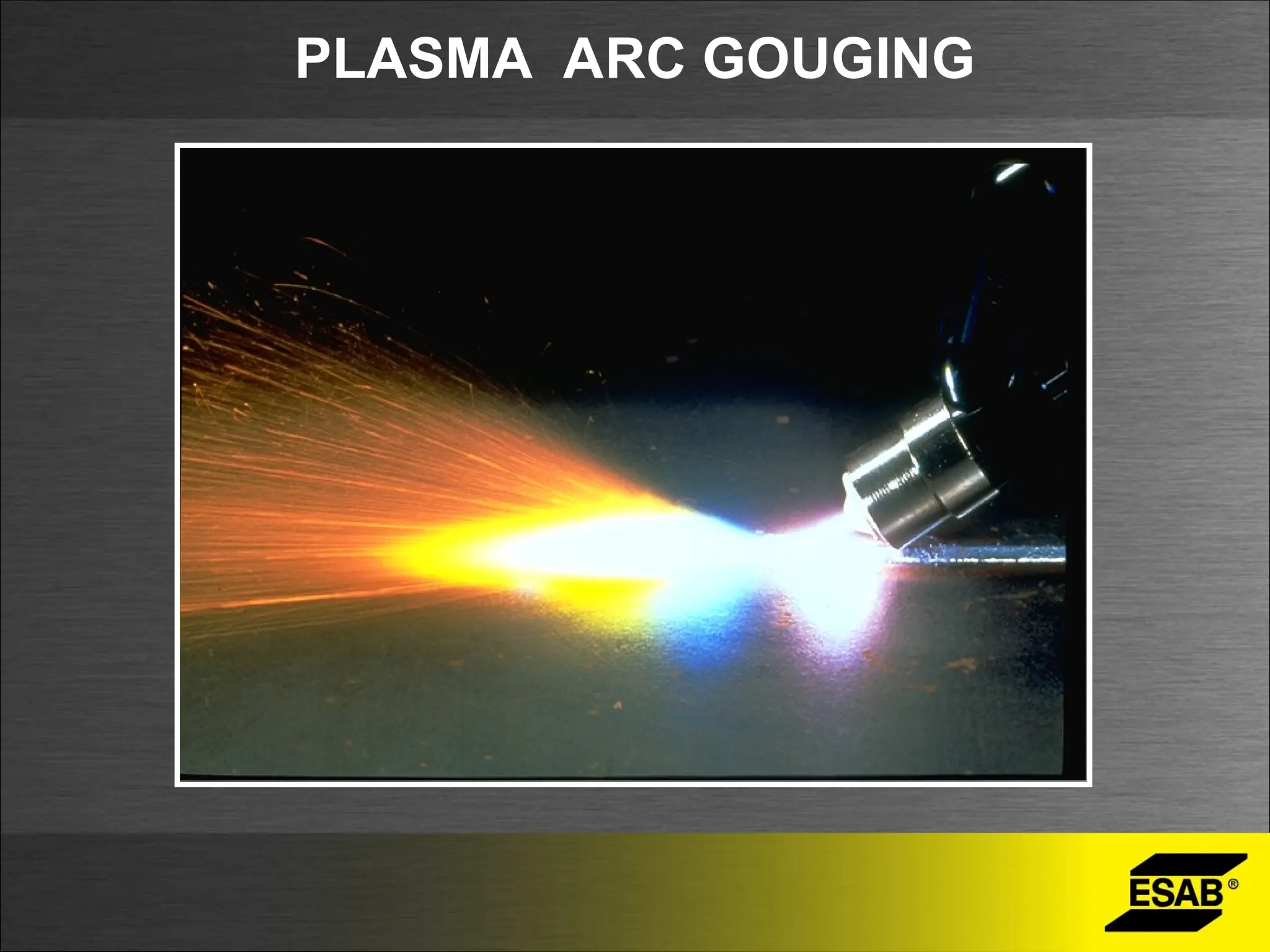

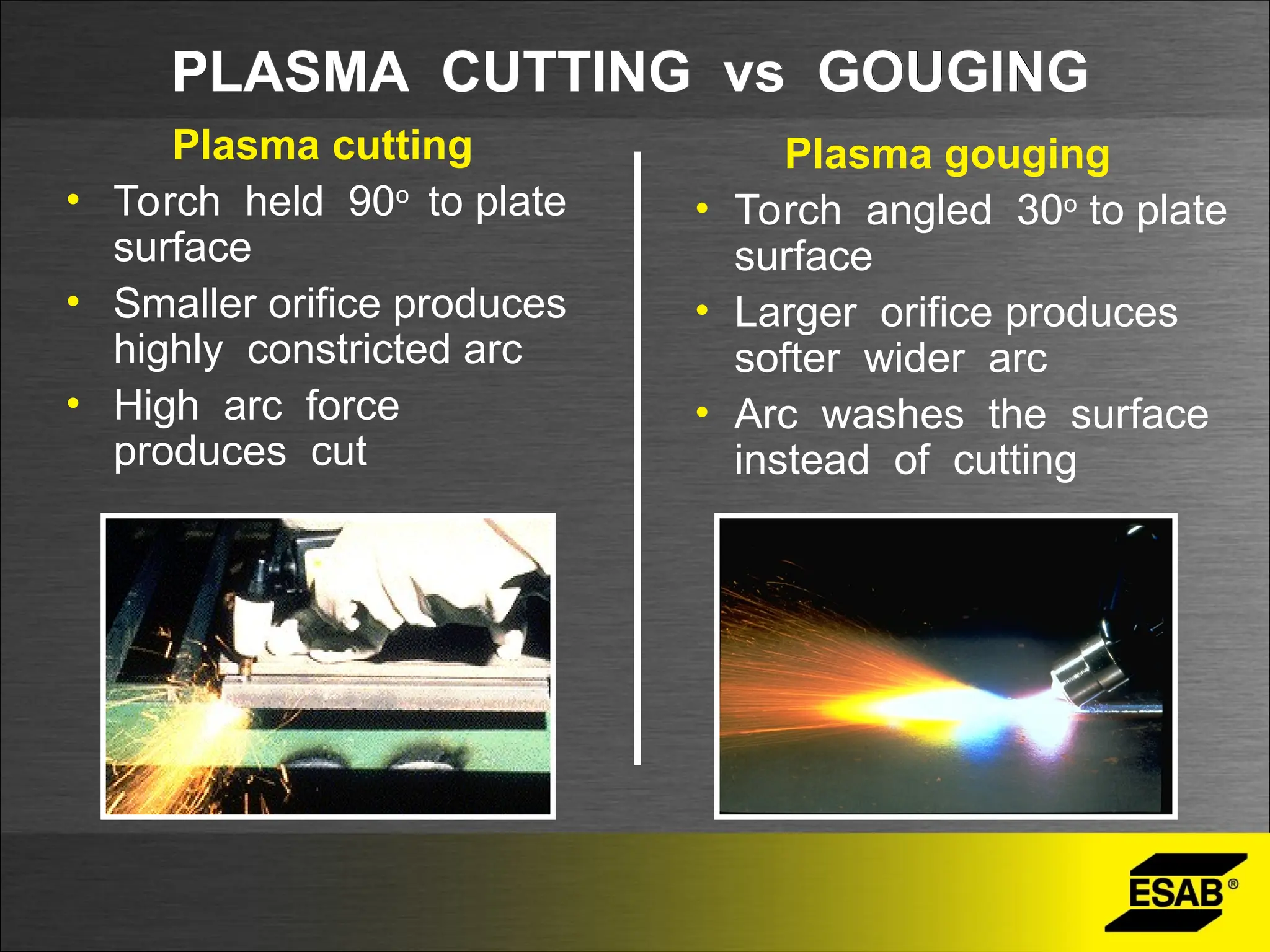

The document provides an overview of plasma cutting and gouging technologies, detailing methods such as mechanical cutting and plasma processes. It explains the characteristics of plasma arcs, including their temperature and velocity, and offers operational tips for using various plasma torches effectively. Additionally, it compares plasma cutting and gouging techniques, highlighting their differences and advantages over traditional methods.