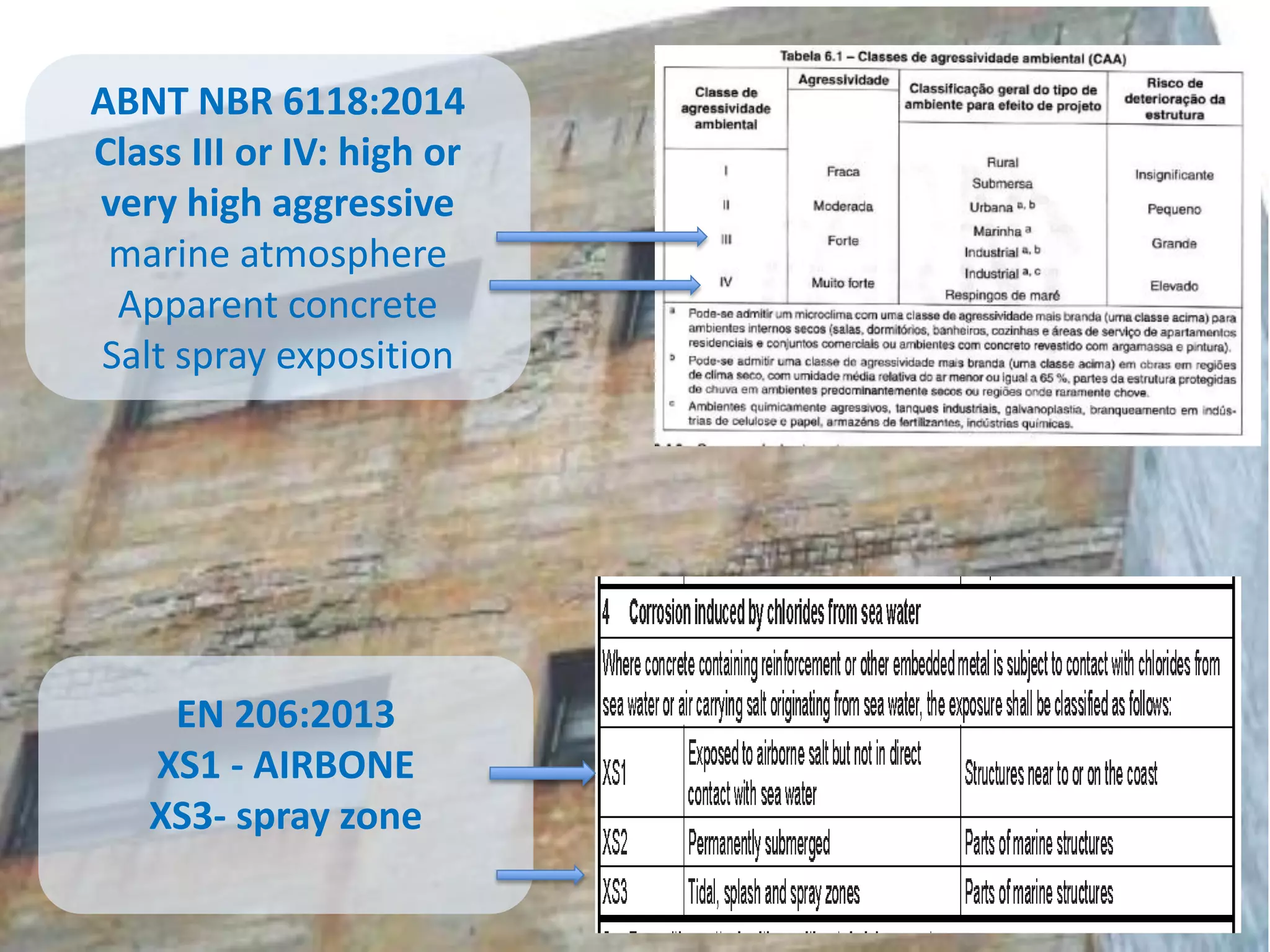

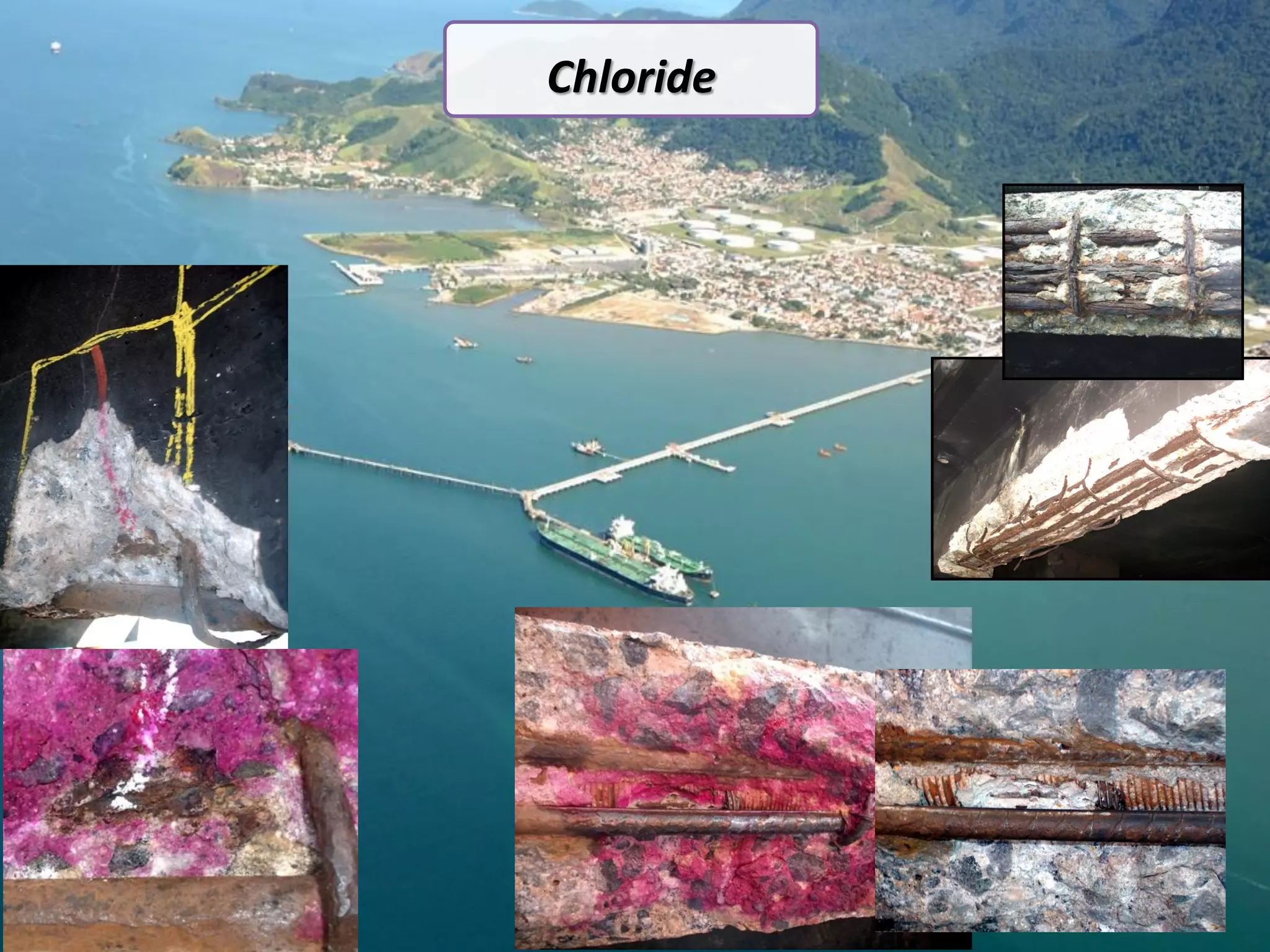

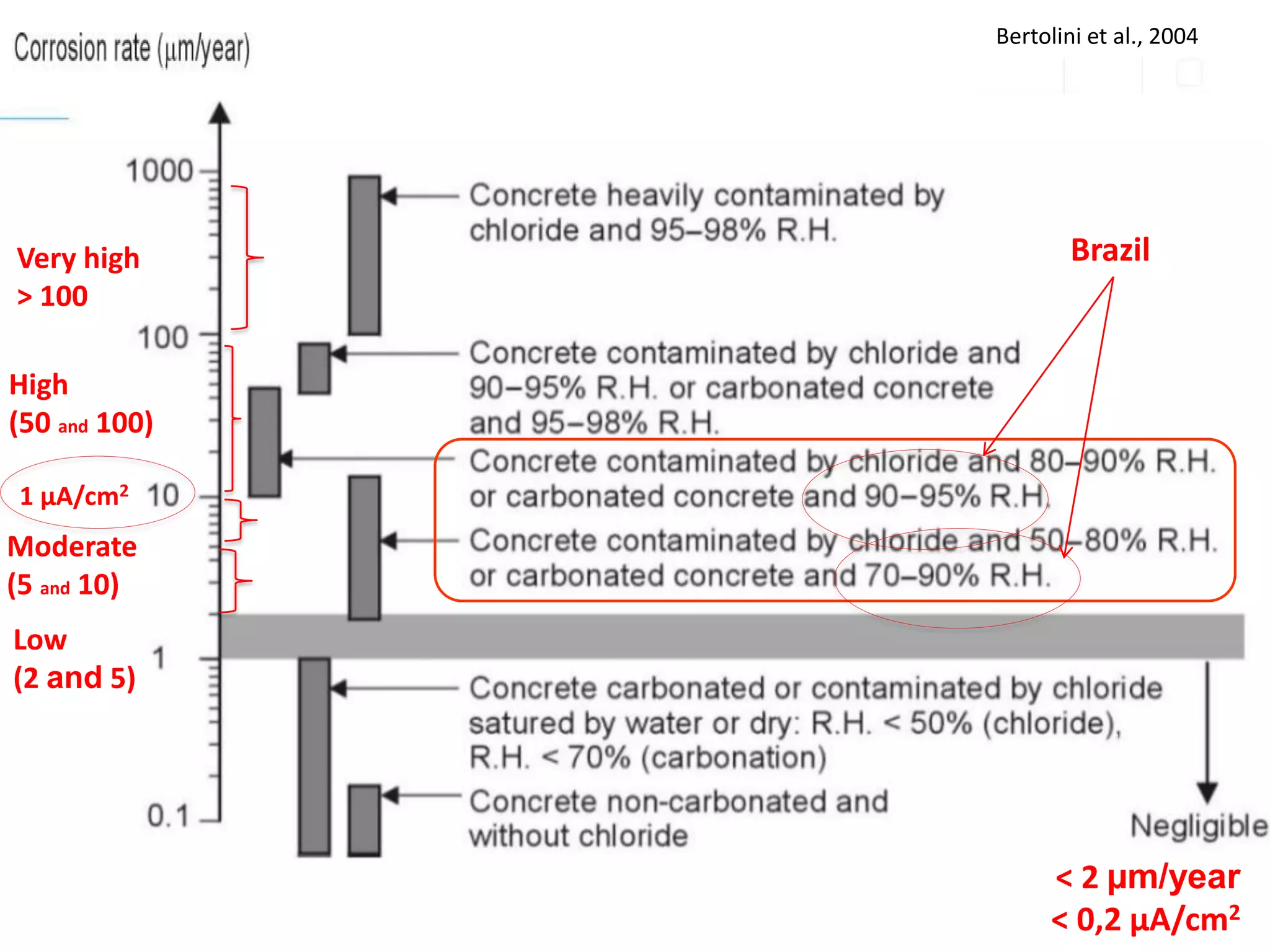

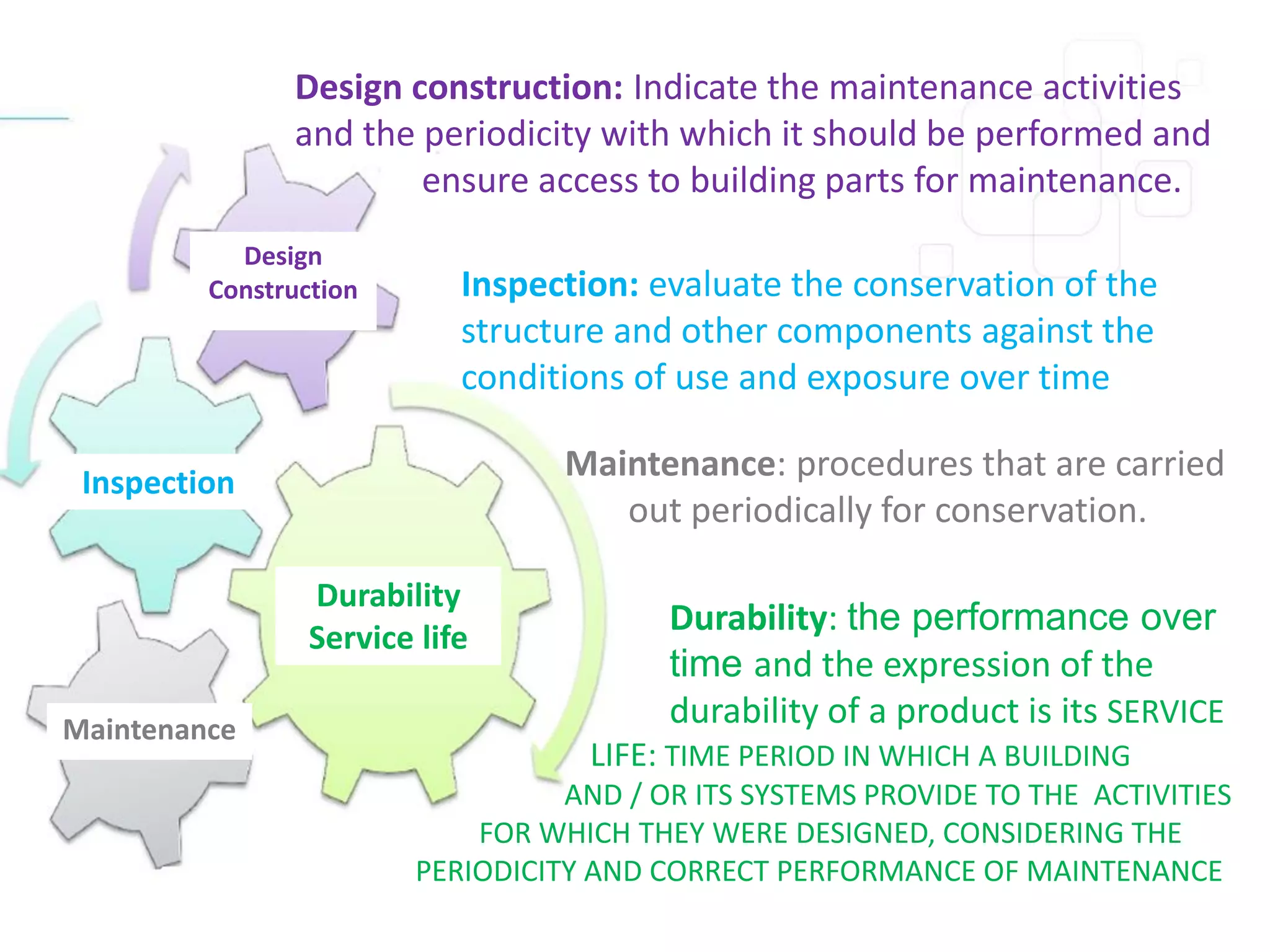

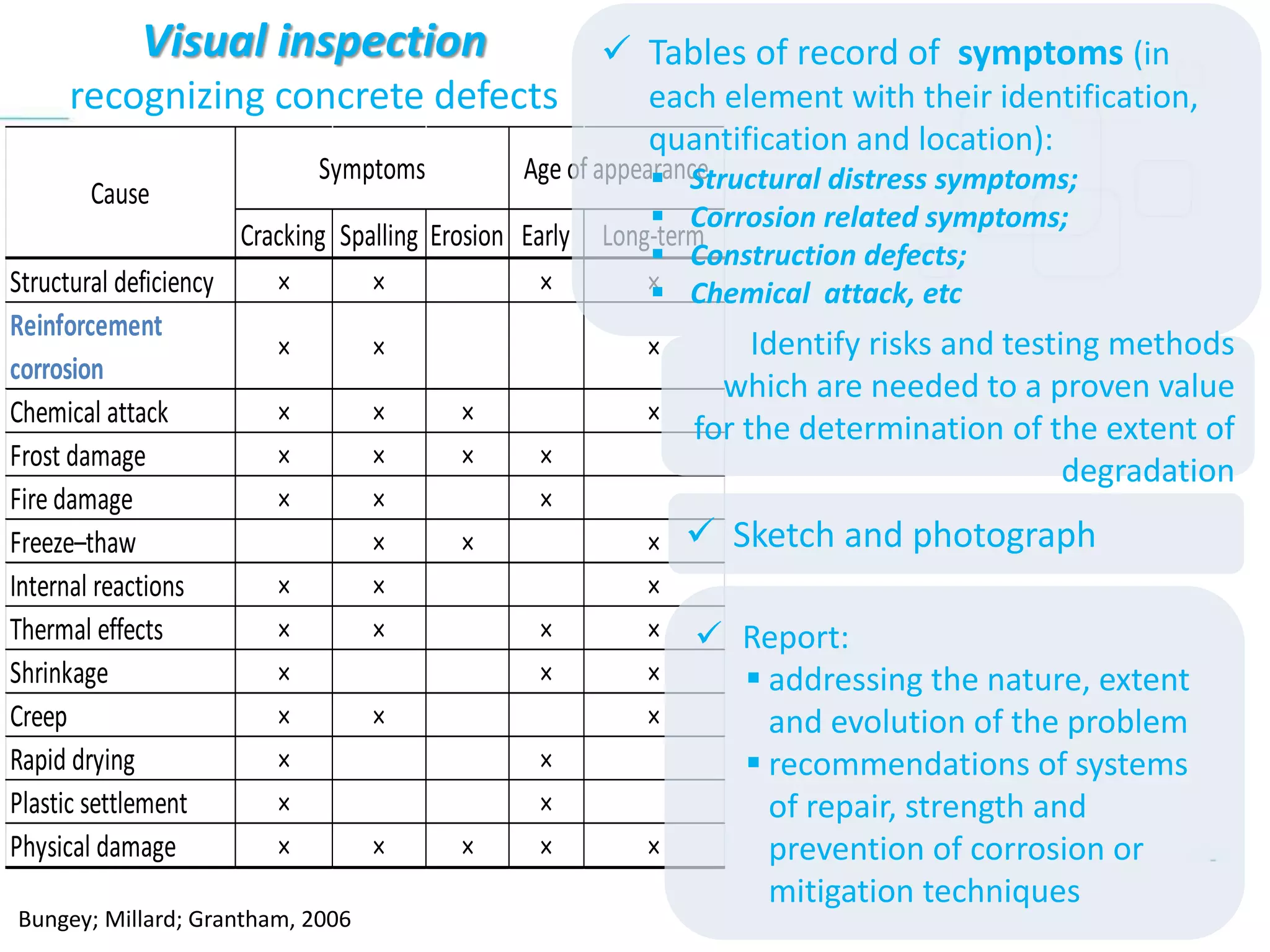

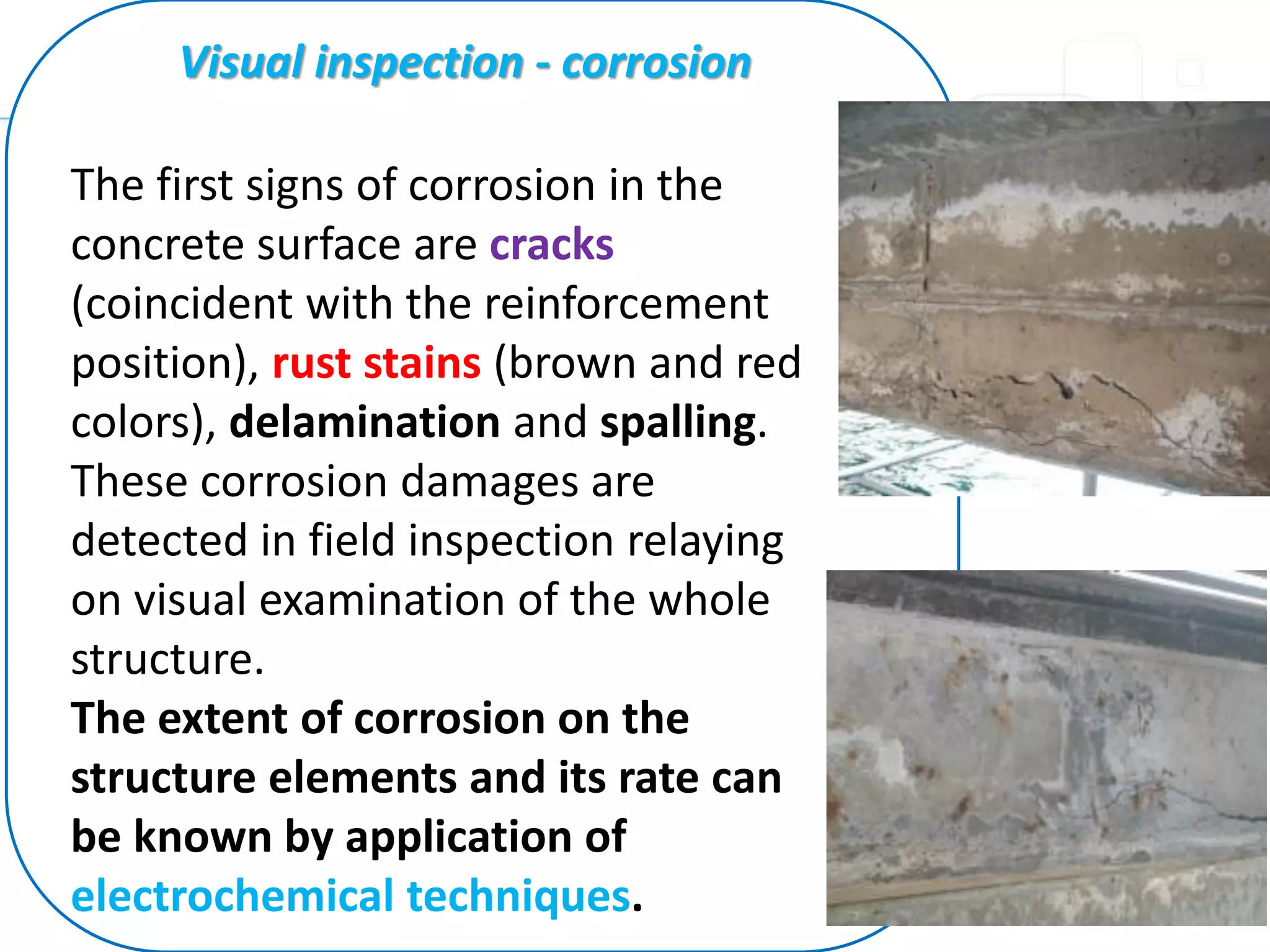

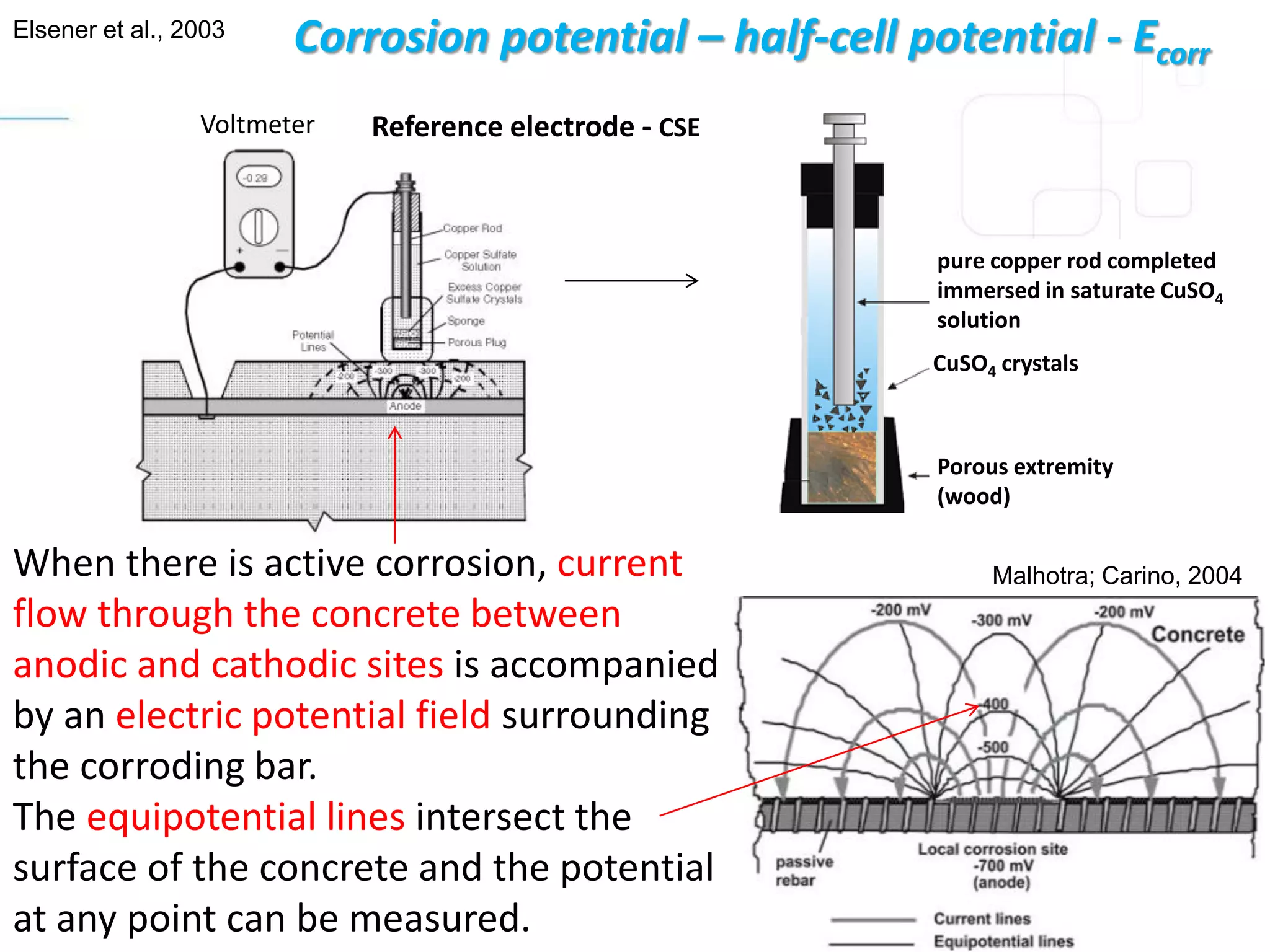

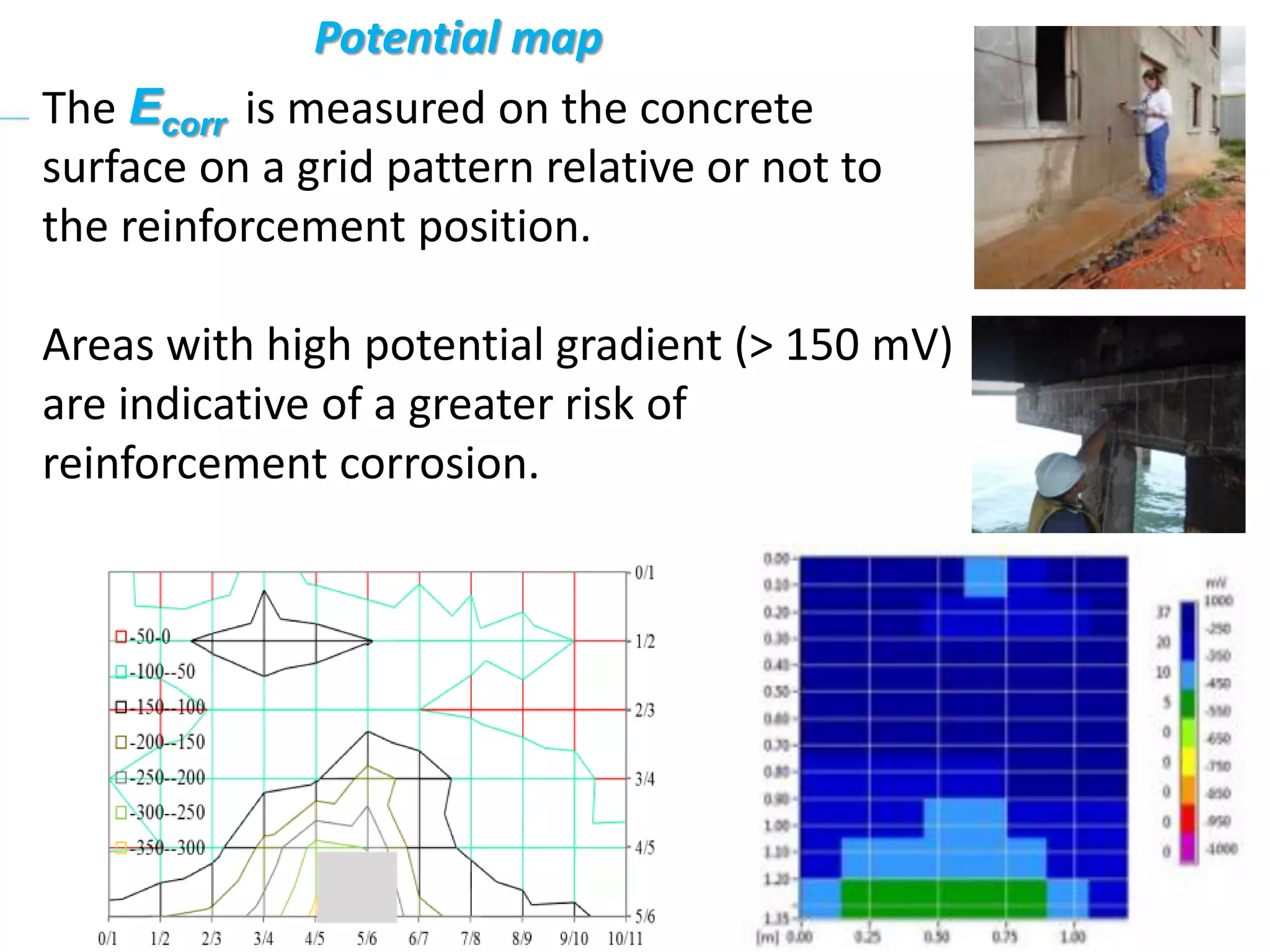

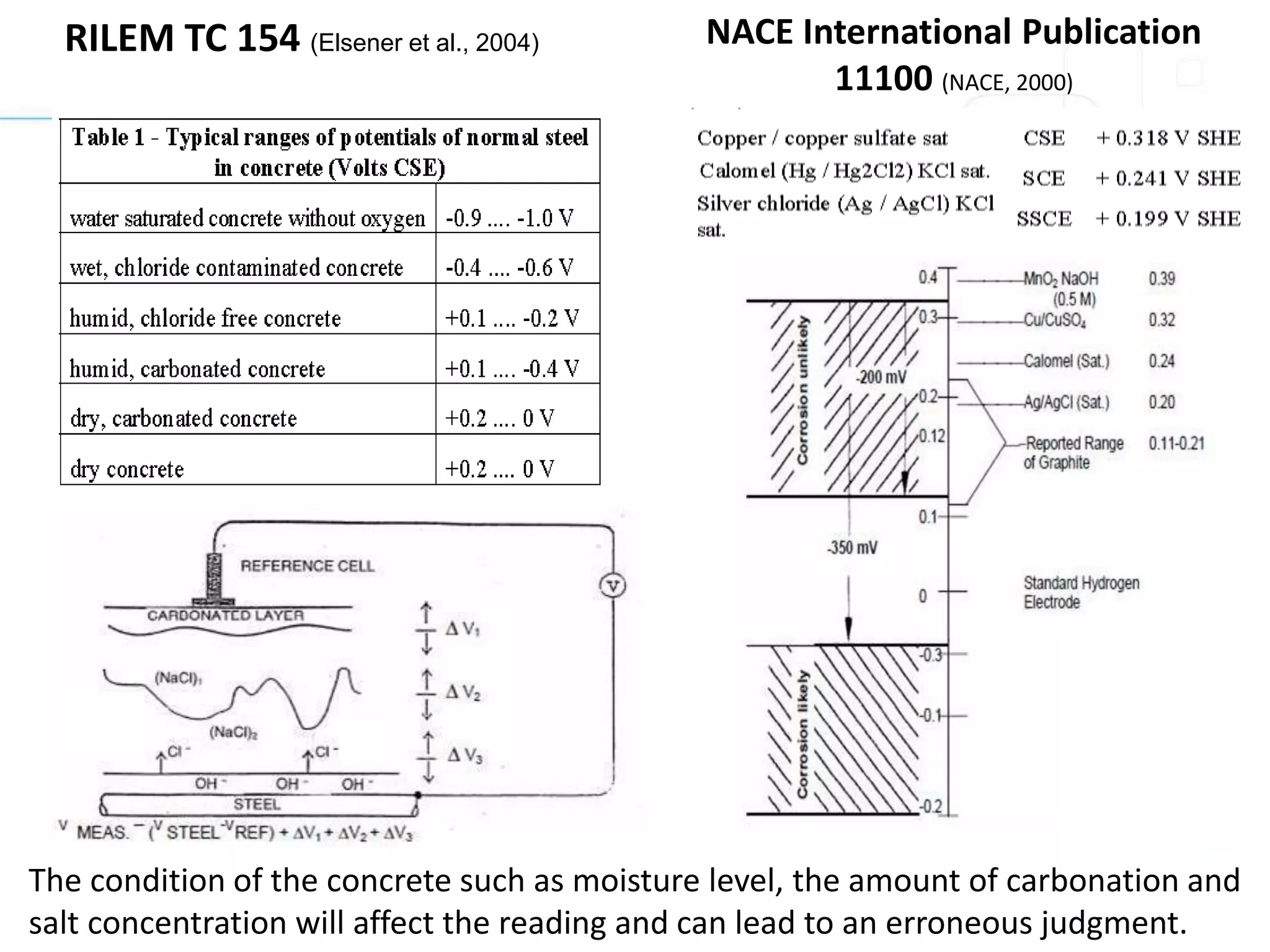

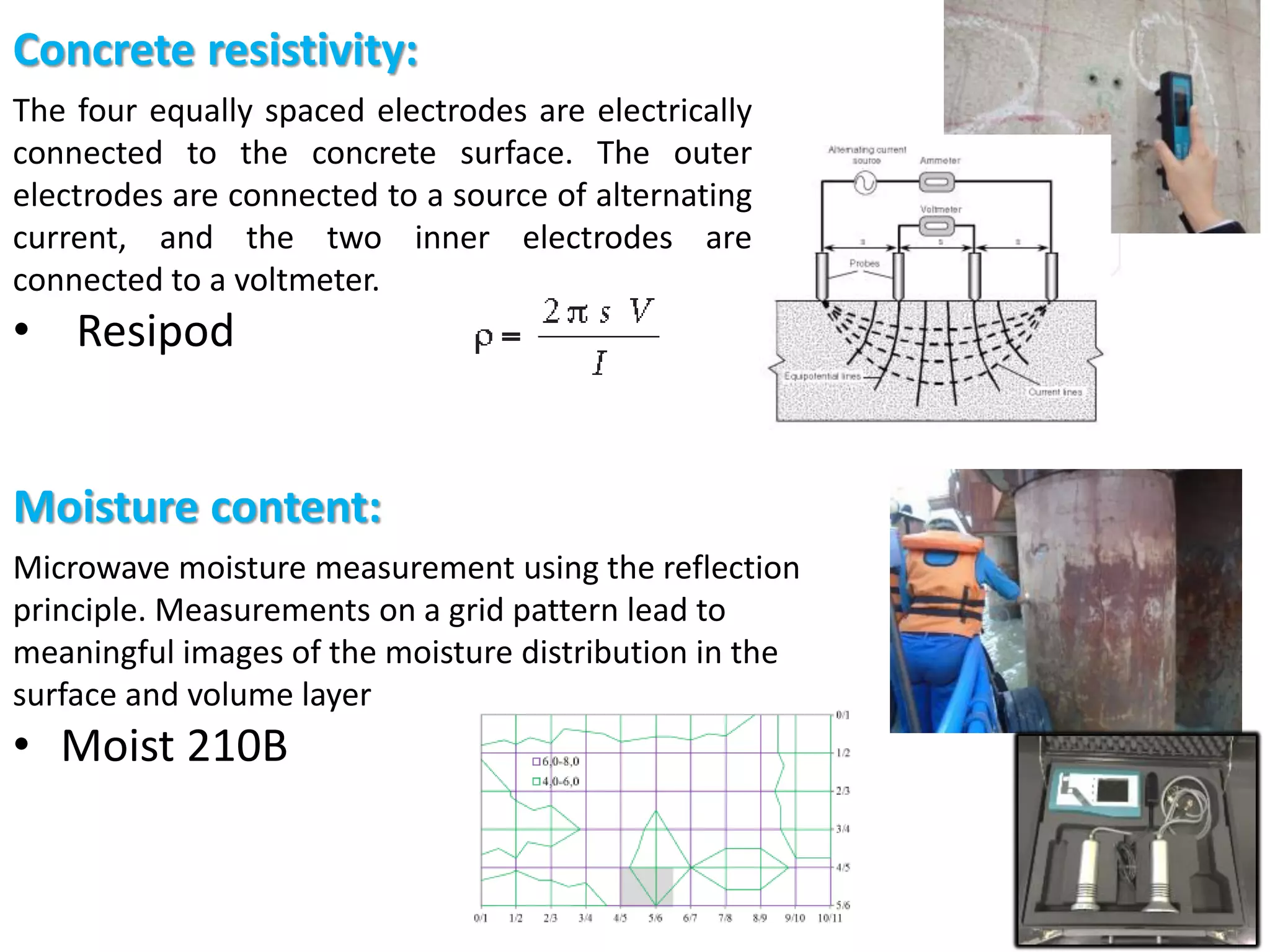

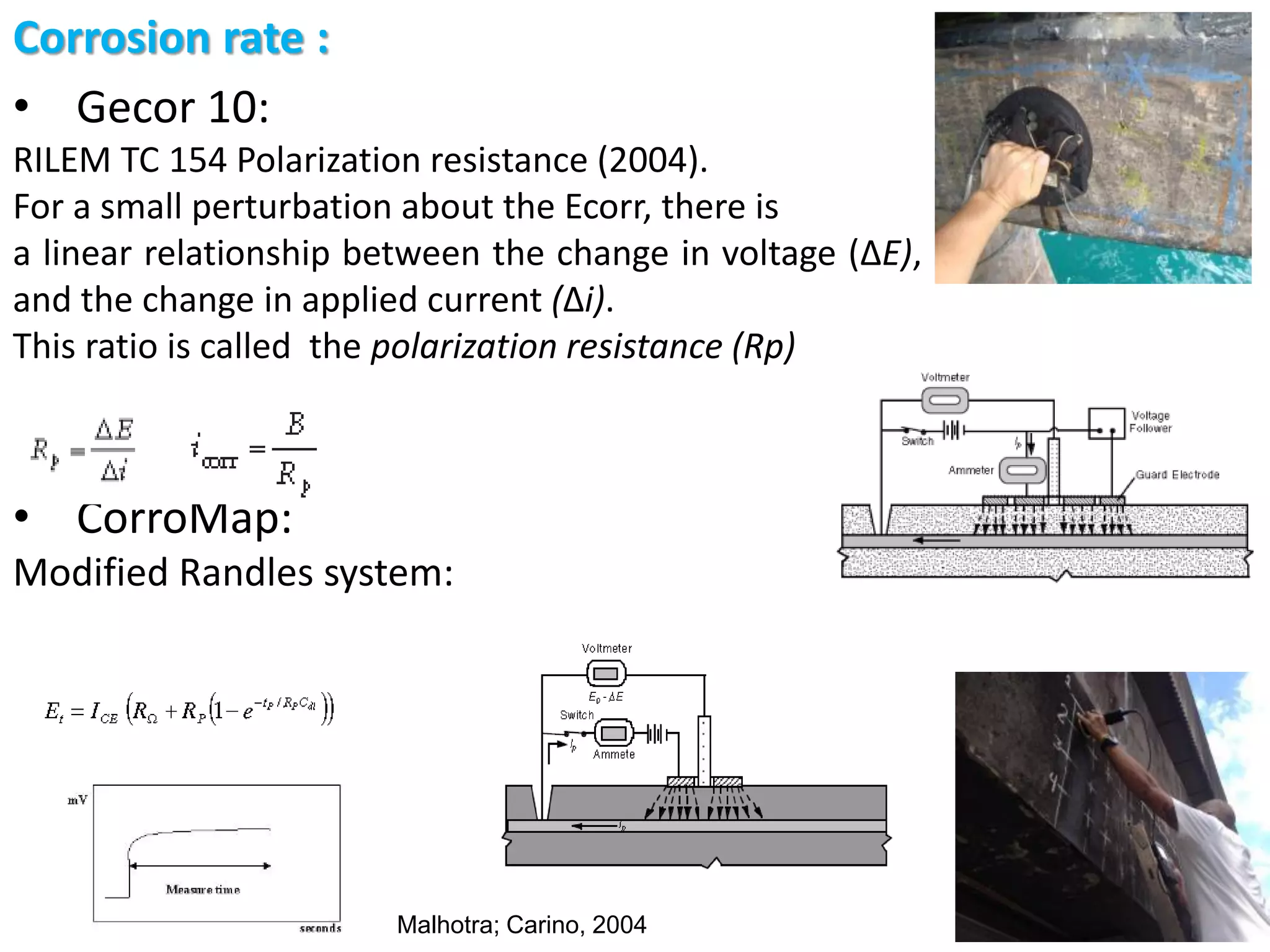

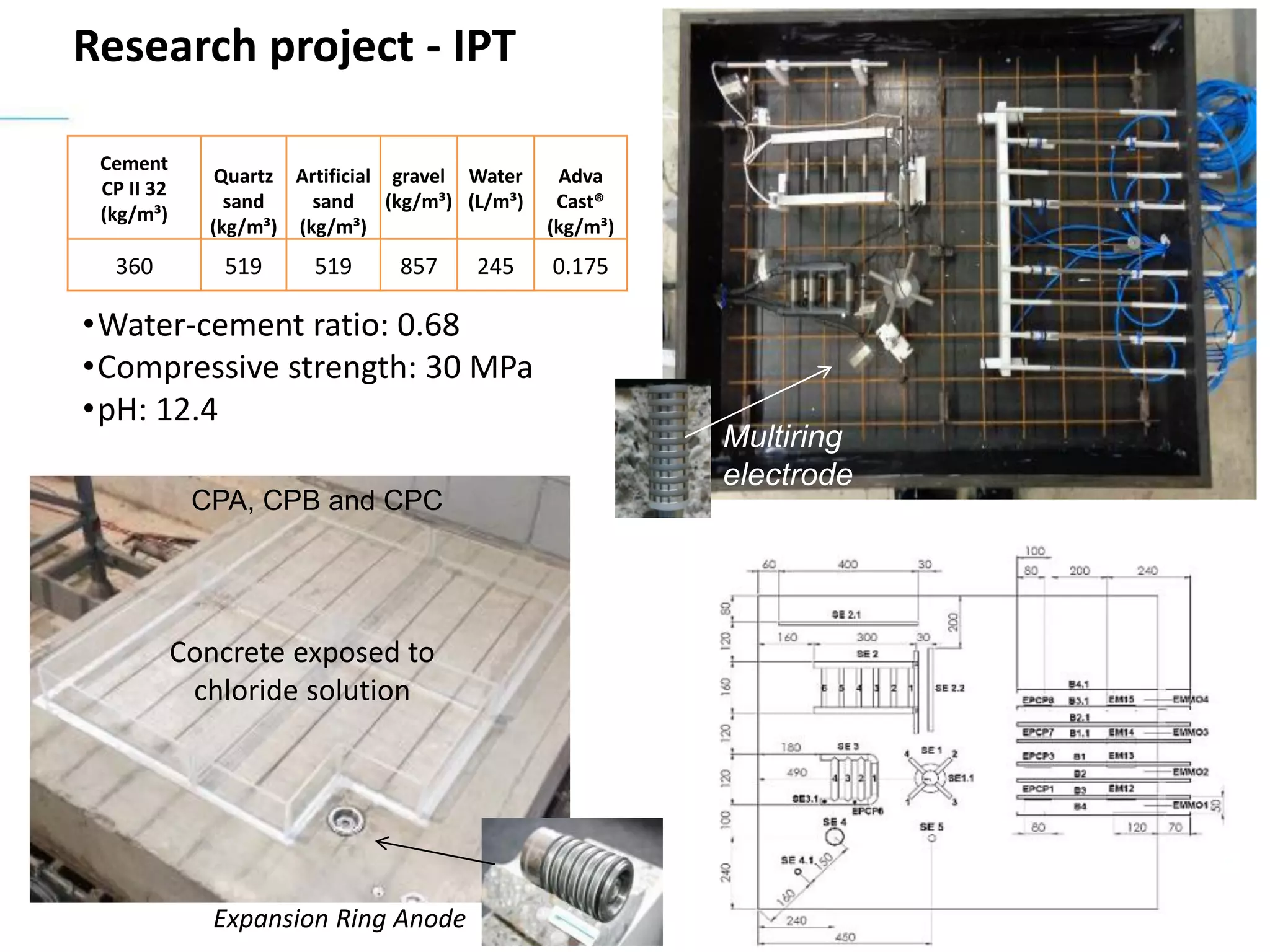

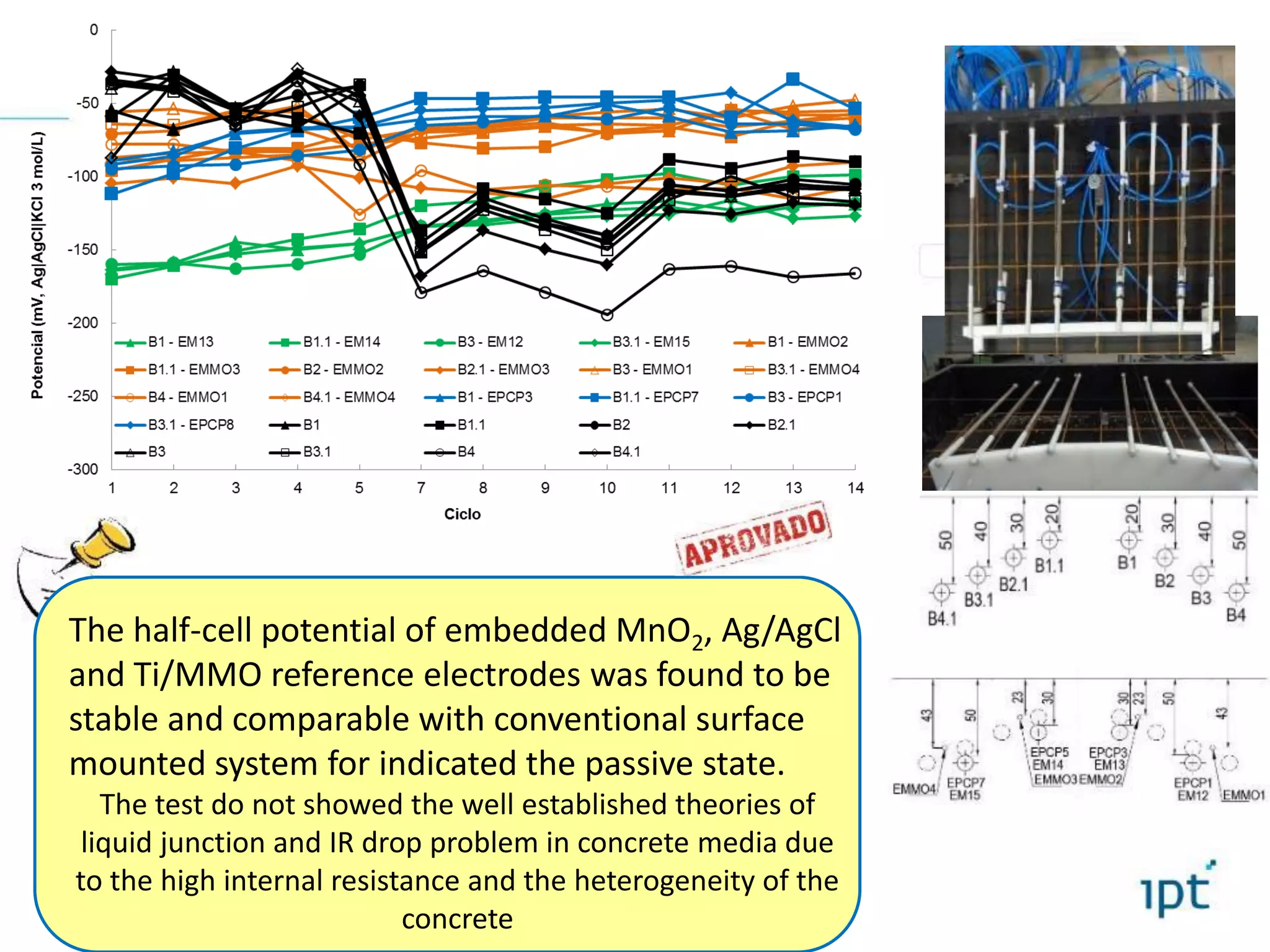

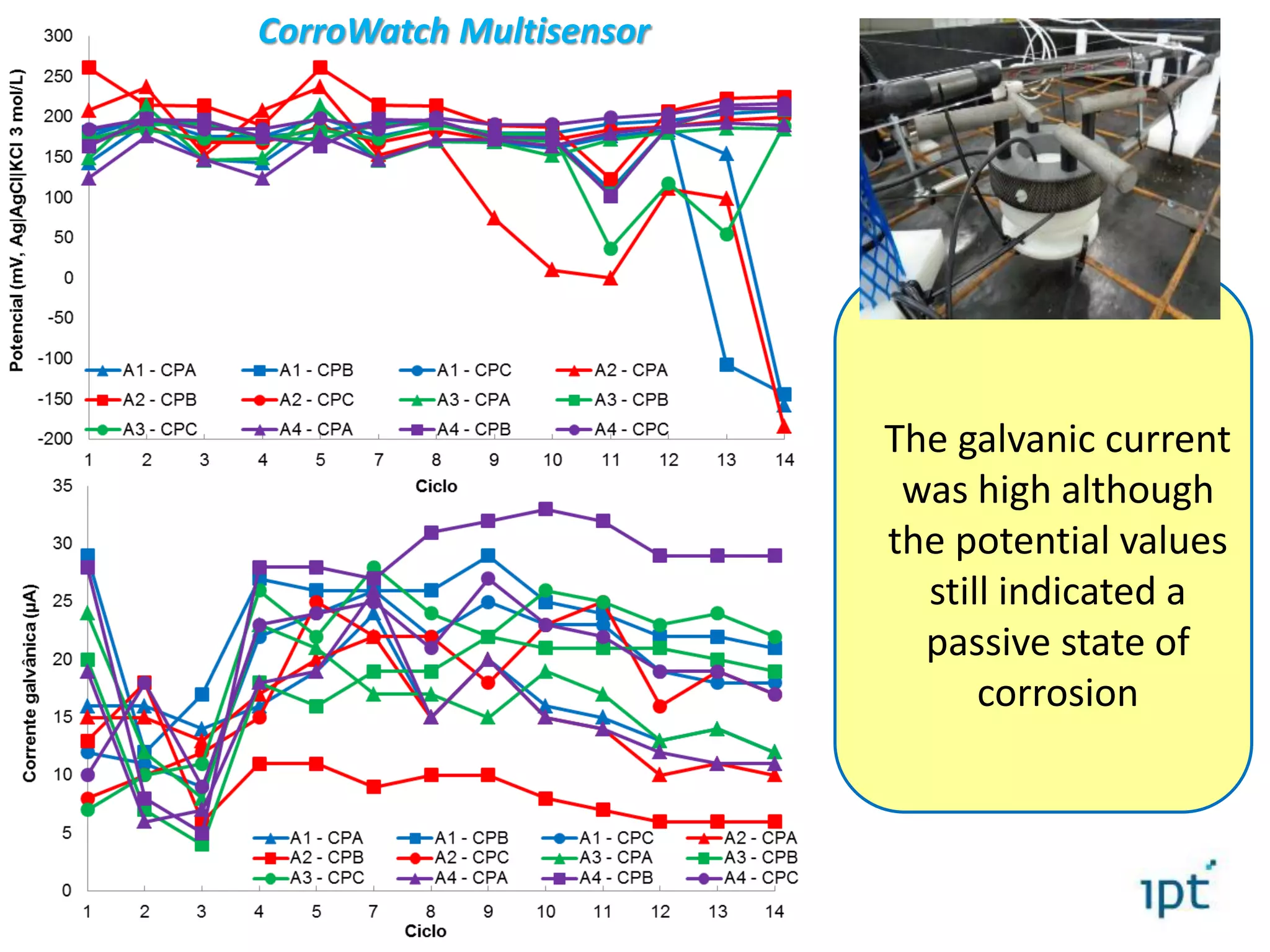

The document discusses the issue of corrosion in reinforced concrete structures, particularly focusing on carbon steel reinforcement in Brazilian urban and marine environments. It covers assessment techniques, monitoring methods, and prevention and rehabilitation strategies to mitigate corrosion risks, emphasizing factors like concrete characteristics and exposure conditions that influence durability. The text also provides insights into the electrochemical processes involved in corrosion and the impact of environmental factors, such as chloride ions and moisture content, on corrosion rates.