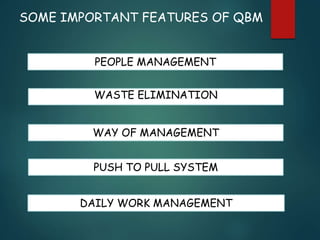

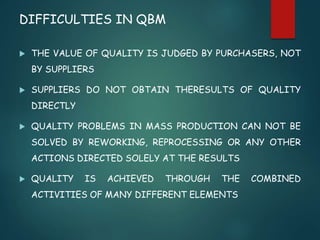

Quality Based Management (QBM) focuses on customer satisfaction by prioritizing the fulfillment of customer requirements over short-term cost objectives. It emphasizes continuous improvement and involvement of all organization members in enhancing processes to meet customer expectations. Key strategies include waste elimination, a pull system for production, and a commitment to producing quality products while reducing delivery timelines.