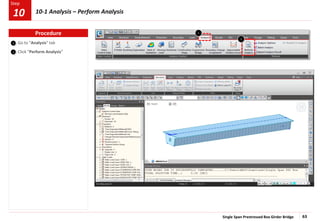

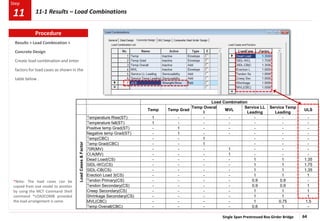

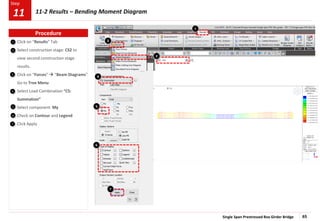

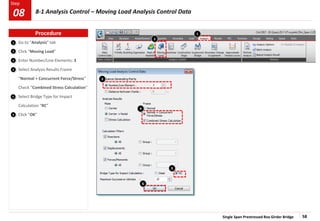

This document is a tutorial for creating a single-span prestressed post-tensioned box girder bridge using MIDAS Civil software. It covers various stages, including material and section definitions, geometric modeling, analysis control, and interpreting results, all based on the guidelines set by IRC codes. The tutorial includes step-by-step instructions for modeling, loading, analyzing, and designing the bridge components.

![Single Span Prestressed Box Girder Bridge 4

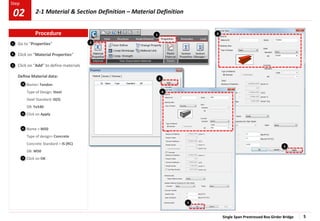

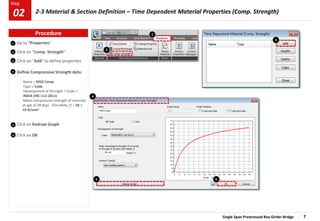

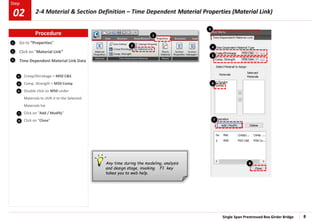

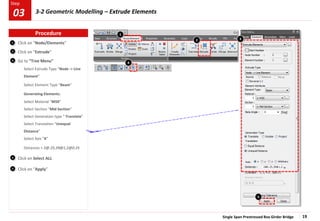

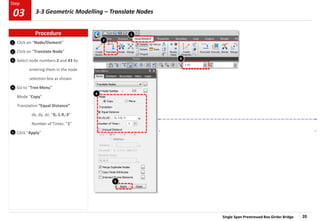

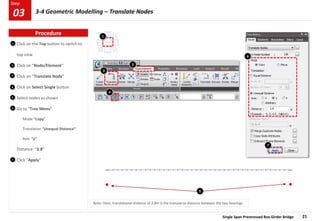

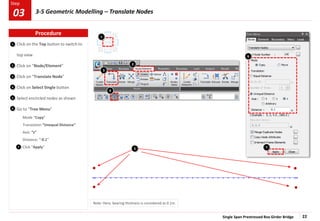

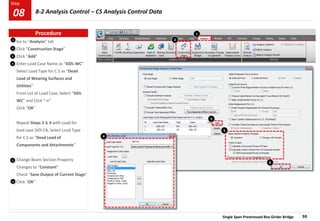

Step

Step

Invoke midas Civil

Open New File

Select the Unit System [ kN, m]

Save as ‘Single Span PSC Box Girder’

1

2

3

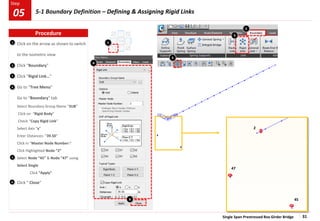

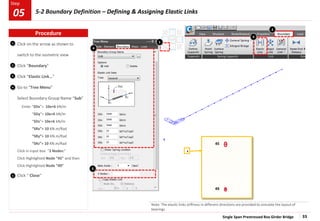

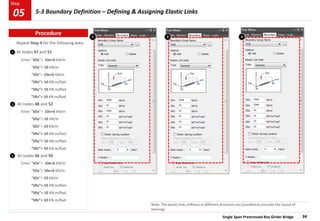

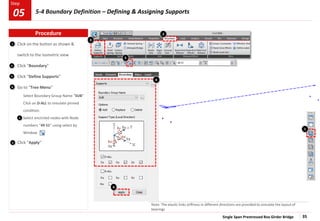

Procedure

.

3

2

1 Initial Setting

01

1](https://image.slidesharecdn.com/3pscboxbridgesinglespan-241018000504-50a634e5/85/PSC-Box-Bridge-Single-Span-for-structural-engineers-4-320.jpg)

![Single Span Prestressed Box Girder Bridge 6

Step

Step

1

2

3

4

5

Change unit system [ N, mm ]

Go to “Properties”

(Creep/Shrinkage)”

Click on “Add” to define properties

Define Creep / Shrinkage data:

Name > M50 C&S

Code > INDIA (IRC:112-2011)

Compressive strength of concrete at

the age of 28 days > 50 N/mm2

Relative Humidity of ambient

environment (40–99) > 70

Notational size of member > 1000mm

Age of concrete at the beginning of

shrinkage > 3 days

Click on Show Result to see the graph

Click on OK to add the C&S property.

7

6

2

3

4

6 7

Note: To get the creep & shrinkage strains, the value of relative humidity is to be considered as 70%, Notational size of member, h as

1000mm and Age of concrete at the beginning of shrinkage as 3 days. Later, the h value would be automatically updated for

composite sections

1

5

Procedure

02 2-2 Material & Section Definition – Time Dependent Material Properties (Creep &Shrinkage)](https://image.slidesharecdn.com/3pscboxbridgesinglespan-241018000504-50a634e5/85/PSC-Box-Bridge-Single-Span-for-structural-engineers-6-320.jpg)

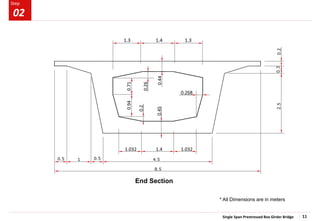

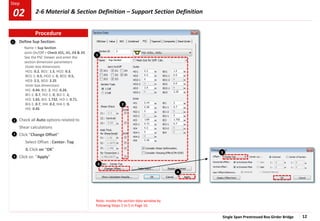

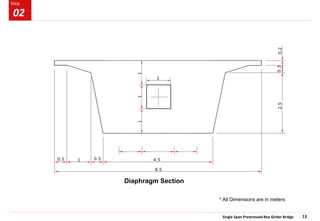

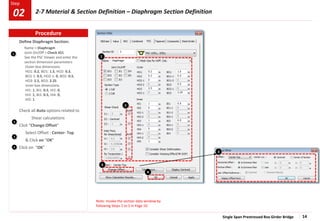

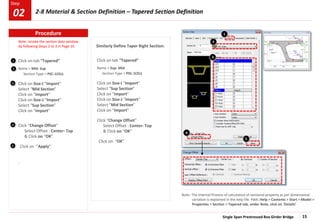

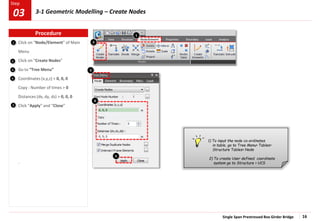

![Single Span Prestressed Box Girder Bridge 10

Step

Step

1

2

4

5

Change unit system [ KN, m ]

Go to “Properties” > Section

Properties”

Click on “Add..”

Click on tab “PSC”

Select: ‘PSC-1Cell, 2Cell’ type

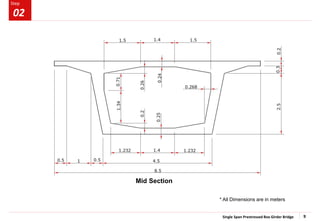

Define Mid Section:

Name > Mid Section

Joint On/Off > Check JO1, JI1, JI3, JI5

See the PSC Viewer and enter the

section dimension parameters

Outer box dimensions

HO1: 0.2, BO1: 1.5, HO2: 0.3,

BO1-1: 0.5, HO2-1: 0, BO2: 0.5,

HO3: 2.5, BO3: 2.25

Inner box dimensions

HI1: 0.24, BI1: 2.2, HI2: 0.26,

BI1-1: 0.7, HI2-1: 0, BI2-1: 2.2

HI3: 2.05, BI3: 1.932, HI3-1: 0.71,

BI3-1: 0.7, HI4: 0.2, HI4-1: 0,

HI5: 0.25

Check all Auto options related to

Shear calculations

Click “Change Offset”

Select Offset : Center- Top

& Click on “OK”

3

Note: The internal Process of section offset is explained in the help file .

Path: Help > Contents > Start > Model > Properties > Section, When Section

tab is opened under offset, click on ‘Details’

6

8

7

2

4

9

1

Click “Show Calculation Results”

Click on “Apply”

10

5

3

6

10

8

7

9

8

Procedure

02 2-5 Material & Section Definition – Mid Section Definition](https://image.slidesharecdn.com/3pscboxbridgesinglespan-241018000504-50a634e5/85/PSC-Box-Bridge-Single-Span-for-structural-engineers-10-320.jpg)

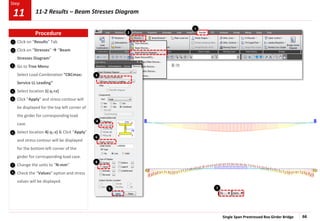

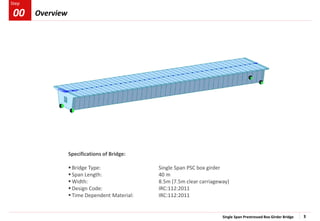

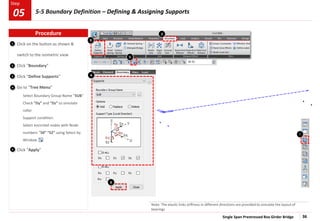

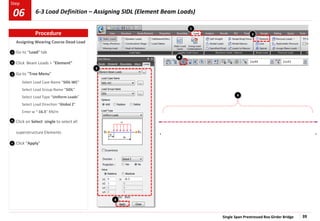

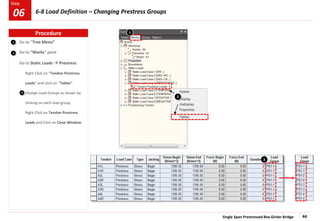

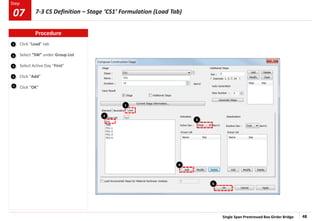

![Single Span Prestressed Box Girder Bridge 41

Step

Step

1

2

3

Change unit system [N,mm]

Go to “Load” of Main Menu

Click “Temp/Prestress”

Click “Tendon Property”

Click “Add”

Enter Tendon Name “Tendon”

Select Tendon Type “Internal(Post-

Tension”

Select Material “Tendon”

Click “…” in the dialog box for Total

Tendon Area

Select Strand Diameter

“15.2mm(0.6”)”

Enter Number of Strands “19”

Click “OK”

Enter Duct Diameter “110”mm

Select Relaxation Coefficient “India

(IRC:112-2011) – Low”

Enter Ultimate Strength “1860”

Enter Yield Strength “1581”

Enter Curvature Friction Factor

“0.17”

Enter Wobble Friction Factor as

“2e-6”/mm

Enter Anchorage Slip Begin : “6”

Enter Anchorage Slip End : “6”

Select Bond Type “Bonded”

Click “OK”

Click “Close”

4

2

3

1

4

5

7

7

5

6

6

Procedure

6-5 Load Definition – Defining Tendon Property

06](https://image.slidesharecdn.com/3pscboxbridgesinglespan-241018000504-50a634e5/85/PSC-Box-Bridge-Single-Span-for-structural-engineers-41-320.jpg)

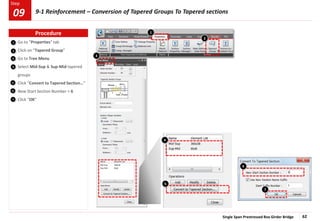

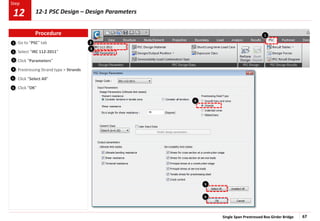

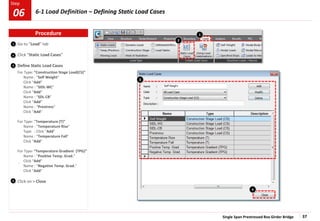

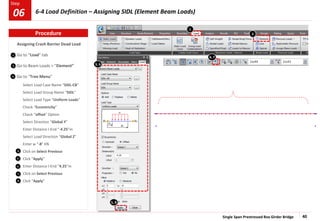

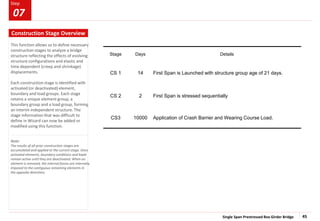

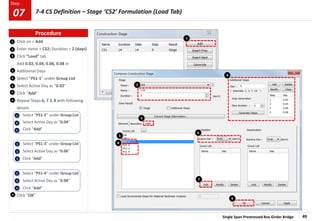

![Single Span Prestressed Box Girder Bridge 52

Step

Step

3

1

2

3

Go to “Load” tab

Click “Temp/Prestress”

Click “Beam Section Temp.”

Select all superstructure elements.

Go to “Tree menu”

Select Load Case name as “Positive

Temp. Grad.”

Section Type > PSC/Composite

Select “Element” option for Material

Keep Ref. as “Top”

B > “Section”

Enter H1 as 0 mm

Enter H2 as 150 mm

Enter T1 as 17.8 [C]

Enter T2 as 4 [C]

Click on Add

Change Parameters:

Enter H1 as 150 mm

Enter H2 as 400 mm

Enter T1 as 4 [C]

Enter T2 as 0 [C]

Click on Add

Change Parameters:

Enter H1 as 2850 mm

Enter H2 as 3000 mm

Enter T1 as 0 [C]

Enter T2 as 2.1 [C]

Click on Add

Click “Apply”

4

5

If temperature units are in degree Fahrenheit, one can change to degree Celsius from Tools Unit System

6

6

h1 = 0.15m

h2 = 0.25m

h3 = 0.15m

Positive Temperature

Differences

Reverse Temperature

Differences

h1

h2

h3

h1

h2

h3

h4

h1 = h4 = 0.25m

h2 = h3 = 0.25m

For the given depth of box girder

4

2 5

1

Procedure

6-10 Load Definition – Assigning Positive Temperature Differences (Beam Section Temperature)

06](https://image.slidesharecdn.com/3pscboxbridgesinglespan-241018000504-50a634e5/85/PSC-Box-Bridge-Single-Span-for-structural-engineers-52-320.jpg)

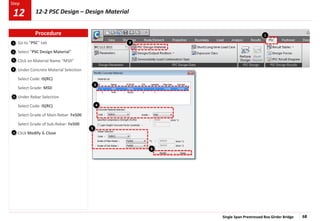

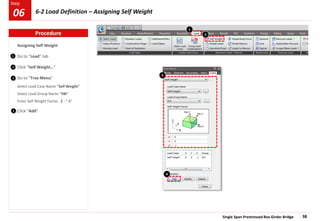

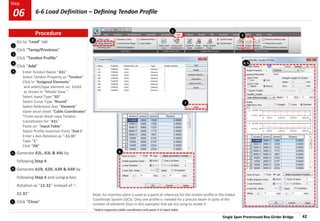

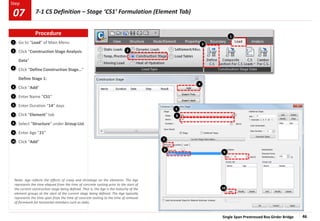

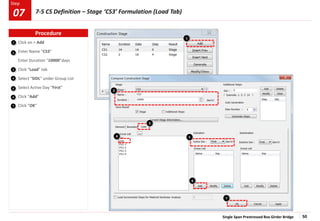

![Single Span Prestressed Box Girder Bridge 53

Step

Step

Change Parameters:

Enter H1 as 2750 mm

Enter H2 as 3000 mm

Enter T1 as -0.8 [C]

Enter T2 as -6.6 [C]

Click “Apply”

1

2

3

Go to “Load” tab

Click “Temp/Prestress”

Click “Beam Section Temp.”

Select all superstructure elements.

Go to “Tree menu”

Select Load Case name as “Negative

Temp. Grad.”

Section Type > PSC/Composite

Select “Element” option for Material

Keep Ref. as “Top”

B > “Section”

Enter H1 as 0 mm

Enter H2 as 250 mm

Enter T1 as -10.3 [C]

Enter T2 as -0.7 [C]

Click on Add

Change Parameters:

Enter H1 as 250 mm

Enter H2 as 500 mm

Enter T1 as -0.7 [C]

Enter T2 as 0 [C]

Click on Add

Change Parameters:

Enter H1 as 2500 mm

Enter H2 as 2750 mm

Enter T1 as 0 [C]

Enter T2 as -0.8 [C]

Click on Add

4

5

Note: An insertion point is used as a point of reference for the tendon profile in the Global Coordinate System (GCS).

Only one profile is needed for a precast beam in spite of the number of elements (four in this example) that we are

using to model it.

6 6

4

3

2

1

5

Procedure

6-11 Load Definition – Assigning Negative Temperature Differences (Beam Section Temperature)

06](https://image.slidesharecdn.com/3pscboxbridgesinglespan-241018000504-50a634e5/85/PSC-Box-Bridge-Single-Span-for-structural-engineers-53-320.jpg)

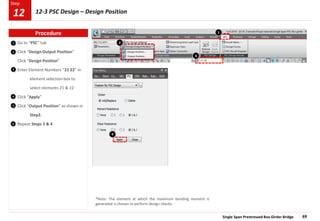

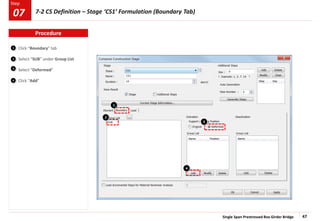

![Single Span Prestressed Box Girder Bridge 54

Step

Step

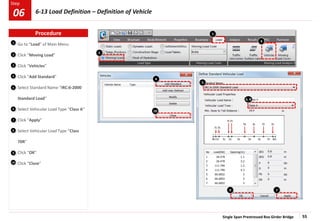

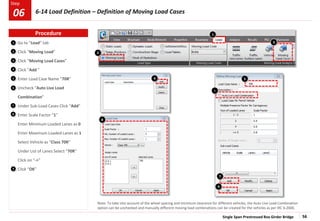

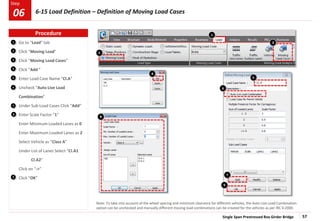

Change unit system [kN , m]

Go to “Load” tab

Click “Moving Load”

Moving Load Code > India

Click “Traffic Line Lanes”

Click “Add”

Enter Lane Name “70R”

View the figure provided

Enter Eccentricity “1.155”m

Enter Wheel Spacing “1.93”m

Enter Impact factor “0.1”

Select Vehicular Load Distribution as

“Lane Element”

Select Moving direction as “Both”

Select Selection by “2 Points”

Click in the “Box”

Click on extreme left node of

superstructure i.e. node no. 1

Click on extreme right node of

superstructure i.e. node no. 44

Click “OK”

3

7

1

Node: 1 Node: 44

6

6

7

1

2

3

4

5

2

Procedure

6-12 Load Definition – Definition of Traffic Line Lanes

06

5 6

For other lanes, similarly change names,

wheel spacing and eccentricities as

below:

Enter Lane Name “Cl.A 1”

Enter Eccentricity “2.45”m

Enter Wheel Spacing “1.8”m

Enter Impact factor “0.1”

Enter Lane Name “Cl.A 2”

Enter Eccentricity “-1.05”m

Enter Wheel Spacing “1.8”m

Enter Impact factor “0.1”

4](https://image.slidesharecdn.com/3pscboxbridgesinglespan-241018000504-50a634e5/85/PSC-Box-Bridge-Single-Span-for-structural-engineers-54-320.jpg)

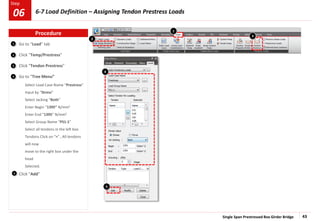

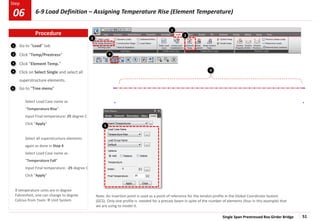

![Single Span Prestressed Box Girder Bridge 61

Step

Step

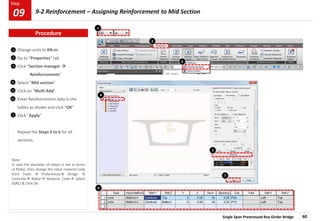

1

2

Select “Mid section”

Click on “Shear Reinforcement”

Enter Shear Reinforcement data

under “Diagonal Reinforcement” as

Pitch: 0.15m

Angle: 90 [deg]

Aw: 0.0012568 m^2 (4Legs of P20)

Enter Torsional Reinforcement data

under “Torsional Reinforcement” as

Pitch: 0.15m

Awt: 0.0003142 m^2 (1Leg of P20)

Alt: 0.008044 m^2(40 Nos. of P16)

Click “Apply”

Repeat the Steps 2 to 5 for all

sections.

Click “Close”

3

1

4

2

5

3

4

7

5

6

*Note: Diameter & number of rebars can be entered by clicking …

*

*

*

Procedure

9-3 Reinforcement – Assigning Reinforcement to Mid Section

09

7](https://image.slidesharecdn.com/3pscboxbridgesinglespan-241018000504-50a634e5/85/PSC-Box-Bridge-Single-Span-for-structural-engineers-61-320.jpg)