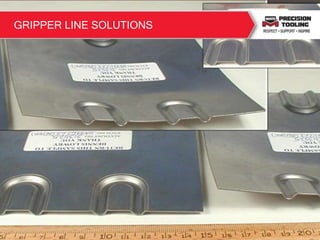

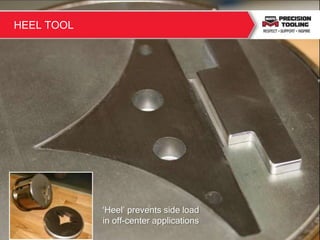

This document discusses various techniques for punching and forming sheet metal while avoiding curling. It presents solutions such as using a gripper line around the embossing to isolate the forming area, a relieved stripper and die, and ensuring the sheet border and areas near holes remain unaffected. Various techniques are shown that can pierce, emboss, and extrude the sheet metal in a single hit or through progressive multiple hits.