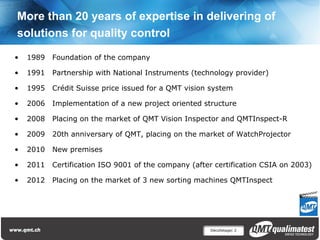

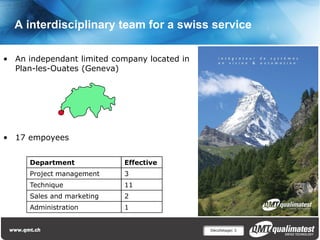

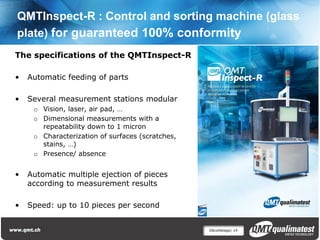

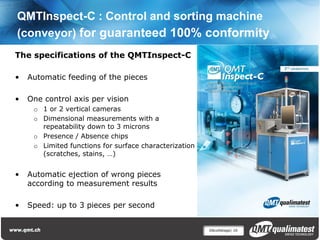

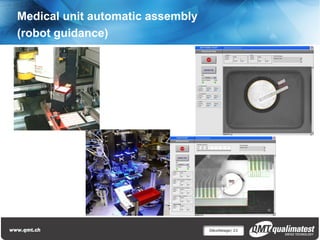

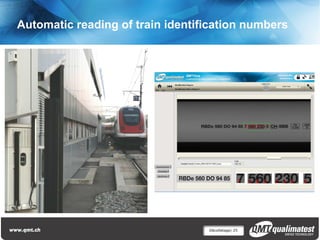

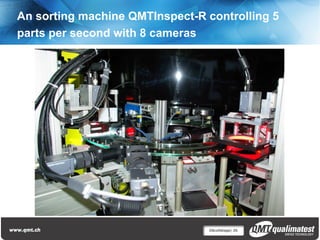

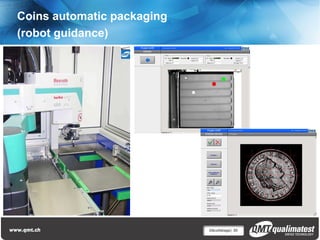

Qualimatest SA specializes in automatic quality control solutions, focusing on various industries including watchmaking, railway, automotive, and medical. With over 20 years of expertise, the company offers a range of products like vision systems and sorting machines, maintaining more than 300 systems globally. They emphasize the importance of reliability, effective project management, and high-level service, supported by ISO 9001 certification.