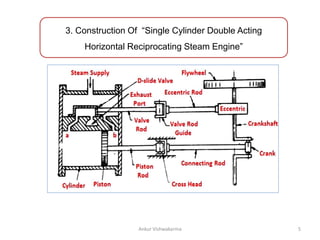

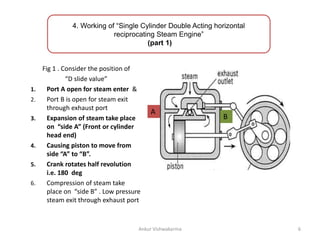

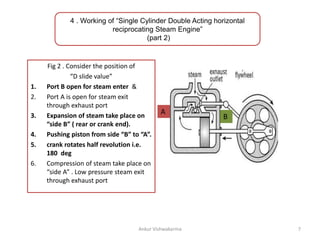

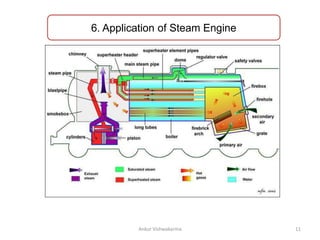

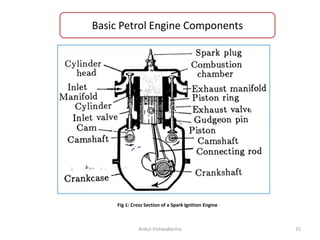

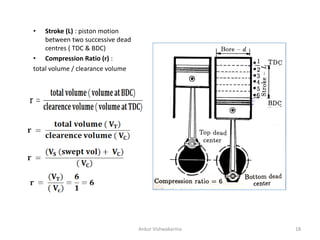

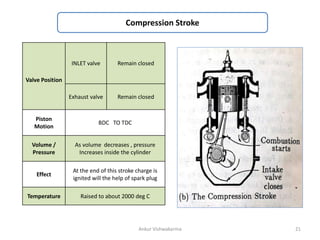

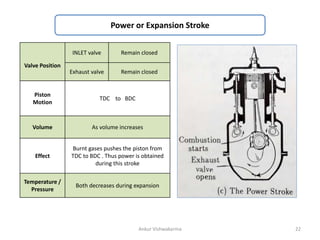

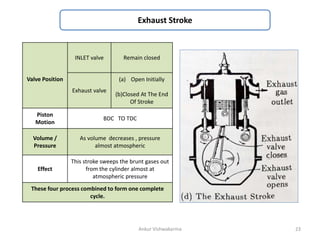

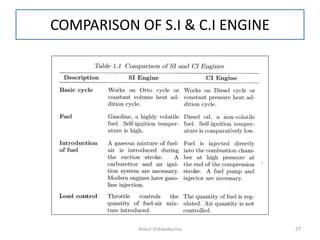

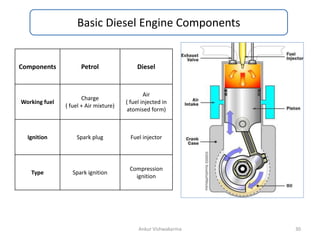

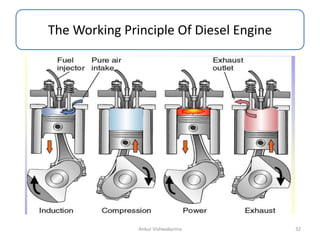

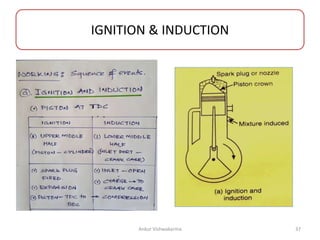

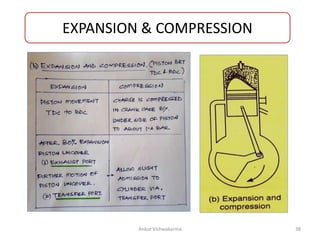

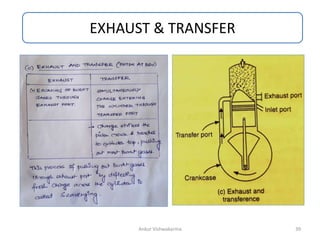

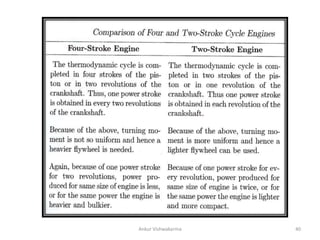

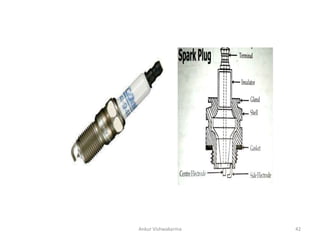

This document discusses different types of reciprocating machines, including steam engines, petrol engines, and diesel engines. It provides details on the construction and working of a single cylinder double acting horizontal reciprocating steam engine. It also explains the Rankine cycle and applications of steam engines. Additionally, it covers the basic components, working, and thermodynamic cycles of petrol and diesel engines, including comparisons between their operations and cycles. Two-stroke engines are also introduced.