PSI-130-30-0002-RC-R1_Agitators.pdf

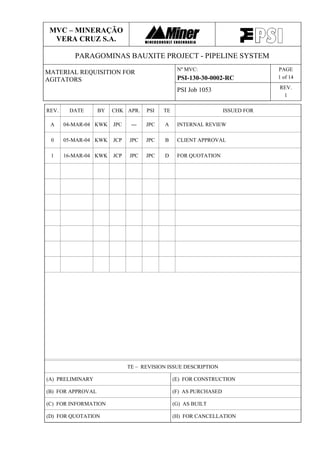

- 1. MVC – MINERAÇÃO VERA CRUZ S.A. PARAGOMINAS BAUXITE PROJECT - PIPELINE SYSTEM Nº MVC: PSI-130-30-0002-RC PAGE 1 of 14 MATERIAL REQUISITION FOR AGITATORS PSI Job 1053 REV. 1 REV. DATE BY CHK APR. PSI TE ISSUED FOR A 04-MAR-04 KWK JPC --- JPC A INTERNAL REVIEW 0 05-MAR-04 KWK JCP JPC JPC B CLIENT APPROVAL 1 16-MAR-04 KWK JCP JPC JPC D FOR QUOTATION TE – REVISION ISSUE DESCRIPTION (A) PRELIMINARY (E) FOR CONSTRUCTION (B) FOR APPROVAL (F) AS PURCHASED (C) FOR INFORMATION (G) AS BUILT (D) FOR QUOTATION (H) FOR CANCELLATION

- 2. MATERIAL REQUISITION FOR AGITATORS PSI-130-30-0002-RC-R1 Page 2 of 14 PSI Job 1053 TABLE OF CONTENTS 1.0 GENERAL ............................................................................................................................3 1.1 Definitions and Project Specifics ...............................................................................3 2.0 SCOPE OF WORK AND PRICING..................................................................................4 2.1 Work Included............................................................................................................4 2.2 Work Not Included.....................................................................................................5 3.0 DRAWING AND DATA REQUIREMENTS....................................................................6 3.1 Mailing Instructions ...................................................................................................6 3.2 Time Limits................................................................................................................6 3.3 Drawings and Documents ..........................................................................................6 3.4 Bill of Material...........................................................................................................7 3.5 Drawings and Documents to be Submitted................................................................7 3.6 Installation, Operation & Maintenance Manuals .......................................................7 4.0 TECHNICAL SPECIFICATIONS AND ATTACHMENTS...........................................9 4.1 Technical Notes..........................................................................................................9 5.0 QUALITY SURVEILLANCE ..........................................................................................10 5.1 Initial Visit and Notification ....................................................................................10 5.2 Definitions................................................................................................................11 5.3 Levels of Quality Surveillance.................................................................................11 5.3.1 Level 1 - Final Quality Surveillance Prior to Shipment............................11 5.3.2 Level 2 - Limited Scope Quality Surveillance..........................................11 5.3.3 Level 3 - Full Scope Quality Surveillance ................................................11 5.3.4 Level 4 - Resident Quality Surveillance ...................................................12 5.4 Quality Surveillance Plan.........................................................................................12 6.0 ACCEPTANCE MEASUREMENT CRITERIA ............................................................14

- 3. MATERIAL REQUISITION FOR AGITATORS PSI-130-30-0002-RC-R1 Page 3 of 14 PSI Job 1053 1.0 GENERAL This material requisition is for SLURRY STORAGE TANK AGITATORS. 1.1 Definitions and Project Specifics Owner Companhia Vale do Rio Doce S.A. (CVRD) Buyer CVRD Vendor Engineer Pipeline Systems Incorporated (PSI) Equipment Slurry storage tank agitators Working Languages English and Portuguese Units SI 1.2 Buyer would like to have the option of purchasing the following components from Brazilian Manufacturers: • Gear Reducers ( Falk / PTI or Flender ) • Motors ( Gevisa or WEG )

- 4. MATERIAL REQUISITION FOR AGITATORS PSI-130-30-0002-RC-R1 Page 4 of 14 PSI Job 1053 2.0 SCOPE OF WORK AND PRICING 2.1 Work Included The work includes furnishing all labor, materials, and equipment and the performance of all operations and incidentals necessary for designing, detailing, furnishing, fabrication, testing, and delivery of SLURRY STORAGE TANK AGITATORS suitable for the intended service. The work shall include, but not necessarily be limited to, the following items: Item No. Qty Description Unit Price (US$) Extension (US$) A LOT Drawings and data shall be in accordance with the attached Drawing and Data Requirements (Section 3). B LOT Buyer quality surveillance in accordance with the attached Supplier Quality Surveillance Requirements (Section 5). C LOT Expediting and scheduling in accordance with the Owner’s Expediting Requirements. D LOT Tagging with stainless steel tags (foil strip is not acceptable) firmly attached by wire or screws to each item which is shipped separately. Each tag shall be stamped with: Purchase order no. Purchase order item no. Equipment/Instrument tag no. E LOT Export preparation and inland freight FOB port of exit. F 6 units Freight CIP port of Abaetetuba, near the city of Belem in the state of Pará in Brazil. G LOT Recommended spare parts for two (2) years operation (including listing). H LOT Recommended spare parts for start up and commissioning (including listing). I LOT Special tools. J ____ days Assistance for field assembly, erection, and installation (optional if requested). K ____ days Technician and helper for start up and commissioning assistance and supervision (optional if requested). L ____ days Technical support after commissioning to include a technician and helper (optional if requested).

- 5. MATERIAL REQUISITION FOR AGITATORS PSI-130-30-0002-RC-R1 Page 5 of 14 PSI Job 1053 Item No. Qty Description Unit Price (US$) Extension (US$) M ____ days Services of qualified representatives to train Buyer’s personnel in the use, care, and maintenance of those goods identified in this requisition (optional if requested). 1-A 4 Mine site bauxite concentrate storage tank agitator. Equipment Tag Nos.: AG-131-01, - 02, -03 and -04 1-B 2 Terminal site bauxite concentrate storage tank agitator. Equipment Tag Nos.: AG-134-01 and -02 1-C LOT It is intended that the Vendor shall furnish complete operating units (Referring to items 1-A and 1-B) that require minimal field assembly. Each agitator shall include, but is not necessarily limited to, the following: a) Impeller with removable/adjustable blades b) Shafts, bearings, and seals c) Electric motor, coupling, drives, OSHA guards, and steel baseplate d) Corrosion and abrasion protective coating e) Painting per Technical Specification MEL-000-30-0001-ET f) Load information for support bridge design by Others g) Design of tank baffles, fillet, wear plate, or other design recommendation for structures to be provided by Others h) Shop assembly and run testing 2.2 Work Not Included A) Foundation and foundation bolts. B) Labor, equipment, and ordinary tools for unloading, erection, installation, and field testing. C) Conduit, wire, and cable external to the agitator. D) Power supply external to the machines. E) Agitator support bridge, access ladders, and platforms. F) Motor starters and controls G) Lubricants other than what is needed for shop testing and assembly, initial running and normal operation for three months.

- 6. MATERIAL REQUISITION FOR AGITATORS PSI-130-30-0002-RC-R1 Page 6 of 14 PSI Job 1053 3.0 DRAWING AND DATA REQUIREMENTS 3.1 Mailing Instructions Drawings and documents are to be forwarded to: Companhia Vale do Rio Doce (CVRD) Rua Paraiba, 1122 – 12° andar – Funcionários CEP: 30.130-141 – Belo Horizonte – MG – Brasil Telephone: (031) 3228-4600 Telefax: To Be Provided Attention: CVRD – Mineração Bauxita Paragominas Pipeline Purchasing 3.2 Time Limits “Time,” as stated in the table below, is the number of weeks after purchase award to receipt by Pipeline Systems of INITIAL drawings and the number of weeks after return of reviewed Initial drawings to receipt by Pipeline Systems of FINAL drawings. 3.3 Drawings and Documents Vendor’s drawings and documents will be reviewed only as to overall compatibility and conformance with interface requirements and related drawings, and such review shall not be construed to relieve or mitigate the Vendor’s responsibility for accuracy or adequacy and suitability of materials and/or equipment represented thereon. Both initial and final drawings shall have dimensions in the SI metric system. Other units may be shown in parentheses. Instruction manuals shall be in both the English and Portuguese languages. A) PROPOSAL DRAWINGS AND DOCUMENTS shall be the Manufacturer’s standard drawings in sufficient detail to lay out the equipment, drives, and access for maintenance and operations and for the design of foundations and supports. B) INITIAL DRAWINGS AND DOCUMENTS shall be prints complete with equipment number(s) and purchase order number. Initial drawings must show all information necessary for Buyer’s design of the foundations and any connections to other equipment. C) FINAL DRAWINGS AND DOCUMENTS preferably shall be in electronic format as follows: 1) Drawing files preferably shall be in AutoCAD or Microstation formats. Alternatively, if AutoCAD or Microstation formats are not available, the drawing files shall be in DXF format. An Adobe Acrobat pdf version shall additionally be provided for each document. 2) Document files shall be in Microsoft Excel or Microsoft Word formats. An Adobe Acrobat pdf version shall also be provided for each document.

- 7. MATERIAL REQUISITION FOR AGITATORS PSI-130-30-0002-RC-R1 Page 7 of 14 PSI Job 1053 Electronic files shall be submitted on compact disc (CD). Alternatively, submittal of electronic files via the Internet or some other means can be arranged upon request. Specific versions of all software used shall be agreed upon prior to submittal of any electronic files. For final drawings and documents, a signed “Letter of Transmittal” must accompany the electronic file indicating that the drawing is “CERTIFIED.” Alternatively, final drawings and documents may be furnished as legible mylars complete with equipment number(s), and purchase order number, stamped CERTIFIED and signed by a person authorized to bind the partnership or corporation. Final documents which are full size “A” or “B” may be furnished as high quality hard copies in lieu of mylars. 3.4 Bill of Material A bill of material is required for each order prior to shipment to identify separate parts, subassemblies, or materials required for assembly by the field forces. 3.5 Drawings and Documents to be Submitted The following drawings and documents shall be submitted in the form designated: P = PRINT E = ELECTRONIC (COMPACT DISC) 3.6 Installation, Operation & Maintenance Manuals Final submittal of the I,O & M Manuals shall be both in English and Portuguese. Sub- supplier information may be in English only provided that Portuguese is not routinely available.

- 8. MATERIAL REQUISITION FOR AGITATORS PSI-130-30-0002-RC-R1 Page 8 of 14 PSI Job 1053 NUMBER, TIME, AND FORM REQUIRED I T E M DESCRIPTION REVIEW REQUIRED BEFORE FAB (YES/NO) PROPOSAL DRAWINGS AND DATA INITIAL TIME FINAL TIME 1 Descriptive literature (catalog information). 4P+1E 2 Index of all documentation to be submitted. 4P+1E 2P+1E 2 10P+1E 3 Schedule (dates) of all documentation to be submitted. 4P+1E 2P+1E 2 4 Fabrication schedule (dates). 4P+1E 2P+1E 2 5 Inspection and shipping schedule (dates). 4P+1E 2P+1E 2 6 Description of QA program per technical specification. 4P+1E 2P+1E 4 7 Manufacturing specifications per technical specification. 4P+1E 2P+1E 4 8 Delivery documentation per technical specification. 4P+1E 2P+1E 4 9 Dimensioned Outline Drawing. 4P+1E 2P+2CD 4 10P+1E+1CD (1) 10 Complete Parts List including Vendor’s and Original Manufacturer’s part numbers. 2P+1E 4 10P (2) 11 Structural support requirements (forces, moment, & deflection criteria). Y 4P+1E 2P+2CD 6 10P+1E+ 1CD (1) 12 Completed specification data sheets. Y 4P+1E 2P+1E 6 10P+1E (1) 13 Bearing life rating table. Y 4P+1E 2P+1E 6 14 Electrical Schematic and Wiring Diagrams. Y 4P+1E 2P+1E 6 10P+1E (1) 15 Assembly and Erection Drawings. Y 2P+1E 8 10P+1E (1) 16 Installation and Operation Manuals for Vendor’s and Original Manufacturer’s equipment. N 2P+1E 24 10P+1E (1) 17 Shipping weight. N 10P+1E (1) 18 Test Results, Certificates and Charts per Technical Specification. N 2P 24 10P+1E 19 Rubber lining and covering repair procedure Y 4P+1E 2P+1E 4 Notes: 1. Final and approved documents to be supplied with O&M Manuals prior to shipment. 2. Each copy shall be bound with each copy of the instruction manual. Final submittal of manuals shall be submitted on compact disc (CD).

- 9. MATERIAL REQUISITION FOR AGITATORS PSI-130-30-0002-RC-R1 Page 9 of 14 PSI Job 1053 4.0 TECHNICAL SPECIFICATIONS AND ATTACHMENTS The following documents cover the technical requirements for AGITATORS. Document No. Title MEL-000-30-0001-ET Technical Specification for Painting PSI-130-30-0001-ET Technical Specification for Mainline Pump Speed Reduction Gear PSI-130-30-0006-ET Technical Specification for Slurry Storage Tank Agitators PSI-130-51-0002-ET Technical Specification for Instruments, Controls, and Electrical Equipment Furnished with Mechanical Equipment 4.1 Technical Notes A) All manuals and instructions shall be in English and Portuguese, except for those submitted with the proposal, which shall be in English. B) All dimensions on drawings shall be in SI units (except for those submitted with proposal), which may be manufacturing standard. C) Vendor to identify shipping weights and volumes for all components, broken out by place of manufacture. D) All equipment supplied shall be designed to operate 24 hours per day, 365 days per year, as well as start up and operate at the ambient conditions specified. E) For project standardization purposes the Buyer may, but is not required to, select and assign a specific motor supplier for the project. F) Impeller shall be statically balanced. G) Exposed moving components shall be provided with OSHA1 and MSHA2 approved guards. Guards shall be designed for easy removal of components for maintenance purposes. H) Each agitator unit shall be shop tested in accordance with Vendor’s standard procedures. Vendor shall submit shop standard testing procedures with his proposal. 1 Occupational Safety and Health Administration 2 Mining Safety and Health Administration

- 10. MATERIAL REQUISITION FOR AGITATORS PSI-130-30-0002-RC-R1 Page 10 of 14 PSI Job 1053 5.0 QUALITY SURVEILLANCE The following quality surveillance clauses are an integral part of this material requisition. Buyer’s inspections shall not relieve the Vendor from any obligation to comply with the requirements of this material requisition. A) All materials and equipment listed in the purchase order and related parts are subject to quality surveillance by the Buyer’s representative/agent at the point of manufacture. B) Pre-inspection meetings may be initiated by the Buyer or Vendor when either party believes that such meetings are required in order to resolve questions involving compliance with the requirements of the purchase order including attached specifications. C) The Buyer’s supplier quality representative is required to reject any material that is not of acceptable quality or workmanship, or fails to comply with the specifications or other requirements of the purchase order. D) Vendor shall ensure that the required number of copies of material data, code forms, charts and other required information is provided to the Buyer’s supplier quality representative prior to final inspection. The Buyer’s supplier quality representative will not release the equipment or material until this data has been reviewed and is determined to be acceptable. Missing, incomplete, or incorrect documentation shall be treated as a nonconformance, and shall provide cause for denying the Vendor permission to release the material or equipment for shipment. E) In order to facilitate Buyer’s supplier quality activities, the Vendor shall allow the Buyer’s supplier quality representative free access to the Vendor’s manufacturing facilities at all times during manufacturing, and shall arrange similar access at the Vendor’s sub-supplier facilities. F) Vendor shall provide the Buyer’s supplier quality representative, without additional cost, all necessary facilities to be satisfied that the equipment is being satisfactorily fabricated and tested in accordance with the requirements of the purchase order including the attached specifications. Vendor shall incorporate these quality surveillance clauses in all suborders issued to sub-suppliers for any equipment or material required to be in compliance with this material requisition. 5.1 Initial Visit and Notification Prior to the start of manufacturing, the Buyer’s assigned supplier quality representative will conduct an initial visit meeting with the Vendor’s management to review the quality requirements of the purchase order including the attached specifications.

- 11. MATERIAL REQUISITION FOR AGITATORS PSI-130-30-0002-RC-R1 Page 11 of 14 PSI Job 1053 During manufacturing, the Vendor shall provide the Buyer’s supplier quality representative with at least five (5) working days notice to allow surveillance of designated “witness” or “hold” points. This notification can be direct from the Vendor or coordinated through the Buyer’s issuing office as mutually agreed between the Buyer and Vendor. 5.2 Definitions Quality Surveillance Quality surveillance is defined as the selected review, observation and evaluation of processes, procurement, manufacturing operations, quality control systems and programs to determine Vendor compliance with contractual quality requirements. Witness Points Witness points are defined as critical steps in manufacturing and testing, whereby the Vendor shall advise the Buyer’s supplier quality representative five (5) working days in advance of the operation so that it may be witnessed by the Buyer’s supplier quality representative. The Vendor may proceed with work past the witness point only if the Buyer’s supplier quality representative cannot attend. In the event a witness point is deferred by the Buyer’s supplier quality department, the next same operation will be witnessed. Hold Points Hold points are defined as critical steps in manufacturing and testing, whereby the Vendor shall advise the Buyer’s supplier quality representative five (5) working days in advance of the operation so that it may be witnessed by the Buyer’s supplier quality representative. The Vendor shall not proceed with work past the hold point without witness by the Buyer’s supplier quality representative, except by prior written agreement from the Buyer’s supplier quality department. 5.3 Levels of Quality Surveillance 5.3.1 Level 1 - Final Quality Surveillance Prior to Shipment Buyer’s supplier quality representative will witness specific activities and verify certain characteristics only prior to shipment. 5.3.2 Level 2 - Limited Scope Quality Surveillance Buyer’s supplier quality representative will perform predetermined surveillance of specific “witness” and “hold” points in accordance with the quality surveillance plan, and will witness specific activities and verify certain characteristics prior to shipment. 5.3.3 Level 3 - Full Scope Quality Surveillance In addition to the visits to perform surveillance of “witness” and “hold” points in accordance with the quality surveillance plan, the Buyer’s supplier quality

- 12. MATERIAL REQUISITION FOR AGITATORS PSI-130-30-0002-RC-R1 Page 12 of 14 PSI Job 1053 representative will visit the manufacturing facility on a regular basis to monitor the work in progress. The frequency of these visits will be determined by the activity of the purchase order and the quality history of the Vendor. 5.3.4 Level 4 - Resident Quality Surveillance Buyer’s supplier quality representative will be a resident in the manufacturing facility, and will continuously monitor the work in progress as well as perform surveillance of “witness” and “hold” points in accordance with the quality surveillance plan. 5.4 Quality Surveillance Plan The quality surveillance requirements of the purchase order are listed below. The Buyer’s supplier quality representative shall be afforded free access to all areas of the plant while any work or test is in progress on any major unit covered by this order, including work performed by sub-tier suppliers. The Vendor shall provide the Buyer’s supplier quality representative, without additional cost, all necessary reasonable facilities to be satisfied that the equipment is being fabricated and tested satisfactorily. LEVEL OF SURVEILLANCE 1 I INITIAL VISIT Review the technical and quality requirements of the purchase order, material requisition, specification and data sheets. II IN-PROCESS QUALITY SURVEILLANCE Not applicable. III WITNESS POINT Standard mechanical running test. IV HOLD POINTS Final inspection and release for shipment. V FINAL INSPECTION AND RELEASE FOR SHIPMENT AS FOLLOWS: Construction and Dimensions Check outline dimensions to reviewed drawings, tolerances, welds, materials of construction, cleanliness, and workmanship. Inspect Agitators and QA documentation at the Vendor’s factory prior to shipment. Confirm match marking for field assembled pieces. The Vendor will give the engineer five (5) days notice before each shipment.

- 13. MATERIAL REQUISITION FOR AGITATORS PSI-130-30-0002-RC-R1 Page 13 of 14 PSI Job 1053 Marking, Tagging and Traceability Verify marking and tagging for compliance with the technical specification and P.O. requirements. Packaging Verify packaging in accordance with the technical specification, including cleaning, painting, and preparation for shipment, closure of openings, protection of flange facings and machined surfaces, rust protection, proper dunnage, and tie-downs. Documentation Review all QA documentation required per the technical specification. Confirm completeness of Section 3, Drawing and Data Requirements. Check for accuracy and legibility. Vendor shall not ship any goods on this order until final inspection has been completed satisfactorily and a release for shipment is received from the Buyer’s supplier quality representative or shipment is authorized in writing by the Buyer. ORIGINATOR PROCUREMENT

- 14. MATERIAL REQUISITION FOR AGITATORS PSI-130-30-0002-RC-R1 Page 14 of 14 PSI Job 1053 6.0 ACCEPTANCE MEASUREMENT CRITERIA The criteria for accepting supplier payment requests for items on the item list above, and the percent payment allowed, shall be as follows: Documentation - Acceptance by Owner as approved: 100% Agitator Units: Invoiced by unit package price times the percentage as follows: Order Placed: 20% of total Factory Acceptance - Completed agitator and drive unit: 70% of total Installation Accepted: 10% of total Spare Parts: Upon shipment Service Items: Monthly upon completion Owner’s representative shall determine final percentages should disputes arise on document, materials or service items.