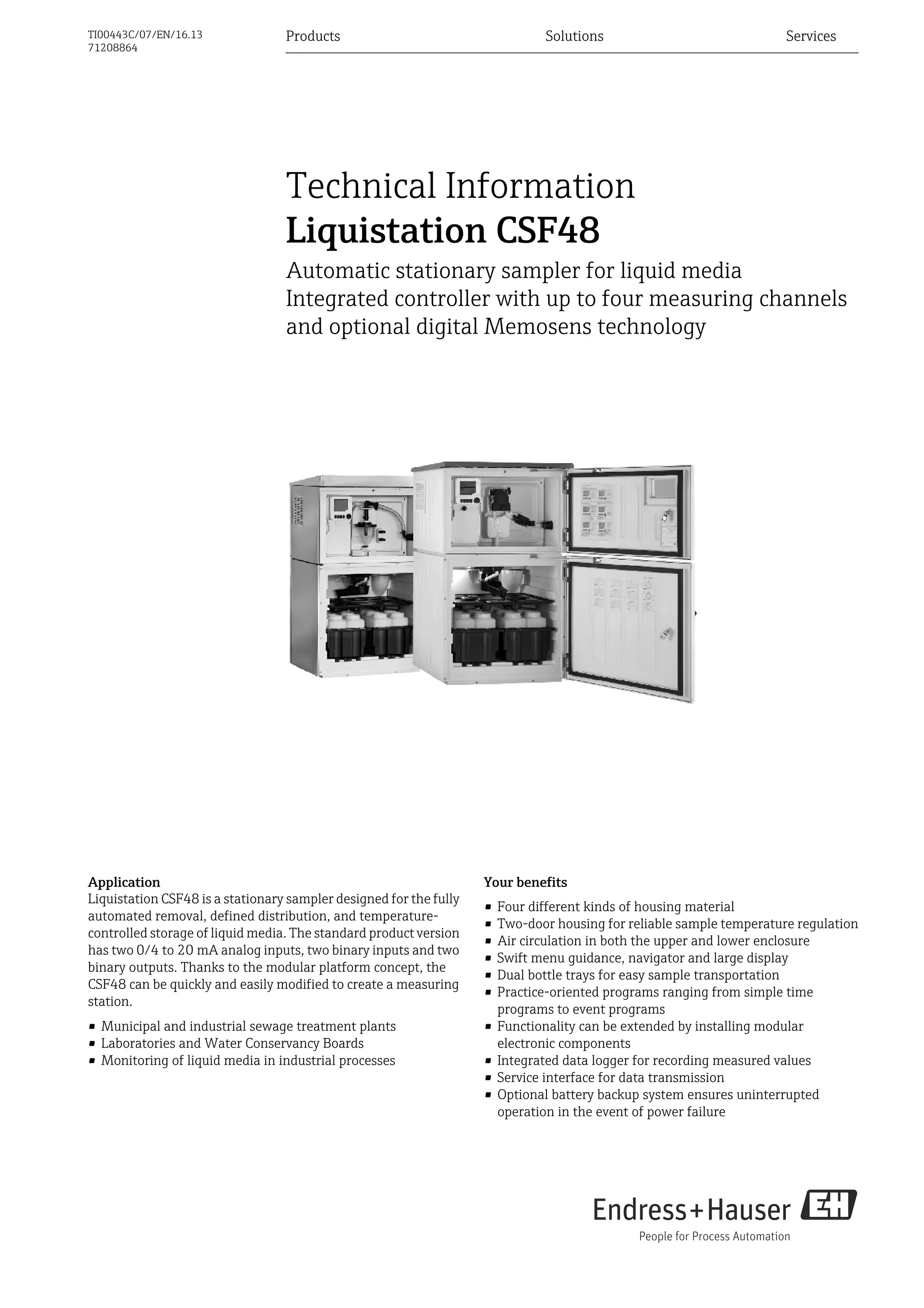

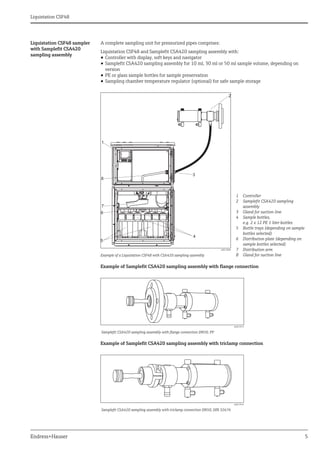

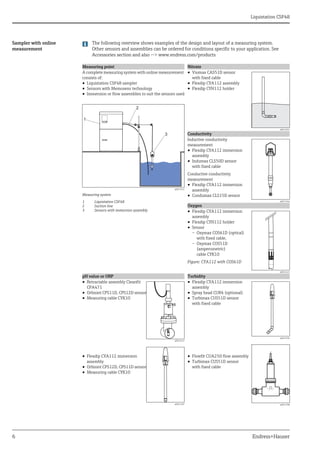

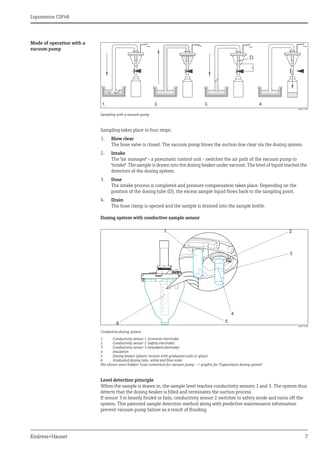

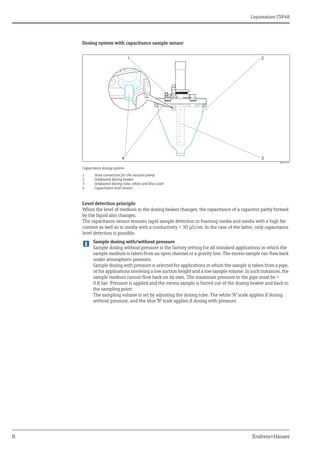

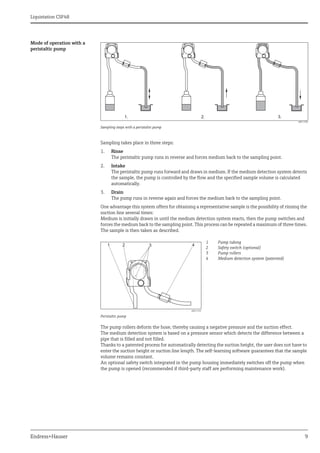

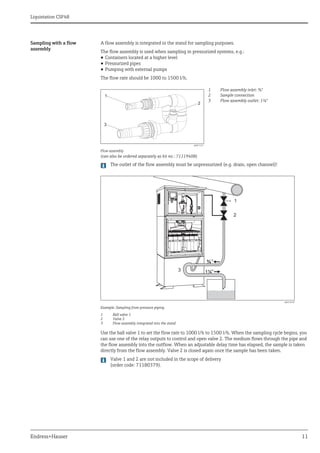

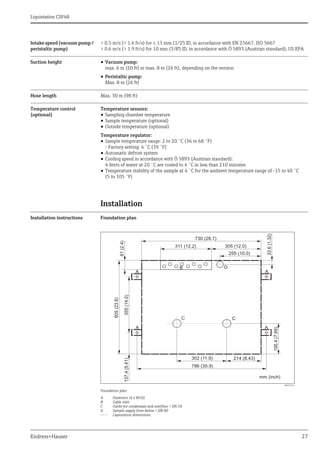

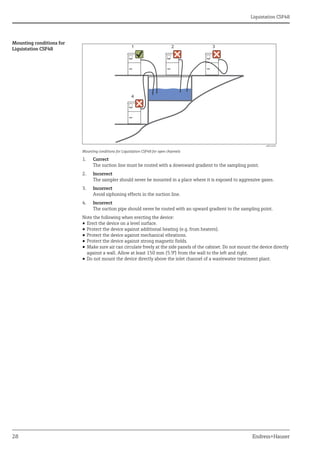

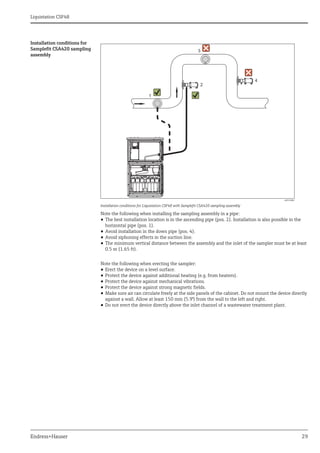

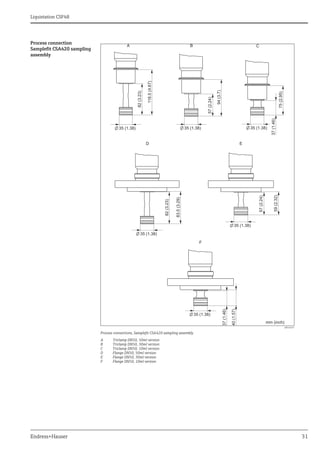

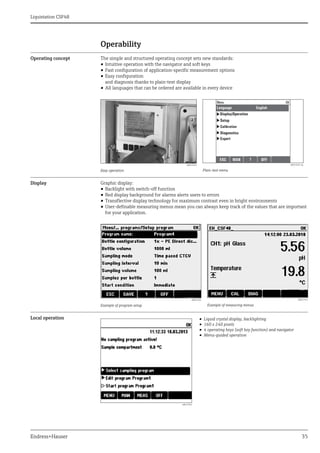

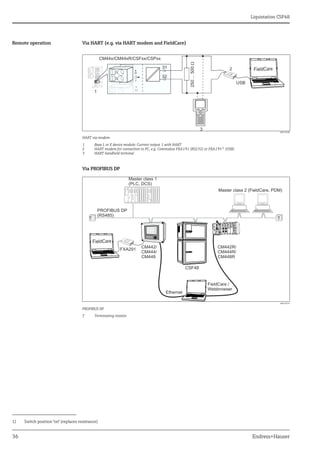

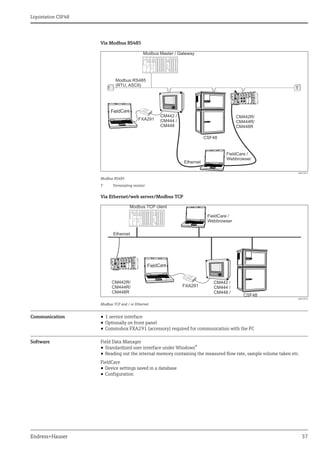

The document provides technical information about the Liquistation CSF48, an automatic stationary sampler designed for liquid media with an integrated controller. It outlines its applications in sewage treatment, laboratories, and industrial monitoring, and highlights features such as modular modification, various housing materials, temperature regulation, and data logging capabilities. The document details the operational modes, installation requirements, and environmental specifications necessary for effective use.