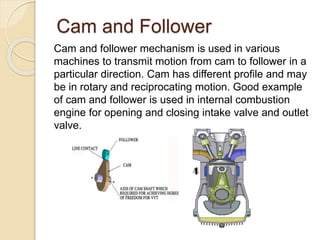

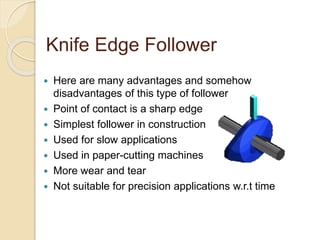

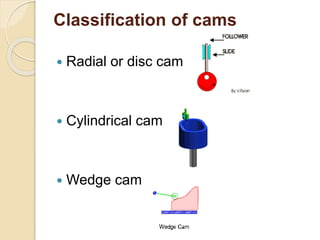

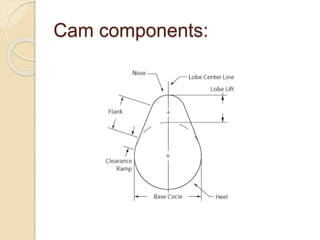

The document outlines a project focused on the motion analysis of a quick return mechanism using a cam-follower system, detailing the components such as cams, followers, bearings, and shafts. It describes various types of cams and followers, their classifications, and applications, particularly in shaping machines and internal combustion engines. Additionally, it discusses the design and manufacturing processes involved in creating the cam follower apparatus, including specifications and methods of production.