The document provides technical information on the Proline ProMag W 800 electromagnetic flowmeter, which is designed for demanding water and wastewater applications. It highlights features such as long battery life, maintenance-free operation, and a robust sensor with corrosion protection. Additionally, it outlines communication capabilities and compliance with international standards for custody transfer and drinking water approval.

![Proline Promag W 800

Endress+Hauser 19

Performance characteristics

Reference operating

conditions

To DIN EN 29104

• Fluid temperature: (+28 ± 2) °C / (+82 ± 4) °F

• Ambient temperature range: (+22 ± 2) °C / (+72 ± 4) °F

• Warm-up period: 30 minutes

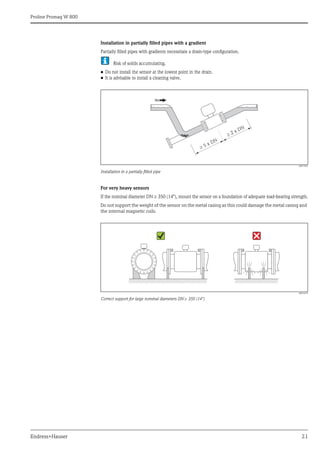

Installation conditions

• Inlet run > 10 × DN

• Outlet run > 5 × DN

• Sensor and transmitter grounded.

• The sensor is centered in the pipe.

The minimum conductivity information refers to measured value acquisition with the "CONT.PWR"

profile (continuous operation, the device records the maximum number of measured values, parameter

Prof., MPROF). Values can deviate if another profile is selected for measured value acquisition.

No special requirements must be observed at the inlet and outlet runs to keep within the in-

service maximum permissible errors for custody transfer.

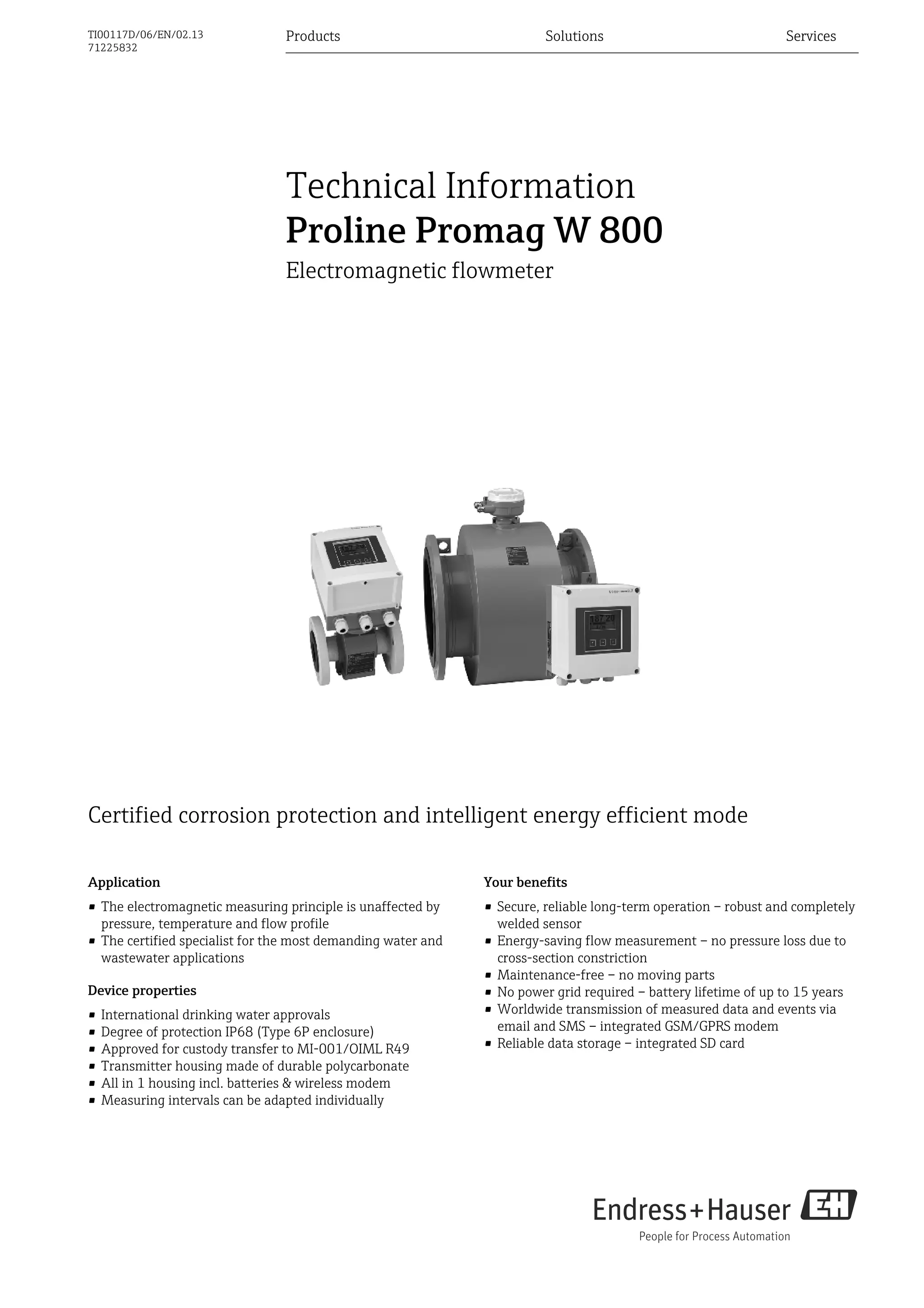

Maximum measured error Pulse output

±0.5% o.r. ± 2 mm/s (±0.5% o.r. ± 0.08 in/s)

o.r. = of reading

Fluctuations in the power supply do not have any effect within the specified range.

A0003200

Max. measured error in % of reading

Repeatability Max. ±0.2% o.r. ± 2.0 mm/s (±0.2% o.r. ± 0.08 in/s)

o.r. = of reading

2.5

[%]

2.0

1.5

1.0

0.5

0

0.5 %

0 1 2 4 6 8 10 [m/s]

v

5 10 15 20 25 30 32 [ft/s]

0](https://image.slidesharecdn.com/prolinepromagw800-endresshauserdatasheet-electromagneticflowmeter-210818172853/85/Proline-promag-w-800-endress-hauser-datasheet-electromagnetic-flowmeter-19-320.jpg)

![Proline Promag W 800

24 Endress+Hauser

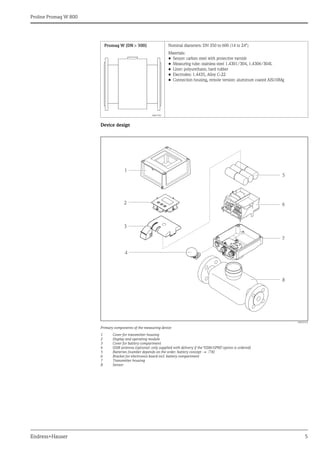

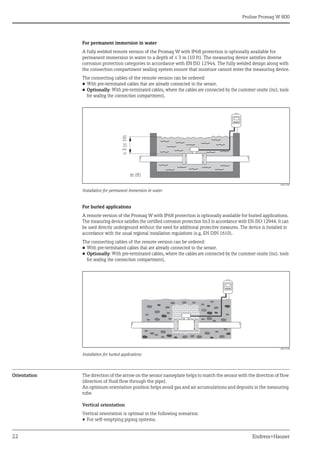

Adapters Suitable adapters to DIN EN 545 (double-flange reducers) can be used to install the sensor in larger-diameter

pipes.

The resultant increase in the rate of flow improves measuring accuracy with very slow-moving fluids. The

nomogram shown here can be used to calculate the pressure loss caused by reducers and expanders.

The nomogram only applies to liquids of viscosity similar to water.

Determining the pressure loss:

1. Calculate the ratio of the diameters d/D.

2. From the nomogram read off the pressure loss as a function of flow velocity (downstream from the

reduction) and the d/D ratio.

A0016359

Pressure loss due to adapters

Length of connecting cable The maximum connecting cable length is 20 m (35.6 ft).

When mounting the remote version, please note the following to achieve correct measuring results:

• Fix the cable run or route it in an armored conduit. Cable movements can falsify the measuring signal

especially in the case of low fluid conductivities.

• Route the cable well clear of electrical machines and switching elements.

• Ensure potential equalization between sensor and transmitter, if necessary.

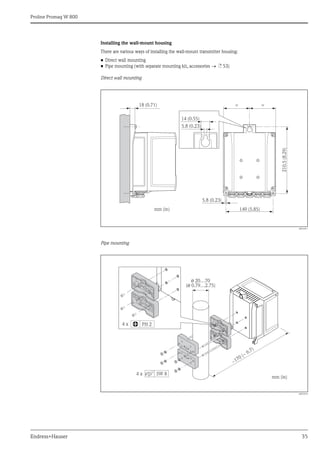

Special installation Display protection

To ensure that the optional display protection can be easily opened, maintain the following minimum head

clearance: 350 mm (13.8 in)

100

10

0.5

d / D

[mbar]

0.6 0.7 0.8 0.9

1 m/s

2 m/s

3 m/s

4 m/s

5 m/s

6 m/s

7 m/s

8 m/s

1

D

d

max. 8°](https://image.slidesharecdn.com/prolinepromagw800-endresshauserdatasheet-electromagneticflowmeter-210818172853/85/Proline-promag-w-800-endress-hauser-datasheet-electromagnetic-flowmeter-24-320.jpg)

![Proline Promag W 800

26 Endress+Hauser

Vibration resistance Acceleration up to 2 g following IEC 600 68-2-6

Mechanical load Transmitter housing

• The transmitter housing must be protected against mechanical effects, such as shock, impact etc.

It is sometimes preferable to use the remote device version.

• The transmitter housing must never be used as a ladder or climbing aid!

Electromagnetic

compatibility (EMC)

In accordance with IEC/EN 61326

GSM/GPRS signal strength It is important to ensure that the signal of the mobile communications network is strong enough to enable the

system to dial into the GPRS/GSM network.

Process

Medium temperature range Sensor

The permissible temperature depends on the lining of the measuring tube.

• –20 to +50 °C (–4 to +122 °F) for polyurethane, DN 25 to 600 (1 to 24")

• 0 to +80 °C (+32 to +176 °F) for hard rubber, DN 50 to 600 (2 to 24")

Conductivity The minimum conductivity is 50 μS/cm.

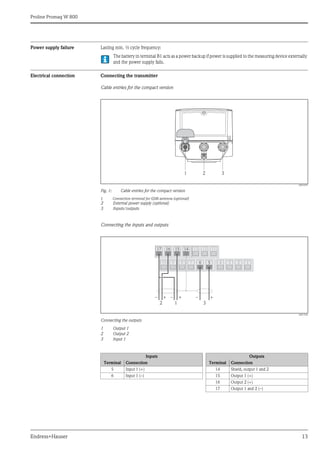

Pressure-temperature ratings The following material load diagrams refer to the entire device and not just the process connection.

Flange connection according to EN 1092-1 (DIN 2501)

A0005594

PN 6/10/16/25/40, materials C22, FE 410W B and S235JRG2, DN 25 to 600 (1 to 24")

PN25

PN16

PN10

PN 6

PN40

0

5

10

15

20

25

35

30

40

[bar]

[psi]

-60 -40 -20 0 20 40 60 80 100 120 140 160 180 [°C]

360 [°F]

0

-40 100 200 300

200

100

400

300

500

600

0](https://image.slidesharecdn.com/prolinepromagw800-endresshauserdatasheet-electromagneticflowmeter-210818172853/85/Proline-promag-w-800-endress-hauser-datasheet-electromagnetic-flowmeter-26-320.jpg)

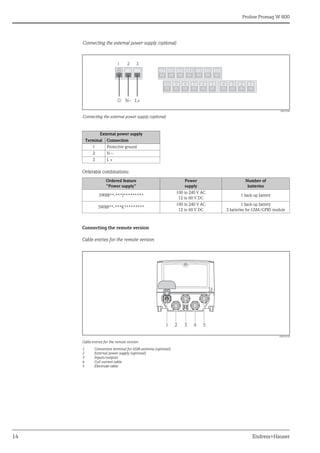

![Proline Promag W 800

Endress+Hauser 27

Flange connection according to EN 1092-1 (DIN 2501)

A0005304

PN 6/10/16/25/40, materials 1.4571/316L, DN 25 to 600 (1 to 24")

Flange connection according to ASME B16.5

A0003226

Class 150/300, materials A 105, DN 25 to 600 (1 to 24")

Flange connection according to ASME B16.5

A0005307

Class 150/300, materials F316L, DN 25 to 600 (1 to 24")

PN25

PN16

PN10

PN40

PN 6

0

5

10

15

20

25

35

30

40

[bar]

[psi]

-60 -40 -20 0 20 40 60 80 100 120 140 160 180 [°C]

360 [°F]

0

-40 100 200 300

200

100

400

300

500

600

0

Class300

Class150

0

10

20

30

40

50

[bar]

[psi]

-40 -20 0 20 40 60 80 100 120 140 160 180 [°C]

360 [°F]

0

-40 100 200 300

200

100

400

300

500

600

700

800

900

0

60

Class300

Class150

0

10

20

30

40

50

[bar]

[psi]

-40 -20 0 20 40 60 80 100 120 140 160 180 [°C]

360 [°F]

0

-40 100 200 300

200

100

400

300

500

600

700

800

900

0

60](https://image.slidesharecdn.com/prolinepromagw800-endresshauserdatasheet-electromagneticflowmeter-210818172853/85/Proline-promag-w-800-endress-hauser-datasheet-electromagnetic-flowmeter-27-320.jpg)

![Proline Promag W 800

28 Endress+Hauser

Flange connection according to JIS B2220

A0003228

10K/20K, materials HII, S235JRG2 and 1.0425/316L, DN 25 to 300 (1 to 12")

Flange connection according to AS 2129 and AS 4087

A0005595

Table E, materials A105, S235JRG2 and S275JR, DN 50 to 600 (2 to 48");

PN 16, materials A105, S275JR, DN 50 to 600 (2 to 48")

Pressure tightness Liner: polyurethane, hard rubber

Limiting flow The diameter of the pipe and the flow rate determine the nominal diameter of the sensor. The optimum velocity

of flow is between 2 and 3 m/s (6.56 to 9.84 ft/s). Also match the velocity of flow (v) to the physical properties

of the fluid:

• v < 2 m/s (v < 6.5 ft/s): for abrasive fluids (potter's clay, lime milk, ore slurry etc.)

• v > 2 m/s (v > 6.5 ft/s): for fluids producing buildup (wastewater sludge etc.)

10K

20K

-40 -20 0 20 40 60 80 100 120 140 160 180 [°C]

0

10

20

30

[bar]

360 [°F]

0

-40 100 200 300

[psi]

200

100

400

300

0

-40 -20 0 20 40 60 80 100 120 140 160 [°C]

0

10

5

20

15

[bar]

0

-40 100 200 300 [°F]

[psi]

200

100

300

0

TableE

PN16

Promag W

Nominal diameter

Measuring

tube liner

Liner pressure tightness: limit values for

absolute pressure at different fluid temperatures

[mm] [in]

25 °C (77 °F) 50 °C (122 °F) 80 °C (176 °F)

[mbar]/[psi] [mbar]/[psi] [mbar]/[psi]

25 to 600 1 to 24" Polyurethane 0 0 -

50 to 600 2 to 24" Hard rubber 0 0 0](https://image.slidesharecdn.com/prolinepromagw800-endresshauserdatasheet-electromagneticflowmeter-210818172853/85/Proline-promag-w-800-endress-hauser-datasheet-electromagnetic-flowmeter-28-320.jpg)

![Proline Promag W 800

Endress+Hauser 29

Flow characteristic values in SI units

Flow characteristic values in US units

Nominal

diameter

Recommended

flow

min./max. full scale value

Factory setting

Full scale value Pulse value

approx. 2 pulse/s

for

Low flow cut off

[mm] (v 0.5 or 10 m/s) (v 2.5 m/s) (v 2.5 m/s) (v 0.04 m/s)

25 15 to 295 dm³/min 75 dm3/min 0.03 dm3 2 dm3/min

32 25 to 485 dm³/min 125 dm3/min 0.05 dm3 4 dm3/min

40 40 to 755 dm³/min 200 dm3/min 0.08 dm3 6 dm3/min

50 60 to 1180 dm³/min 300 dm3/min 0.10 dm3 10 dm3/min

65 100 to 2000 dm³/min 500 dm3/min 0.20 dm3 15 dm3/min

80 150 to 3020 dm³/min 750 dm3/min 0.30 dm3 20 dm3/min

100 240 to 4750 dm³/min 1200 dm3/min 0.50 dm3 40 dm3/min

125 370 to 7400 dm³/min 1850 dm3/min 0.75 dm3 60 dm3/min

150 32 to 640 m³/h 150 m3/h 0.001 m3 5 m3/h

200 58 to 1135 m³/h 300 m3/h 0.002 m3 10 m3/h

250 90 to 1800 m³/h 500 m3/h 0.003 m3 15 m3/h

300 130 to 2500 m³/h 750 m3/h 0.004 m3 20 m3/h

350 175 to 3500 m³/h 1000 m3/h 0.006 m3 25 m3/h

375 200 to 4000 m³/h 1200 m3/h 0.008 m3 35 m3/h

400 226 to 4600 m³/h 1200 m3/h 0.008 m3 35 m3/h

450 286 to 5800 m³/h 1500 m3/h 0.010 m3 40 m3/h

500 353 to 7100 m³/h 2000 m3/h 0.012 m3 50 m3/h

600 510 to 10200 m³/h 2500 m3/h 0.017 m3 80 m3/h

Nominal

diameter

Recommended

flow

min./max. full scale value

Factory setting

Full scale value Pulse value

approx. 2 pulse/s

for

Low flow cut off

[in] (v 0.5 or 10 m/s) (v 2.5 m/s) (v 2.5 m/s) (v 0.04 m/s)

1" 4 to 80 gal/min 20 gal/min 0.008 gal 0.60 gal/min

– 7 to 130 gal/min 30 gal/min 0.015 gal 1.00 gal/min

1 /" 10 to 200 gal/min 50 gal/min 0.02 gal 1.50 gal/min

2" 16 to 320 gal/min 80 gal/min 0.03 gal 2.50 gal/min

2 ½" 28 to 530 gal/min 150 gal/min 0.05 gal 4.00 gal/min

3" 40 to 800 gal/min 200 gal/min 0.08 gal 6.00 gal/min

4" 65 to 1200 gal/min 300 gal/min 0.15 gal 10.0 gal/min

5" 100 to 1900 gal/min 500 gal/min 0.20 gal 15.0 gal/min

6" 142 to 2800 gal/min 700 gal/min 0.30 gal 20.0 gal/min

8" 250 to 4900 gal/min 1200 gal/min 0.50 gal 40.0 gal/min

10" 390 to 7700 gal/min 2000 gal/min 0.80 gal 60.0 gal/min

12" 570 to 11000 gal/min 3000 gal/min 1.15 gal 80.0 gal/min

14" 770 to 15000 gal/min 4000 gal/min 1.50 gal 115.0 gal/min

15" 880 to 17000 gal/min 5000 gal/min 2.00 gal 150.0 gal/min

16" 1000 to 19000 gal/min 5000 gal/min 2.00 gal 150.0 gal/min

18" 1265 to 25000 gal/min 6500 gal/min 2.50 gal 200.0 gal/min

20" 1600 to 30000 gal/min 7500 gal/min 3.00 gal 250.0 gal/min

24" 2250 to 44000 gal/min 12000 gal/min 5.00 gal 350.0 gal/min](https://image.slidesharecdn.com/prolinepromagw800-endresshauserdatasheet-electromagneticflowmeter-210818172853/85/Proline-promag-w-800-endress-hauser-datasheet-electromagnetic-flowmeter-29-320.jpg)

![Proline Promag W 800

Endress+Hauser 31

Mechanical construction

Design, dimensions Compact version DN 25 to 300 (1 to 12")

A0017392

Dimensions in SI units

Dimensions in US units

DN1)

L2)

A B C D E F G H J K

[mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm]

25 200 216 189 120 165 157 269 353 84 94 182

32 200 216 189 120 165 157 269 353 84 94 182

40 200 216 189 120 165 157 269 353 84 94 182

50 200 216 189 120 165 157 269 353 84 94 182

65 200 216 189 180 165 157 294 403 109 94 182

80 200 216 189 180 165 157 294 403 109 94 182

100 250 216 189 180 165 157 294 403 109 94 182

125 250 216 189 260 165 157 334 484 150 140 182

150 300 216 189 260 165 157 334 484 150 140 182

200 350 216 189 324 165 157 359 539 180 156 182

250 450 216 189 400 165 157 384 589 205 156 182

300 500 216 189 460 165 157 409 639 230 166 182

1)

EN (DIN), AS, JIS: For flanges according to AS, only nominal diameters DN 80, 100 and 150 to 300 are available.

2) The length is independent of the selected pressure rating. Length in accordance with DVGW/ISO.

DN1) L2) A B C D E F G H J K

[in] [in] [in] [in] [in] [in] [in] [in] [in] [in] [in] [in]

1" 7.87 8.50 7.44 4.72 6.50 6.18 10.59 13.90 3.32 3.70 7.17

1½" 7.87 8.50 7.44 4.72 6.50 6.18 10.59 13.90 3.32 3.70 7.17

2" 7.87 8.50 7.44 4.72 6.50 6.18 10.59 13.90 3.32 3.70 7.17

3" 7.87 8.50 7.44 7.10 6.50 6.18 11.57 15.87 4.30 3.70 7.17

4" 9.84 8.50 7.44 7.10 6.50 6.18 11.57 15.87 4.30 3.70 7.17

6" 11.8 8.50 7.44 10.2 6.50 6.18 13.15 19.06 5.91 5.51 7.17

8" 13.8 8.50 7.44 12.8 6.50 6.18 14.13 21.22 7.10 6.14 7.17

10" 17.7 8.50 7.44 15.8 6.50 6.18 15.12 23.19 8.08 6.14 7.17

12" 19.7 8.50 7.44 18.1 6.50 6.18 16.10 25.16 9.06 6.54 7.17

1)

ASME

2) The length is independent of the selected pressure rating. Length in accordance with DVGW/ISO.

A

C

B

L

H

J

F

G

E

D

K](https://image.slidesharecdn.com/prolinepromagw800-endresshauserdatasheet-electromagneticflowmeter-210818172853/85/Proline-promag-w-800-endress-hauser-datasheet-electromagnetic-flowmeter-31-320.jpg)

![Proline Promag W 800

32 Endress+Hauser

Compact version DN 350 to 600 (14 to 24")

A0017394

Dimensions in SI units

Dimensions in US units

DN1)

L2)

A B C D E F G H J K

[mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm]

350 550 216 189 564 165 157 478.5 760.5 282.0 276 192

375 600 216 189 616 165 157 504.5 812.5 308.0 276 192

400 600 216 189 616 165 157 504.5 812.5 308.0 276 192

450 650 216 189 666 165 157 529.5 862.5 333.0 292 192

500 650 216 189 717 165 157 555.0 913.5 358.5 292 192

600 780 216 189 821 165 157 607.0 1017.5 410.5 402 192

1)

EN (DIN), AS: For flanges according to AS, only nominal diameters DN 350, 400, 500 and 600 are available.

2)

The length is independent of the selected pressure rating. Length in accordance with DVGW/ISO.

DN1)

L2)

A B C D E F G H J K

[in] [in] [in] [in] [in] [in] [in] [in] [in] [in] [in] [in]

14" 21.6 8.50 7.44 22.2 6.50 6.18 18.84 29.94 11.1 10.9 7.56

15" 23.6 8.50 7.44 24.2 6.50 6.18 19.86 31.99 12.1 10.9 7.56

16" 23.6 8.50 7.44 24.2 6.50 6.18 19.86 31.99 12.1 10.9 7.56

18" 25.6 8.50 7.44 26.2 6.50 6.18 20.85 33.96 13.1 11.5 7.56

20" 25.6 8.50 7.44 28.2 6.50 6.18 21.85 35.96 14.1 11.5 7.56

24" 30.7 8.50 7.44 32.3 6.50 6.18 23.90 40.06 16.2 15.8 7.56

1)

ASME

2) The length is independent of the selected pressure rating. Length in accordance with DVGW/ISO.

L

C

E

F

J

G

A

B

H

D

K](https://image.slidesharecdn.com/prolinepromagw800-endresshauserdatasheet-electromagneticflowmeter-210818172853/85/Proline-promag-w-800-endress-hauser-datasheet-electromagnetic-flowmeter-32-320.jpg)

![Proline Promag W 800

Endress+Hauser 33

Compact version DN 350 to 600 (14 to 24")

Order code for "Design", option A "Insertion length short"

A0021031

Dimensions in SI units

Dimensions in US units

DN

[mm]

L

[mm]

A

[mm]

B

[mm]

D

[mm]

E

[mm]

F

[mm]

J

[mm]

K

[mm]

350 550 216 189 165 157 433 290 192

375 600 216 189 165 157 459 290 192

400 600 216 189 165 157 459 290 192

450 600 216 189 165 157 487 290 192

500 600 216 189 165 157 512 290 192

600 600 216 189 165 157 553 290 192

DN

[mm]

Dimension C Dimension G

EN (DIN) ASME AS EN (DIN) ASME AS

PN 6

[mm]

PN 10

[mm]

PN 16

[mm]

AWWA

[mm] [mm]

PN 6

[mm]

PN 10

[mm]

PN 16

[mm]

AWWA

[mm] [mm]

350 490 505 520 533 525 678 685 693 700 696

375 – – – – 550 – – – – 734

400 540 565 580 597 580 729 741 649 757 749

450 595 615 640 635 640 784 794 807 804 807

500 645 670 715 699 705 834 847 870 861 864

600 755 780 840 813 825 930 943 973 959 965

DN

[in]

L

[in]

A

[in]

B

[in]

D

[in]

E

[in]

F

[in]

J

[in]

K

[in]

14 21.6 8.50 7.44 6.50 6.18 17.1 11.4 7.56

15 23.6 8.50 7.44 6.50 6.18 18.1 11.4 7.56

16 23.6 8.50 7.44 6.50 6.18 18.1 11.4 7.56

18 23.6 8.50 7.44 6.50 6.18 19.2 11.4 7.56

20 23.6 8.50 7.44 6.50 6.18 20.2 11.4 7.56

24 23.6 8.50 7.44 6.50 6.18 21.8 11.4 7.56

L

C

E

F

J

G

A

B

D

K](https://image.slidesharecdn.com/prolinepromagw800-endresshauserdatasheet-electromagneticflowmeter-210818172853/85/Proline-promag-w-800-endress-hauser-datasheet-electromagnetic-flowmeter-33-320.jpg)

![Proline Promag W 800

34 Endress+Hauser

Transmitter remote version, wall-mount housing

"Housing" order feature, option N: remote, polycarbonate

A0017347

Dimensions in SI units

Dimensions in US units

DN

[in]

Dimension C Dimension G

EN (DIN) ASME AS EN (DIN) ASME AS

PN 6

[in]

PN 10

[in]

PN 16

[in]

AWWA

[in] [in]

PN 6

[in]

PN 10

[in]

PN 16

[in]

AWWA

[in] [in]

14 19.3 19.9 20.5 21.0 20.7 26.7 27.0 27.3 27.6 27.4

15 – – – – 21.7 – – – – 28.9

16 21.3 22.2 22.8 23.5 22.8 28.7 29.2 29.5 29.8 29.5

18 23.4 24.2 25.2 25.0 25.2 30.9 31.3 31.8 31.7 31.8

20 25.4 26.4 28.1 27.5 27.8 32.9 33.4 34.3 33.9 34.0

24 29.7 30.7 33.1 32.0 32.5 36.6 37.2 38.3 37.8 38.0

A B C D E F G H J K L

[mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm]

165 185 15 25 225 151.5 50 53 56 88.5 53

A B C D E F G H J K L

[in] [in] [in] [in] [in] [in] [in] [in] [in] [in] [in]

6.50 7.28 0.59 0.98 8.86 5.96 1.97 2.09 2.20 3.48 2.09

B

A

K

G

H

L

J

J

C

D

E

F](https://image.slidesharecdn.com/prolinepromagw800-endresshauserdatasheet-electromagneticflowmeter-210818172853/85/Proline-promag-w-800-endress-hauser-datasheet-electromagnetic-flowmeter-34-320.jpg)

![Proline Promag W 800

36 Endress+Hauser

Remote version sensor, DN 25 to 300 (1 to 12")

A0012462

Dimensions in SI units

Dimensions in US units

DN1)

L2)

A B C D E F G H J

[mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm]

25 200

129 163 143 102

286 202 84 120 94

32 200 286 202 84 120 94

40 200 286 202 84 120 94

50 200 286 202 84 120 94

65 200 336 227 109 180 94

80 200 336 227 109 180 94

100 250 336 227 109 180 94

125 250 417 267 150 260 140

150 300 417 267 150 260 140

200 350 472 292 180 324 156

250 450 522 317 205 400 156

300 500 572 342 230 460 166

1)

EN (DIN), AS, JIS: For flanges according to AS, only nominal diameters DN 80, 100 and 150 to 300 are available.

2)

The length is independent of the selected pressure rating. Length in accordance with DVGW/ISO.

DN1)

L2)

A B C D E F G H J

[in] [in] [in] [in] [in] [in] [in] [in] [in] [in] [in]

1" 7.87

5.08 6.42 5.63 4.02

11.3 7.95 3.32 4.72 3.70

1½" 7.87 11.3 7.95 3.32 4.72 3.70

2" 7.87 11.3 7.95 3.32 4.72 3.70

3" 7.87 13.2 8.94 4.30 7.10 3.70

4" 9.84 13.2 8.94 4.30 7.10 3.70

6" 11.8 16.4 10.5 5.91 10.2 5.51

8" 13.8 18.6 11.5 7.10 12.8 6.14

10" 17.7 20.6 12.5 8.08 15.8 6.14

12" 19.7 22.5 13.5 9.06 18.1 6.54

1)

ASME

2) The length is independent of the selected pressure rating. Length in accordance with DVGW/ISO.

J

L

E

G

F

H

B

C

A

D](https://image.slidesharecdn.com/prolinepromagw800-endresshauserdatasheet-electromagneticflowmeter-210818172853/85/Proline-promag-w-800-endress-hauser-datasheet-electromagnetic-flowmeter-36-320.jpg)

![Proline Promag W 800

Endress+Hauser 37

Remote version sensor, DN 50 to 300 (2 to 12"), fully welded (IP68)

A0017206

Dimensions in SI units

DN L A B D F

[mm] [mm] [mm] [mm] [mm] [mm]

50 200

112 138 95.5

189.0

65 200 201.5

80 200 206.5

100 250 219.0

125 250 232.0

150 300 253.5

200 350 279.0

250 450 312.5

300 500 337.5

DN E for pressure ratings

EN (DIN) ASME AS JIS

PN 10 PN 16 PN 25 PN 40 Class

150

Class

300

Table E PN 16 10K 20K

[mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm]

50 – – – 272 265 272 264 264 267 267

65 – 295 – 295 – – – – 290 290

80 – 307 – 307 302 311 300 300 300 307

100 – 330 – 382 333 346 327 327 325 332

125 – 357 – 367 – – – – 357 367

150 – 396 – 404 393 412 395 395 395 406

200 450 450 460 – 450 – 447 447 445 454

250 510 515 525 – 516 – 515 515 513 528

300 560 568 580 – 580 – 565 565 560 578

DN H for pressure ratings

EN (DIN) ASME AS JIS

PN 10 PN 16 PN 25 PN 40 Class

150

Class

300

Table E PN 16 10K 20K

[mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm]

50 – – – 165 152.4 165.0 150 150 155 155

65 – 185 – 185 – – – – 175 175

80 – 200 – 200 190.5 209.6 185 185 185 200

100 – 220 – 325 228.6 254.0 215 215 210 225

125 – 250 – 270 – – – – 250 270

H

B

A

D

L

F

E](https://image.slidesharecdn.com/prolinepromagw800-endresshauserdatasheet-electromagneticflowmeter-210818172853/85/Proline-promag-w-800-endress-hauser-datasheet-electromagnetic-flowmeter-37-320.jpg)

![Proline Promag W 800

38 Endress+Hauser

Dimensions in US units

150 – 285 – 300 279.4 317.5 280 280 280 305

200 340 340 360 – 342.9 – 335 335 330 350

250 395 405 425 – 406.4 – 405 405 400 430

300 445 460 485 – 482.6 – 455 455 445 480

DN L A B D F

[in] [in] [in] [in] [in] [in]

2" 7.78

4.41 5.43 3.76

7.44

3" 7.78 8.13

4" 9.84 8.62

6" 11.8 9.98

8" 13.8 11.0

10" 17.7 12.3

12" 19.7 13.3

DN E for pressure ratings

EN (DIN) ASME AS JIS

PN 10 PN 16 PN 25 PN 40 Class

150

Class

300

Table E PN 16 10K 20K

[in] [in] [in] [in] [in] [in] [in] [in] [in] [in] [in]

2" – – – 10.69 10.44 10.69 10.39 10.39 10.49 10.49

3" – 12.07 – 12.07 11.88 12.26 11.81 11.81 11.81 12.07

4" – 12.99 – 15.02 13.12 13.62 12.85 12.85 12.80 13.05

6" – 15.59 – 15.89 15.48 16.23 15.55 15.55 15.55 15.98

8" 17.72 17.72 18.11 – 17.73 – 17.58 17.58 17.52 17.87

10" 20.08 20.28 20.67 – 20.30 – 20.28 20.28 20.18 20.77

12" 22.05 22.34 22.83 – 22.83 – 22.24 22.24 22.05 22.74

DN H for pressure ratings

EN (DIN) ASME AS JIS

PN 10 PN 16 PN 25 PN 40 Class

150

Class

300

Table E PN 16 10K 20K

[in] [in] [in] [in] [in] [in] [in] [in] [in] [in] [in]

2" – – – 6.50 6.00 6.50 5.91 5.91 6.10 6.10

3" – 7.78 – 7.78 7.50 8.25 7.28 7.28 7.28 7.78

4" – 8.66 – 12.8 9.00 10.0 8.46 8.46 8.27 8.86

6" – 11.2 – 11.8 11.0 12.5 11.0 11.0 11.0 12.0

8" 13.4 13.4 14.2 – 13.5 – 13.2 13.2 13.0 13.8

10" 15.6 15.9 16.7 – 16.0 – 15.9 15.9 15.8 16.9

12" 17.5 18.1 19.1 – 19.0 – 17.9 17.9 17.5 18.9

DN H for pressure ratings

EN (DIN) ASME AS JIS

PN 10 PN 16 PN 25 PN 40 Class

150

Class

300

Table E PN 16 10K 20K

[mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm]](https://image.slidesharecdn.com/prolinepromagw800-endresshauserdatasheet-electromagneticflowmeter-210818172853/85/Proline-promag-w-800-endress-hauser-datasheet-electromagnetic-flowmeter-38-320.jpg)

![Proline Promag W 800

Endress+Hauser 39

Remote version sensor, DN 350 to 600 (14 to 24")

A0003220

Dimensions in SI units

Dimensions in US units

DN1) L2) A B C D E F G H J

[mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm]

350 550

129 163 143 102

683.5 401.5 282.0 564 276

375 600 735.5 427.5 308.0 616 276

400 600 735.5 427.5 308.0 616 276

450 650 785.5 452.5 333.0 666 292

500 650 836.5 478.0 358.5 717 292

600 780 940.5 530.0 410.5 821 402

1) EN (DIN), AS: For flanges according to AS, only nominal diameters DN 350, 400, 500 and 600 are available.

2)

The length is independent of the selected pressure rating. Length in accordance with DVGW/ISO.

DN1)

L2)

A B C D E F G H J

[mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm]

14" 21.6

5.08 6.42 5.63 4.02

29.1 15.8 11.1 22.2 10.9

15" 23.6 31.1 16.8 12.1 24.2 10.9

16" 23.6 31.1 16.8 12.1 24.2 10.9

18" 25.6 33.1 17.8 13.1 26.2 11.5

20" 25.6 35.1 18.8 14.1 28.2 11.5

24" 30.7 39.1 20.9 16.2 32.3 15.8

1)

ASME

2) The length is independent of the selected pressure rating. Length in accordance with DVGW/ISO.

H

E

G

F

L

J

A B

C

D](https://image.slidesharecdn.com/prolinepromagw800-endresshauserdatasheet-electromagneticflowmeter-210818172853/85/Proline-promag-w-800-endress-hauser-datasheet-electromagnetic-flowmeter-39-320.jpg)

![Proline Promag W 800

40 Endress+Hauser

Remote version sensor, DN 350 to 600 (14 to 24")

Order code for "Design", option A "Insertion length short"

A0017284

Dimensions in SI units

Dimensions in US units

DN

[mm]

A

[mm]

B

[mm]

E

[mm]

F

[mm]

350 129 353 290 550

375 129 379 290 600

400 129 379 290 600

450 129 407 290 600

500 129 432 290 600

600 129 473 290 600

DN

[mm]

Dimension C Dimension D

EN (DIN) ASME AS EN (DIN) ASME AS

PN 6

[mm]

PN 10

[mm]

PN 16

[mm]

AWWA

[mm] [mm]

PN 6

[mm]

PN 10

[mm]

PN 16

[mm]

AWWA

[mm] [mm]

350 598 605 613 620 615 490 505 520 533 525

375 – – – – 654 – – – – 550

400 649 661 669 677 669 540 565 580 597 580

450 704 714 727 724 727 595 615 640 635 640

500 754 767 790 781 784 645 670 715 699 705

600 850 863 893 879 885 755 780 840 813 825

DN

[in]

A

[in]

B

[in]

E

[in]

F

[in]

14 5.08 13.9 11.4 21.6

15 5.08 14.9 11.4 23.6

16 5.08 14.9 11.4 23.6

18 5.08 16.0 11.4 23.6

20 5.08 17.0 11.4 23.6

24 5.08 18.6 11.4 23.6

D F

E

B

C

A](https://image.slidesharecdn.com/prolinepromagw800-endresshauserdatasheet-electromagneticflowmeter-210818172853/85/Proline-promag-w-800-endress-hauser-datasheet-electromagnetic-flowmeter-40-320.jpg)

![Proline Promag W 800

Endress+Hauser 41

Remote version sensor, DN 350 to 600 (14 to 24")

Order code for "Design", option A "Insertion length short"

Order code for "Sensor option", option CA to CE "Corrosion protection"

A0020962

Dimensions in SI units

DN

[in]

Dimension C Dimension D

EN (DIN) ASME AS EN (DIN) ASME AS

PN 6

[in]

PN 10

[in]

PN 16

[in]

AWWA

[in] [in]

PN 6

[in]

PN 10

[in]

PN 16

[in]

AWWA

[in] [in]

14 23.5 23.8 24.1 24.4 24.2 19.3 19.9 20.5 21.0 20.7

15 – – – – 25.7 – – – – 21.7

16 25.6 26.0 26.3 26.7 26.3 21.3 22.2 22.8 23.5 22.8

18 27.7 28.1 28.6 28.5 28.6 23.4 24.2 25.2 25.0 25.2

20 29.7 30.2 31.1 30.7 30.9 25.4 26.4 28.1 27.5 27.8

24 33.5 34.0 35.2 34.6 34.8 29.7 30.7 33.1 32.0 32.5

DN

[mm]

A

[mm]

B

[mm]

E

[mm]

F

[mm]

350 112 350 290 550

375 112 376 290 600

400 112 376 290 600

450 112 403 290 600

500 112 428 290 600

600 112 478 290 600

DN

[mm]

Dimension C Dimension D

EN (DIN) AWWA AS EN (DIN) AWWA AS

PN 6

[mm]

PN 10

[mm]

PN 16

[mm] [mm] [mm]

PN 6

[mm]

PN 10

[mm]

PN 16

[mm] [mm] [mm]

350 595 603 610 – 613 490 505 520 – 525

375 – – – – 651 – – – – 550

400 646 659 666 – 666 540 565 580 – 580

450 701 711 723 – 723 595 615 640 – 640

D F

E

B

C

A](https://image.slidesharecdn.com/prolinepromagw800-endresshauserdatasheet-electromagneticflowmeter-210818172853/85/Proline-promag-w-800-endress-hauser-datasheet-electromagnetic-flowmeter-41-320.jpg)

![Proline Promag W 800

42 Endress+Hauser

Dimensions in US units

500 751 763 786 – 781 645 670 715 – 705

600 856 868 898 – 891 755 780 840 – 825

DN

[in]

A

[in]

B

[in]

E

[in]

F

[in]

14 4.41 13.8 11.4 21.6

15 4.41 14.8 11.4 23.6

16 4.41 14.8 11.4 23.6

18 4.41 15.9 11.4 23.6

20 4.41 16.9 11.4 23.6

24 4.41 18.8 11.4 23.6

DN

[in]

Dimension C Dimension D

EN (DIN) AWWA AS EN (DIN) AWWA AS

PN 6

[in]

PN 10

[in]

PN 16

[in] [in] [in]

PN 6

[in]

PN 10

[in]

PN 16

[in] [in] [in]

14 23.4 23.7 24.0 – 24.1 19.3 19.9 20.5 – 20.7

15 – – – – 25.6 – – – – 21.7

16 25.4 25.9 26.2 – 26.2 21.3 22.2 22.8 – 22.8

18 27.6 28.0 28.5 – 28.5 23.4 24.2 25.2 – 25.2

20 29.6 30.0 30.9 – 30.7 25.4 26.4 28.1 – 27.8

24 33.7 34.2 35.4 – 35.1 29.7 30.7 33.1 – 32.5

DN

[mm]

Dimension C Dimension D

EN (DIN) AWWA AS EN (DIN) AWWA AS

PN 6

[mm]

PN 10

[mm]

PN 16

[mm] [mm] [mm]

PN 6

[mm]

PN 10

[mm]

PN 16

[mm] [mm] [mm]](https://image.slidesharecdn.com/prolinepromagw800-endresshauserdatasheet-electromagneticflowmeter-210818172853/85/Proline-promag-w-800-endress-hauser-datasheet-electromagnetic-flowmeter-42-320.jpg)

![Proline Promag W 800

Endress+Hauser 43

Remote version sensor, DN 350 to 600 (14 to 24")

Order code for "Design", option B "Insertion length long"

Order code for "Sensor option", option CA to CE "Corrosion protection"

A0018158

Dimensions in SI units

Dimensions in US units

DN

[mm]

L

[mm]

A

[mm]

B

[mm]

C

[mm]

D

[mm]

E

[mm]

F

[mm]

G

[mm]

H

[mm]

350 550 112 564 138 95,5 395 282 677 276

375 600 112 616 138 95,5 421 308 729 276

400 600 112 616 138 95,5 421 308 729 276

450 650 112 666 138 95,5 446 333 779 292

500 650 112 717 138 95,5 472 359 830 292

600 780 112 821 138 95,5 524 411 934 402

DN

[in]

L

[in]

A

[in]

B

[in]

C

[in]

D

[in]

E

[in]

F

[in]

G

[in]

H

[in]

14 21.6 4.41 22.2 5.43 3.76 15.6 11.1 26.7 10.9

15 23.6 4.41 24.2 5.43 3.76 16.6 12.1 28.7 10.9

16 23.6 4.41 24.2 5.43 3.76 16.6 12.1 28.7 10.9

18 25.6 4.41 26.2 5.43 3.76 17.6 13.1 30.7 11.5

20 25.6 4.41 28.2 5.43 3.76 18.6 14.1 32.7 11.5

24 30.7 4.41 32.3 5.43 3.76 20.6 16.2 36.8 15.8

L

H

G

E

B

A C

D

F](https://image.slidesharecdn.com/prolinepromagw800-endresshauserdatasheet-electromagneticflowmeter-210818172853/85/Proline-promag-w-800-endress-hauser-datasheet-electromagnetic-flowmeter-43-320.jpg)

![Proline Promag W 800

44 Endress+Hauser

Accessories

Ground disks for flange connections

A0017303

Dimensions in SI units

DN 1) EN (DIN) / JIS / AS 2)

A B D H

[mm] [mm] [mm] [mm] [mm]

25 26 62 77.5 87.5

32 35 80 87.5 94.5

40 41 82 101.0 103

50 52 101 115.5 108

65 68 121 131.5 118

80 80 131 154.5 135

100 104 156 186.5 153

125 130 187 206.5 160

150 158 217 256 184

200 206 267 288 205

250 260 328 359 240

300 3) 312 375 413 273

300 4) 310 375 404 268

350 3) 343 433 479 365

375 3) 343 433 479 365

400 3) 393 480 542 395

450 3) 439 538 583 417

500 3) 493 592 650 460

600 3)

593 693 766 522

1)

Ground disks can be used for all the flange standards/pressure ratings which can be supplied in the standard version.

2) EN (DIN), AS, JIS; For flanges according to AS, DN 32, 40, 65 and 125 are not available.

3)

PN 10/16

4)

PN 25, JIS 10K/20K

H

H

DN£ 300 (12")

t = 2 (0.08)

t = 2 (0.08)

9 (0.35)

Æ

6.5 (0.26)

Æ

B

Æ

A

Æ D

Æ

A

Æ

B

Æ

D

Æ

³

DN 350 (14")](https://image.slidesharecdn.com/prolinepromagw800-endresshauserdatasheet-electromagneticflowmeter-210818172853/85/Proline-promag-w-800-endress-hauser-datasheet-electromagnetic-flowmeter-44-320.jpg)

![Proline Promag W 800

Endress+Hauser 45

Dimensions in US units

Weight Weight in SI units

Promag W (standard)

DN1) ASME

A B D H

[in] [in] [in] [in] [in]

1" 1.02 2.44 3.05 3.44

1 ½" 1.61 3.23 3.98 4.06

2" 2.05 3.98 4.55 4.25

3" 3.15 5.16 6.08 5.31

4" 4.09 6.14 7.34 6.02

6" 6.22 8.54 10.08 7.24

8" 8.11 10.51 11.34 8.07

10" 10.24 12.91 14.13 9.45

12" 12.28 14.76 16.26 10.75

14" 13.50 17.05 18.86 14.37

15" 13.50 17.05 18.86 14.37

16" 15.47 18.90 21.34 15.55

18" 17.28 21.18 22.95 16.42

20" 19.41 23.31 25.59 18.11

24" 23.35 27.28 30.16 20.55

1) Ground disks can be used for all the flange standards/pressure ratings which can be supplied in the standard version.

Weight data of Promag W in kg (for standard pressure ratings and excluding packaging material)

Nominal

diameter

Compact version

(sensor and transmitter)

excluding batteries

Remote version

(sensor and connection housing)

excluding connecting cable, transmitter and

batteries

[mm] [in] EN (DIN) /AS* JIS ASME EN (DIN) /AS* JIS ASME

25 1"

PN

40

5.3

10K

5.3

Class

150

5.3

PN

40

5.3

10K

5.3

Class

150

5.3

32 – 6.0 5.3 – 6.0 5.3 –

40 1 ½" 7.4 6.3 7.4 7.4 6.3 7.4

50 2" 8.6 7.3 8.6 8.6 7.3 8.6

65 –

PN

16

10.0 9.1 –

PN

16

10.0 9.1 –

80 3" 12.0 10.5 12.0 12.0 10.5 12.0

100 4" 14.0 12.7 14.0 14.0 12.7 14.0

125 – 19.5 19.0 – 19.5 19.0 –

150 6" 23.5 22.5 23.5 23.5 22.5 23.5

200 8"

PN

10

43 39.9 43

PN

10

43 39.9 43

250 10" 63 67.4 63 63 67.4 73

300 12" 68 70.3 108 68 70.3 108

350 14" 113 173 113 173

400 16" 133 203 133 203

450 18" 173 253 173 253

500 20" 173 283 173 283

600 24" 233 403 233 403

Transmitter remote version = 1.5 kg

*Flanges according to AS are only available for DN 80, 100, 150 to 400, 500 and 600

Weight of battery block with: one battery = 100 g/two batteries = 190 g/three batteries = 290 g](https://image.slidesharecdn.com/prolinepromagw800-endresshauserdatasheet-electromagneticflowmeter-210818172853/85/Proline-promag-w-800-endress-hauser-datasheet-electromagnetic-flowmeter-45-320.jpg)

![Proline Promag W 800

46 Endress+Hauser

Promag W (fully welded sensor option)

Order code for "Design", option A "Insertion length short" with DN 350 to 600

Order code for "Design", option A "Insertion length short" with DN 350 to 600

Weight data of Promag W in kg (for standard pressure ratings and excluding packaging material)

Nominal

diameter

Remote version (sensor and connection housing)

excluding connecting cable, transmitter and batteries

[mm] [in] EN (DIN) /AS* JIS ASME

50 2" PN 40 10

10

K

9

Class

150

9

65 –

PN

16

11 10 –

80 3" 13 11 13

100 4" 15 13 17

125 – 20 18 –

150 6" 25 23 26

200 8"

PN

10

36 32 42

250 10" 49 48 59

300 12" 58 55 84

Transmitter remote version = 1.5 kg

*Flanges according to AS are only available for DN 50, 80, 100, 150, 200, 250 and 300.

Weight of battery block with: one battery = 100 g/two batteries = 190 g/three batteries = 290 g

Weight data of Promag W in kg (for standard pressure ratings and excluding packaging material)

Compact version (sensor and transmitter) excluding batteries

DN EN (DIN) ASME, AWWA AS

[mm] [in]

Pres-

sure

rating

[kg]

Pres-

sure

rating

[kg]

Pres-

sure

rating

[kg]

Pressure

rating [kg]

Pres-

sure

rating

[kg]

Pres-

sure

rating

[kg]

350 14 PN 6 79 PN 10 90 PN 16 105 Class 150 139 PN 16 101 Table E 101

375 15 PN 6 – PN 10 – PN 16 – Class 150 – PN 16 107 Table E –

400 16 PN 6 91 PN 10 106 PN 16 123 Class 150 170 PN 16 122 Table E 122

450 18 PN 6 101 PN 10 114 PN 16 140 Class 150 193 PN 16 135 Table E 145

500 20 PN 6 116 PN 10 134 PN 16 180 Class 150 230 PN 16 184 Table E 184

600 24 PN 6 157 PN 10 164 PN 16 225 Class 150 304 PN 16 262 Table E 262

Weight data of Promag W in kg (for standard pressure ratings and excluding packaging material)

Remote version (sensor and connection housing) excluding connecting cable, transmitter and batteries

DN EN (DIN) ASME, AWWA AS

[mm] [in]

Pres-

sure

rating

[kg]

Pres-

sure

rating

[kg]

Pres-

sure

rating

[kg]

Pressure

rating [kg]

Pres-

sure

rating

[kg]

Pres-

sure

rating

[kg]

350 14 PN 6 76 PN 10 87 PN 16 105 Class 150 136 PN 16 98 Table E 98

375 15 PN 6 – PN 10 – PN 16 – Class 150 – PN 16 104 Table E –

400 16 PN 6 88 PN 10 103 PN 16 123 Class 150 167 PN 16 119 Table E 119

450 18 PN 6 98 PN 10 111 PN 16 140 Class 150 190 PN 16 132 Table E 142

500 20 PN 6 113 PN 10 131 PN 16 180 Class 150 227 PN 16 181 Table E 181

600 24 PN 6 154 PN 10 161 PN 16 225 Class 150 301 PN 16 259 Table E 259](https://image.slidesharecdn.com/prolinepromagw800-endresshauserdatasheet-electromagneticflowmeter-210818172853/85/Proline-promag-w-800-endress-hauser-datasheet-electromagnetic-flowmeter-46-320.jpg)

![Proline Promag W 800

Endress+Hauser 47

Weight in US units

Promag W (standard)

Promag W (fully welded sensor option)

Weight data of Promag W in lbs (excluding packaging material)

Nominal

diameter

Compact version

(sensor and transmitter)

excluding batteries

Remote version

(sensor and connection housing)

excluding connecting cable, transmitter and

batteries

[mm] [in] ASME ASME

25 1"

Class

150

11.7

Class

150

11.7

32 – – –

40 1 ½" 16.3 16.3

50 2" 19.0 19.0

65 – – –

80 3" 26.5 26.5

100 4" 30.9 30.9

125 – – –

150 6" 51.8 51.8

200 8" 94.8 94.8

250 10" 139 161

300 12" 238 238

350 14" 382 382

400 16" 448 448

450 18" 558 558

500 20" 624 624

600 24" 889 889

Transmitter remote version = 3.3 lbs

Weight of battery block with: one battery = 3.53 oz/two batteries = 6.7 oz/three batteries = 10.2 oz

Weight data of Promag W in lbs (for standard pressure ratings and excluding packaging material)

Nominal

diameter

Remote version (sensor and connection housing)

excluding connecting cable, transmitter and batteries

[mm] [in] ASME

50 2"

Class

150

19.9

65 – –

80 3" 28.7

100 4" 37.5

125 – –

150 6" 57.3

200 8" 92.6

250 10" 130

300 12" 185

Transmitter remote version = 3.3 lbs

Weight of battery block with: one battery = 3.53 oz/two batteries = 6.7 oz/three batteries = 10.2 oz](https://image.slidesharecdn.com/prolinepromagw800-endresshauserdatasheet-electromagneticflowmeter-210818172853/85/Proline-promag-w-800-endress-hauser-datasheet-electromagnetic-flowmeter-47-320.jpg)

![Proline Promag W 800

48 Endress+Hauser

Order code for "Design", option A "Insertion length short" with DN 14 to 24"

Order code for "Design", option A "Insertion length short" with DN 14 to 24"

Measuring tube specifications

Weight data of Promag W in lbs (for standard pressure ratings and excluding packaging material)

Compact version (sensor and transmitter) excluding batteries

DN ASME, AWWA

[mm] [in] Pressure rating [lbs]

350 14 Class 150 306

375 15 Class 150 –

400 16 Class 150 375

450 18 Class 150 425

500 20 Class 150 507

600 24 Class 150 670

Weight data of Promag W in kg (for standard pressure ratings and excluding packaging material)

Remote version (sensor and connection housing) excluding connecting cable, transmitter and batteries

DN ASME, AWWA

[mm] [in] Pressure rating [lbs]

350 14 Class 150 301

375 15 Class 150 –

400 16 Class 150 369

450 18 Class 150 420

500 20 Class 150 501

600 24 Class 150 664

Nominal

diameter

Pressure rating Measuring tube internal diameter

EN (DIN) AS 2129 AS 4087 ASME JIS Hard rubber Polyurethane

[mm] [in] [mm] [in] [mm] [in]

25 1" PN 40 – – Class 150 20K – – 24 0.94

32 – PN 40 – – – 20K – – 32 1.26

40 1 ½" PN 40 – – Class 150 20K – – 38 1.50

50 2" PN 40 Table E PN16 Class 150 10K 50 1.97 50 1.97

65 – PN 16 – – – 10K 66 2.60 66 2.60

80 3" PN 16 Table E PN16 Class 150 10K 79 3.11 79 3.11

100 4" PN 16 Table E PN16 Class 150 10K 102 4.02 102 4.02

125 – PN 16 – – – 10K 127 5.00 127 5.00

150 6" PN 10 Table E PN16 Class 150 10K 156 6.14 156 6.14

200 8" PN 10 Table E PN16 Class 150 10K 204 8.03 204 8.03

250 10" PN 10 Table E PN16 Class 150 10K 258 10.2 258 10.2

300 12" PN 10 Table E PN16 Class 150 10K 309 12.2 309 12.2

350 14" PN 6 Table E PN16 Class 150 – 342 13.5 342 13.5

375 15" – – PN16 – – 392 15.4 392 15.4

400 16" PN 6 Table E PN16 Class 150 – 392 15.4 392 15.4

450 18" PN 6 – – Class 150 – 437 17.2 437 17.2

500 20" PN 6 Table E PN16 Class 150 – 492 19.4 492 19.4

600 24" PN 6 Table E PN16 Class 150 – 594 23.4 594 23.4](https://image.slidesharecdn.com/prolinepromagw800-endresshauserdatasheet-electromagneticflowmeter-210818172853/85/Proline-promag-w-800-endress-hauser-datasheet-electromagnetic-flowmeter-48-320.jpg)