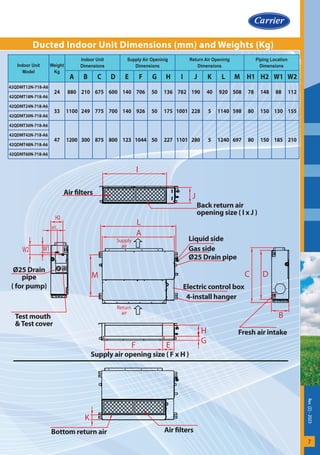

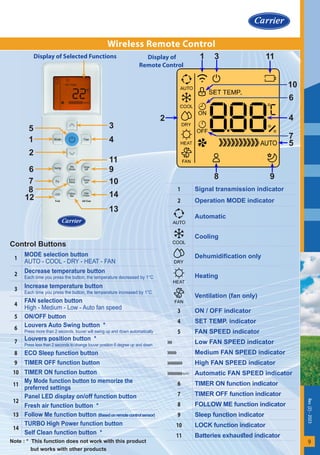

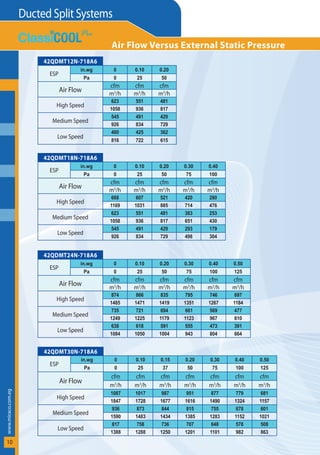

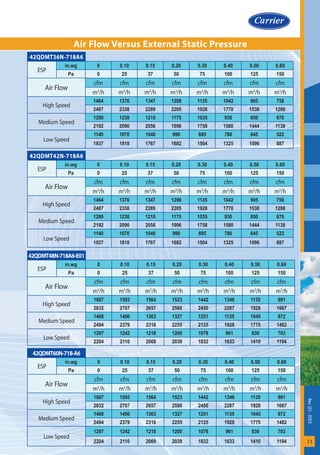

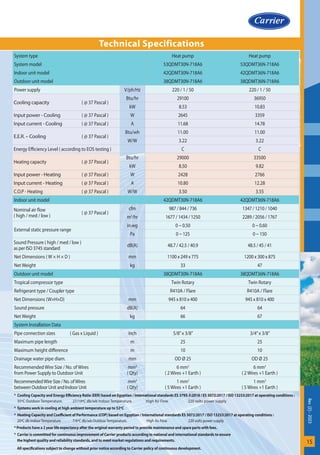

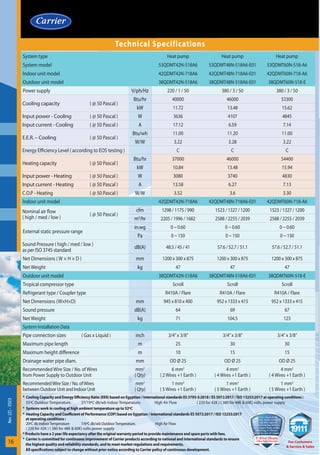

The document details specifications and features of a range of heat pump ducted split systems from Miraco, including various model capacities (12k to 60k) and their operating efficiencies. It highlights advanced technology such as high-temperature operation, energy-saving designs, and smart control options like wired and wireless remotes. The systems are suited for both residential and light commercial applications, emphasizing their compact design and easy installation.