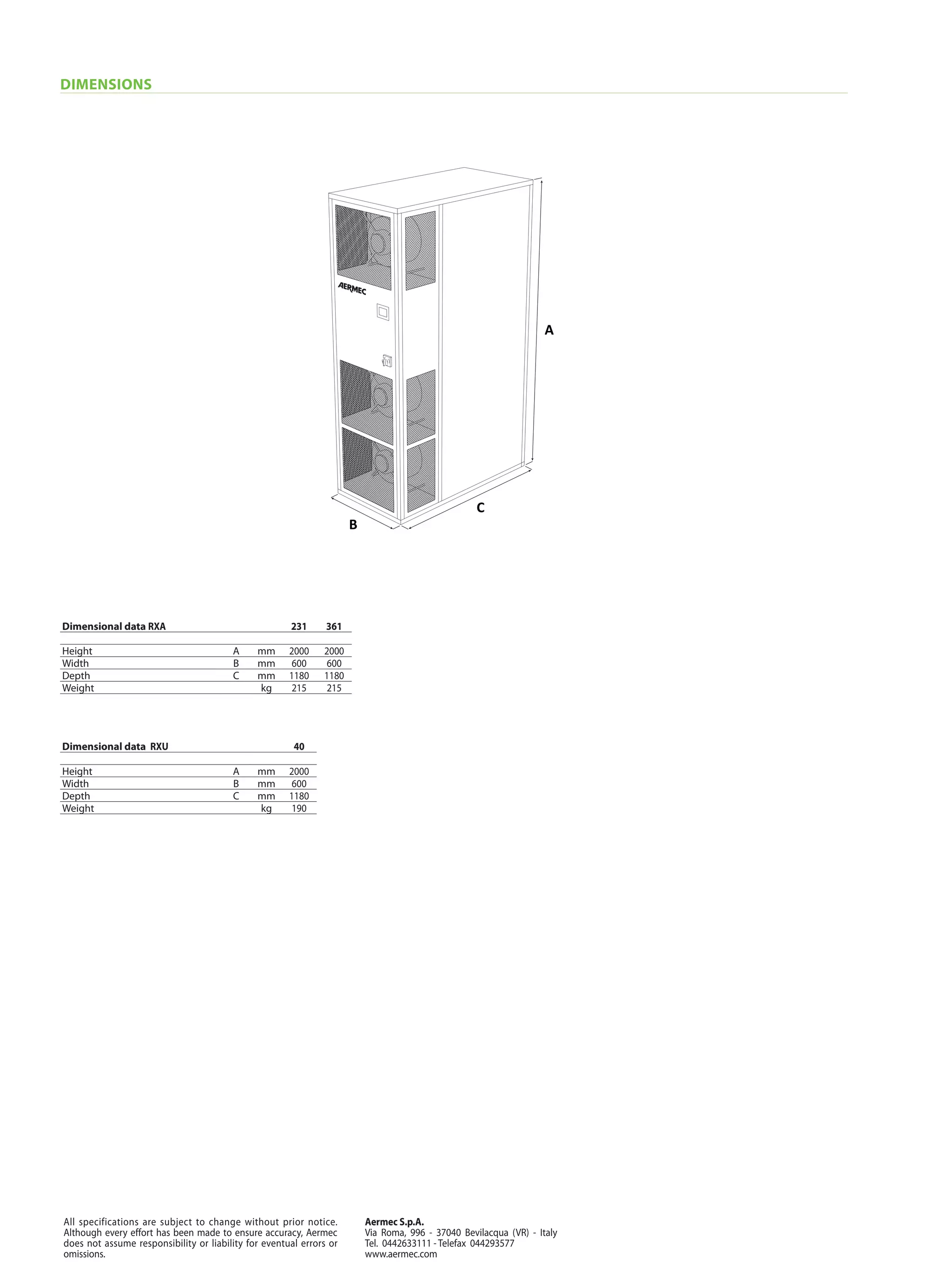

The document provides specifications and features for the R Series precision air conditioners, designed for data centers with optimal cooling configurations. It highlights components such as compressors, fans, and filters, emphasizing energy efficiency, modularity, and control systems for real-time monitoring. Additionally, it discusses the innovative SmartNet system for workload distribution among multiple units to ensure continuous operation and redundancy.