1. BIS XL 8 pages.pdf

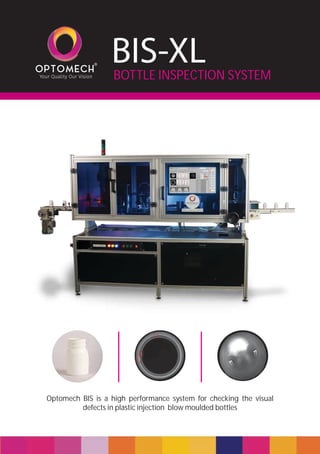

- 1. Optomech BIS is a high performance system for checking the visual defects in plastic injection blow moulded bottles BOTTLE INSPECTION SYSTEM BIS-XL

- 2. Salient features During the process of bottle manufacturing a number of defects are generated,due to unavoidable conditions such as temperature variations, raw material defects, contaminations etc. But customers today are becoming more and more demanding and have zero tolerance for defective products.It is essential for bottle manufacturing companies to inspect 100% of their product. It is not possible to do so anymore by the traditional methods of manual checking and sorting. The BIS-XL is a high performance system which does 100% inspection and sorting of bottles for all possible defects automatically and ensures peace of mind for manufacturers as well as their customers. • Easy to define tolerances allow the user to decide which bottles need to be accepted or rejected. • System changes over quickly to inspect new products.Changeover involves simply selecting the required product from the system library using the touch screen. • Large monitor displays the image of the bottles as they are passing through the system. • Periodic reports are generated as per user defined frequency eg.hourly, daily, weekly etc. • Each bottle is inspected for defects like spots, material inclusions, color smears, color shade variations, flashes, ovality, diameter variations, holes and transparency. • High speed, machine vision cameras, precision optics and customised lighting coupled with state of the art 21 CFR Part 11 compliant software provide security, accuracy and repeatability. • 3 Level access control for‘User’, ‘Supervisor’and ‘Administrator’ through separate passwords. • All the product data is stored in a database and can be retrieved at any time.

- 3. • Eight cameras capture images of the full 360° view of the surface including the thread area. • Two cameras inspect the bottles for defect in the top sealing surface and bottom area . • One camera inspects the bottle from inside. • Large monitor displays the images of the bottles as they are passing through the system. • Results of the last 100 bottles are displayed onscreen. • Vision system consists of eleven high speed machine vision cameras, high resolution optics and custom designed lighting. • Bottles are transported through the system with the help of two conveyors. • Ergonomically designed enclosure with alarm and door interlocks to prevent accidental opening during process. • Data processing unit with 21“ touch screen monitor. • Pneumatic ejection mechanism to eject the rejected bottles. Hardware • Bottles are picked-up from the blow molding machine’s conveyor by a clamp conveyor provided in the bottle inspection system. • From the clamp conveyor the bottles are transferred to the flat belt conveyor. • As the bottles pass through the system the high speed camera capture images of the bottles from all directions, the images are processed in realtime to detect the defective bottles. • Defective bottles are ejected from the system with the help of the pneumatic ejection mechanism. Inspection Process Multiple camera provide all round inspection Stand alone system integrates directly into the production process

- 4. TOP SEALING SURFACE • Thread Damage • Contamination • Black spots • Incomplete blowing NECK/THREAD AREA CONTAINER BASE • Pin Hole • Incomplete blowing • Black spots • Transparency • Flashes and extra material • Under/Short molding • Ovality • Diameter Variation OUTER SIDEWALL • Bottle shape variation • Incomplete blowing • Color Shade Variation • Black spots • Burn spots • Coving • Short molding • Extra material • Ovality • Holes • Thin wall INSIDE THE BOTTLE • Dark spots • Mateial Insert • Contamination Typical Defects

- 5. Set Up • Add/teach new products: Can be done easily by following a few simple steps in the software.The system can be set up for hundreds of different bottles. • Advanced learn capability: User can set the parameters which define the criteria for acceptance or rejection of the bottle,just by passing a few‘good’bottles,and a few ‘defective’bottles,the system will then automatically set the parameters. • Customization: User can choose the defects to be detected, define the tolerances for each defect and define the area to be inspected. • All the user settings are saved in a database. Results • The results of the last 100 bottles are displayed onscreen. • The photos of the defective bottles are stored, in the database, they can be recalled for review anytime in the future. • The inspection results are stored in the database product wise. Reporting • Reports can be exported to excel. • Reports can be exported over the network. • System can be configured to automatically generate an excel report at a predefined time, and send over the network. • The user can at any time select the product and a start and end date. The software will generate reports on the • Number of bottles inspected per shift • Number of defective bottles per shift classified as per the defect classes. Inspection results are stored in the data base product wise Detailed statistical reports can be generated and viewed in excel

- 6. Technical Specifications 11,000 bottles per hour maximum Speed Optomech bottle inspection system Model Bottle Size 200 mm maximum Height Bottle Size Bottle Size 110 mm maximum Width 95 mm maximum Depth/Diameter 25 mm Min gap between bottles 0.1 mm for bottle height of 50mm Accuracy Defects Detected Material inclusions,black spots,holes,thin wall Outer Sidewall Flashes,short molding,ovality,diameter variation Top Sealing Surface Thread damage,contamination,holes,black spot Neck/Thread Area Speed Contamination,thin wall,holes,incomplete blowing Container Base Dark spots,material insert,contamination Inside Machine Size 2750 mm,1000 mm,1800 mm Length,Width,Height 150 kg Weight Conveyor Utilities Service conditions 40% - 90% RH,non-condensing Humidity +10° C to +40° C Temperature 6-10 bar,oil free clean air,push in connection 6 mm Compressed Air AC 415 V,3 phase,5 A Electric Upto 30 m/min Belt speed From 930 mm to 1290 mm Conveyor Height (Adjustable) Belt width:60 mm Length:480 mm Clamp Conveyor Belt width:100 mm Length:4660 mm Main Conveyor 1900 m Maximum operating altitude

- 7. Machine Dimensions Motorised height adjustment to match the IBM machine conveyor Over all length - 2830 mm Over all width - 1000 mm Maximum height - 1790 mm Min. height of main conveyor - 930 mm OPTOMECH Optics for measurement POWER STOP SIDE MAIN START CONVEYOR CAMERA UNIT VISION SYSTEM CONVEYOR START START STOP MAIN SIDE POWER OPTOMECH Optics for measurement BOTTLE INSPECTION SYSTEM Over all length - 2830 mm OPTOMECH Optics for measurement POWER STOP SIDE MAIN START CONVEYOR CAMERA UNIT VISION SYSTEM CONVEYOR START START STOP MAIN SIDE POWER OPTOMECH Optics for measurement BOTTLE INSPECTION SYSTEM Over all width - 1050 mm Maximum height - 2150 mm Max. height of main conveyor - 1290 mm

- 8. Canister Inspection System Induction Seal Integrity Verification System Quick Measuring Machine Some of our esteemed customers: Some of the other optical metrology products manufactured by optomech are... Optomech Engineers Pvt. Ltd. was founded in Hyderabad, India in the year 1981. Optomech has over 37 years of experience of successful development, manufacturing, servicing and marketing of products involving vision technology for quality inspection. We are closely orientated towards the needs of the market. We are one of the leading providers of vision technologies for quality inspection. Renowned companies place their trust in the solutions and services provided by Optomech. For us at Optomech, ‘Professional After-Sales Service’ is not just a simple catch phrase; instead, it is our company philosophy. We accompany you all the way from the initial consultation up to final installation and training – and beyond. You will benefit from our many years of experience and will be able to deal with the challenges encountered when implementing the new technology. Optomech has a well equipped optical and mechanical design and fabrication facility at its works at Hyderabad which is ably supported by a team of motivated and trained engineers for installation, commissioning, training and after sales services of its equipments. Optomech specializes in the development and manufacturing of quality control equipments based on optical and video imaging technologies. Optomech Engineers Pvt Ltd 3A Type II, I.E.,Kukatpally,Hyderabad 500 072,Telengana India Ph: +91 40 23078371 sales@optomech.in www.optomech.in We reserve the right to modify the product specifications, in the interest of product development ®