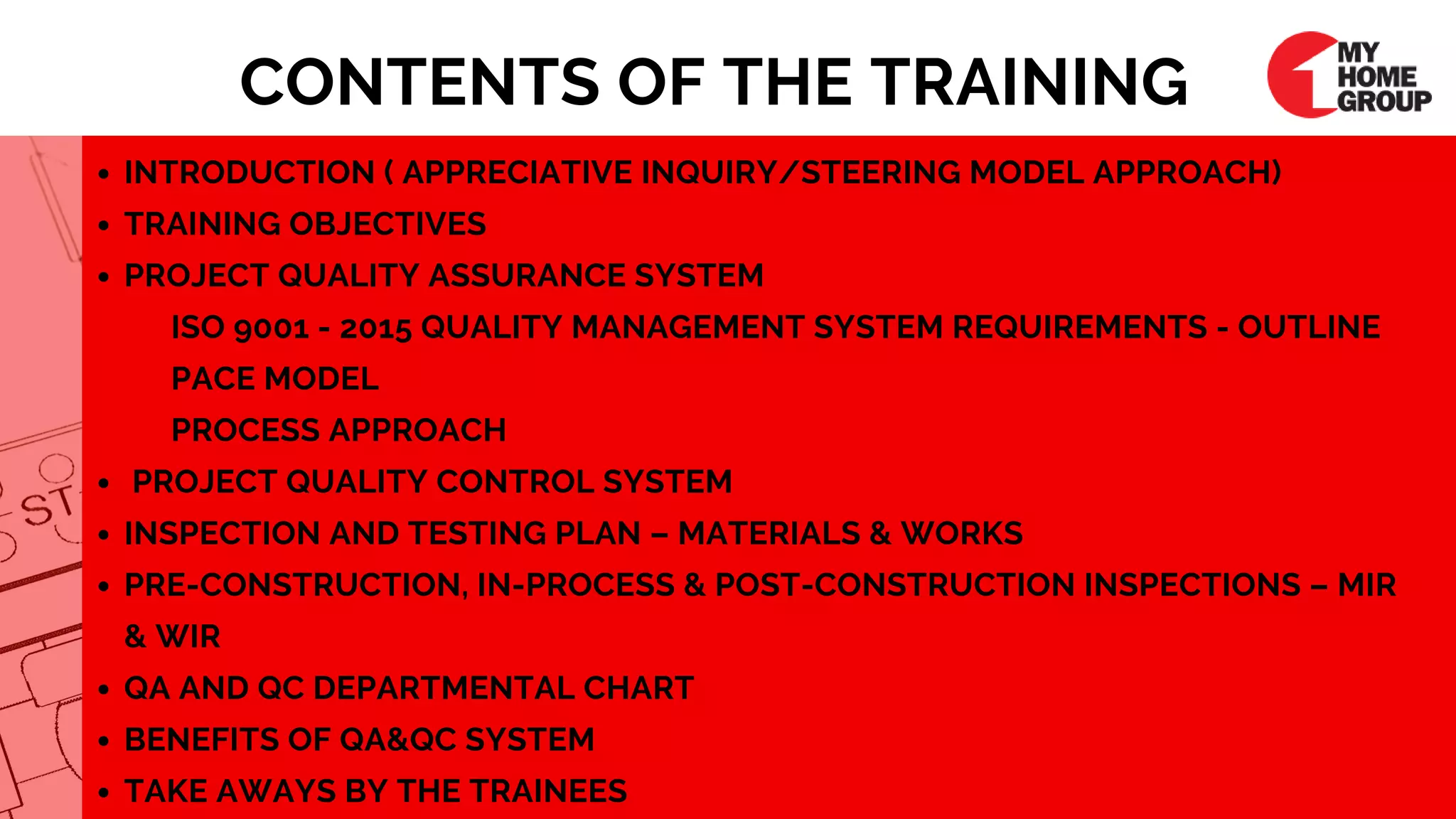

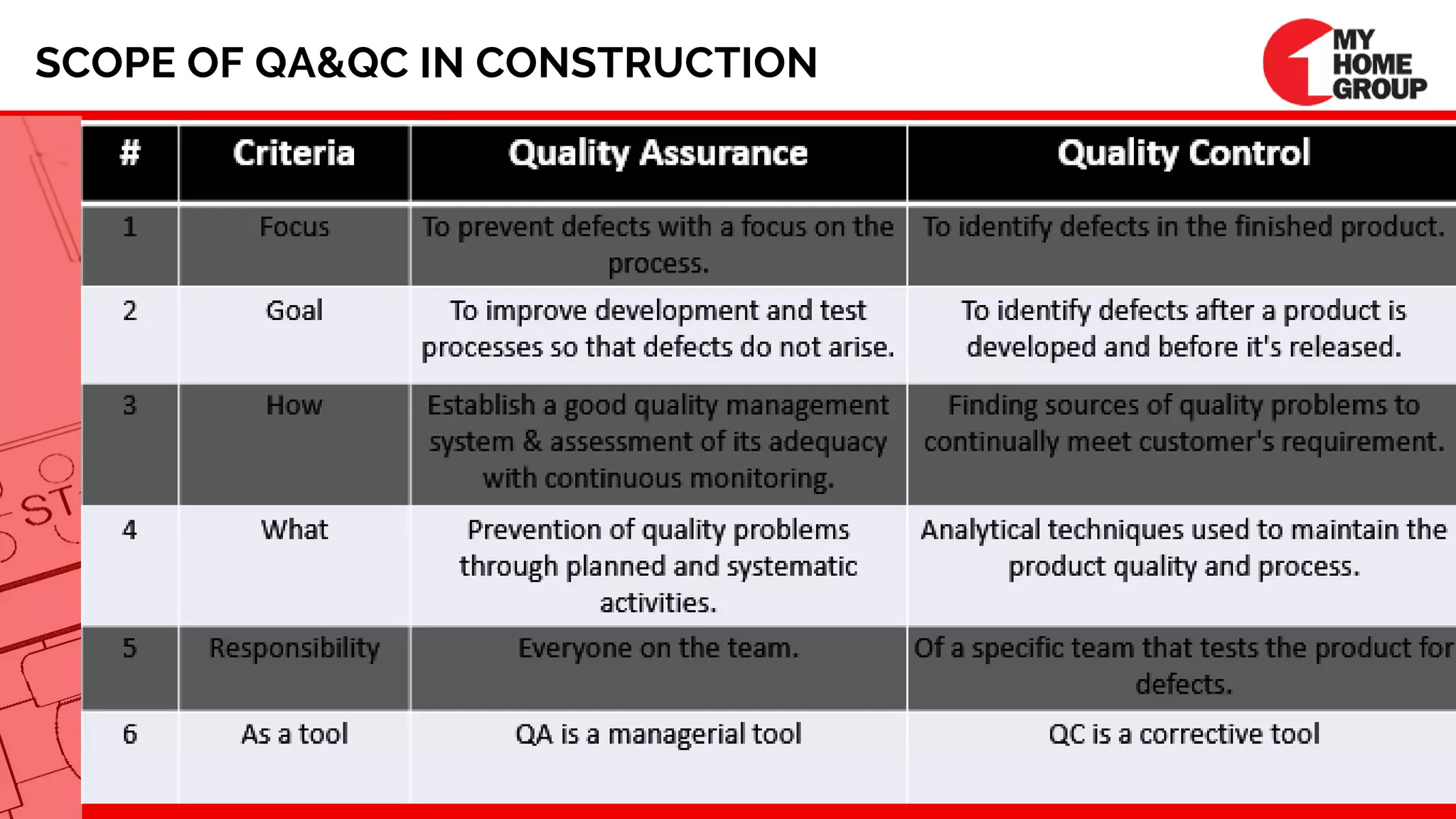

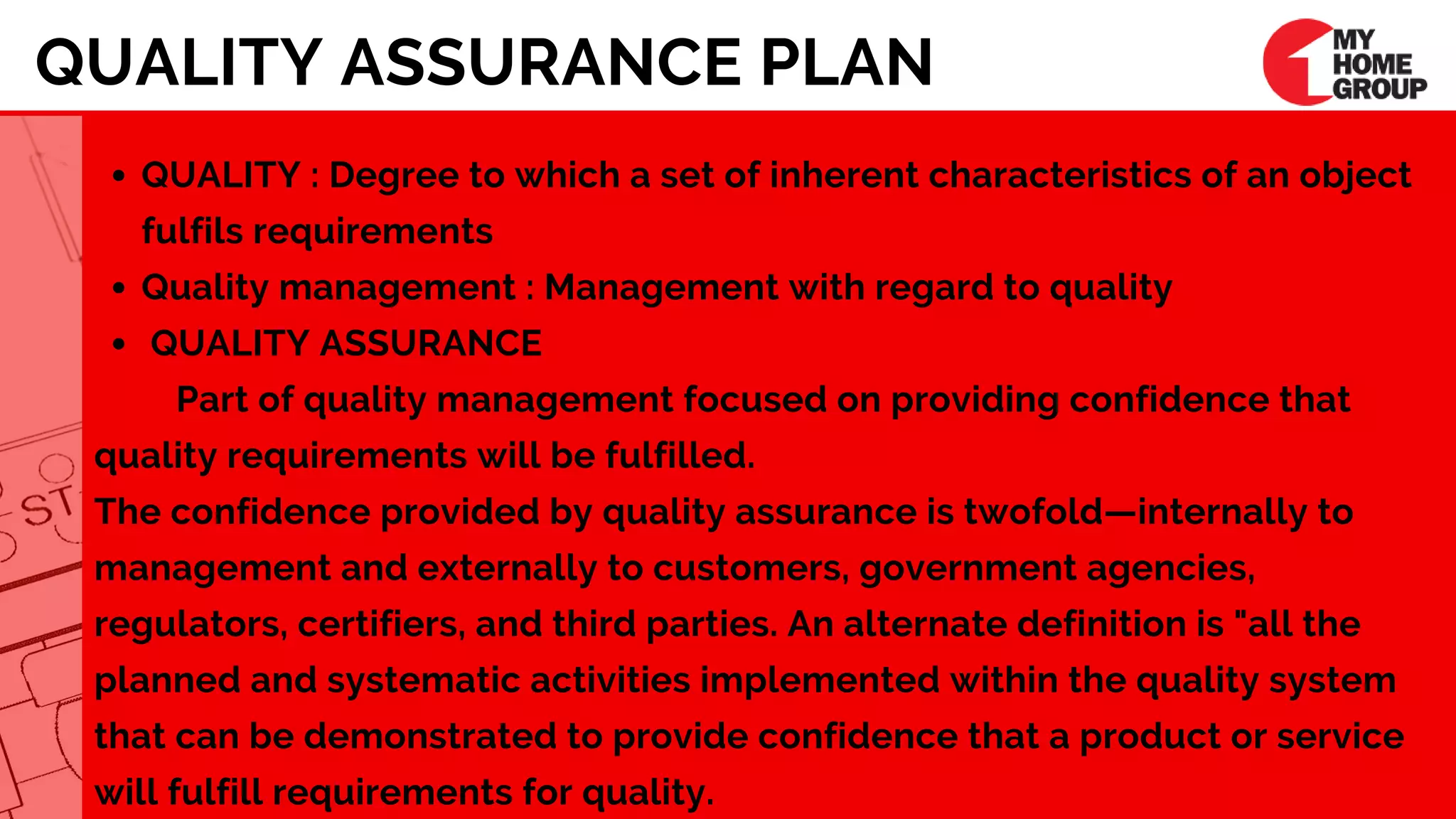

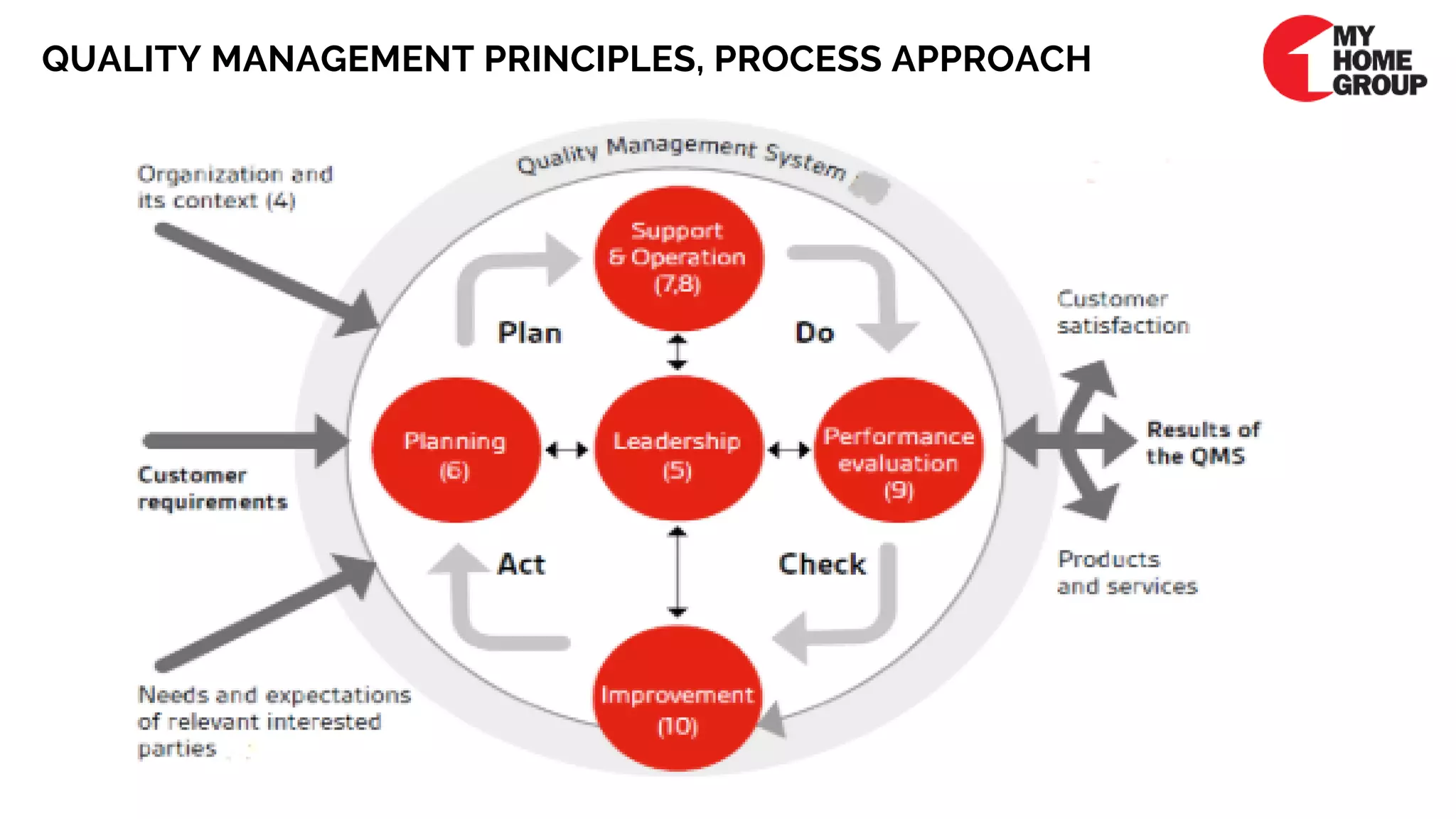

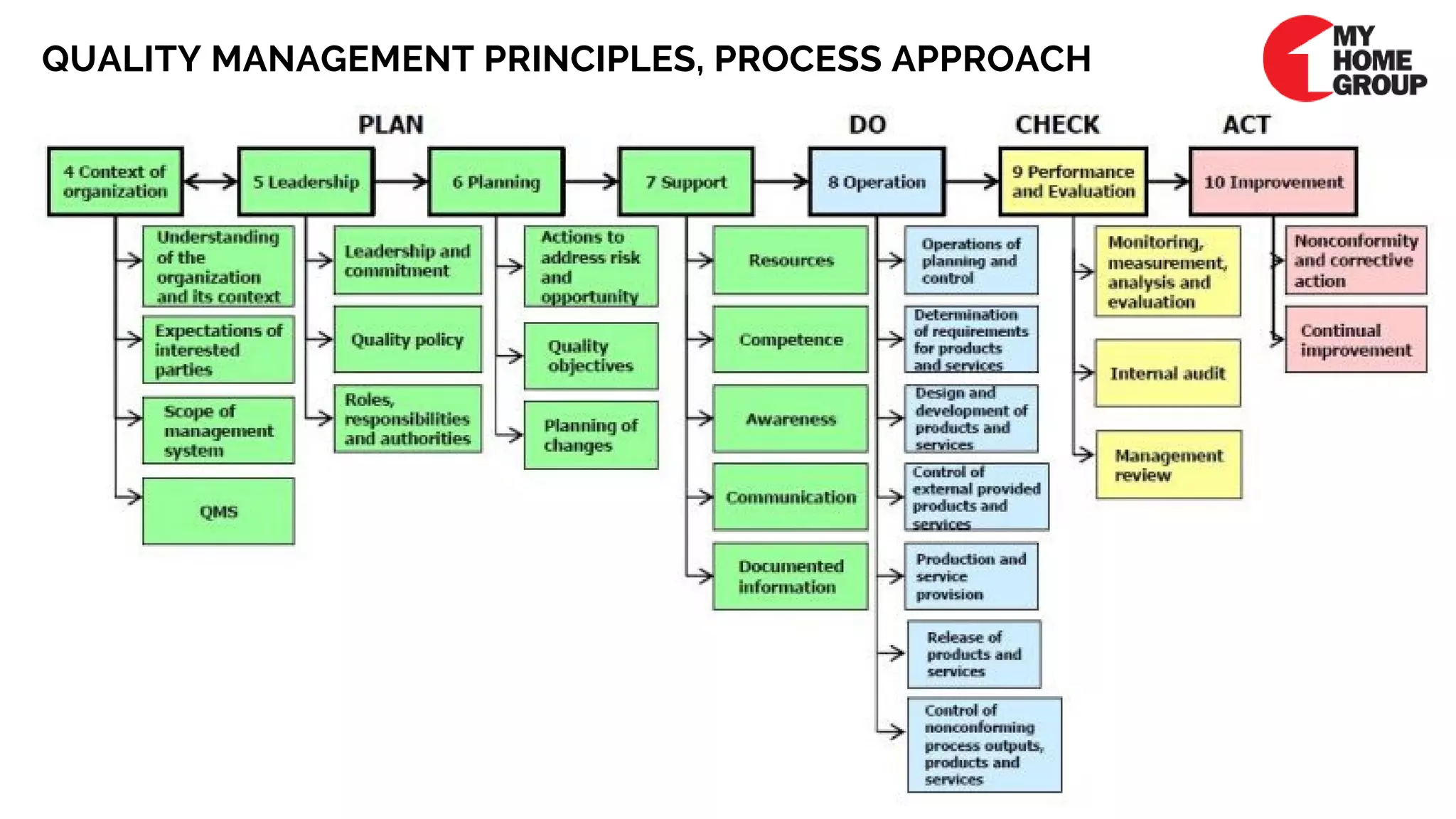

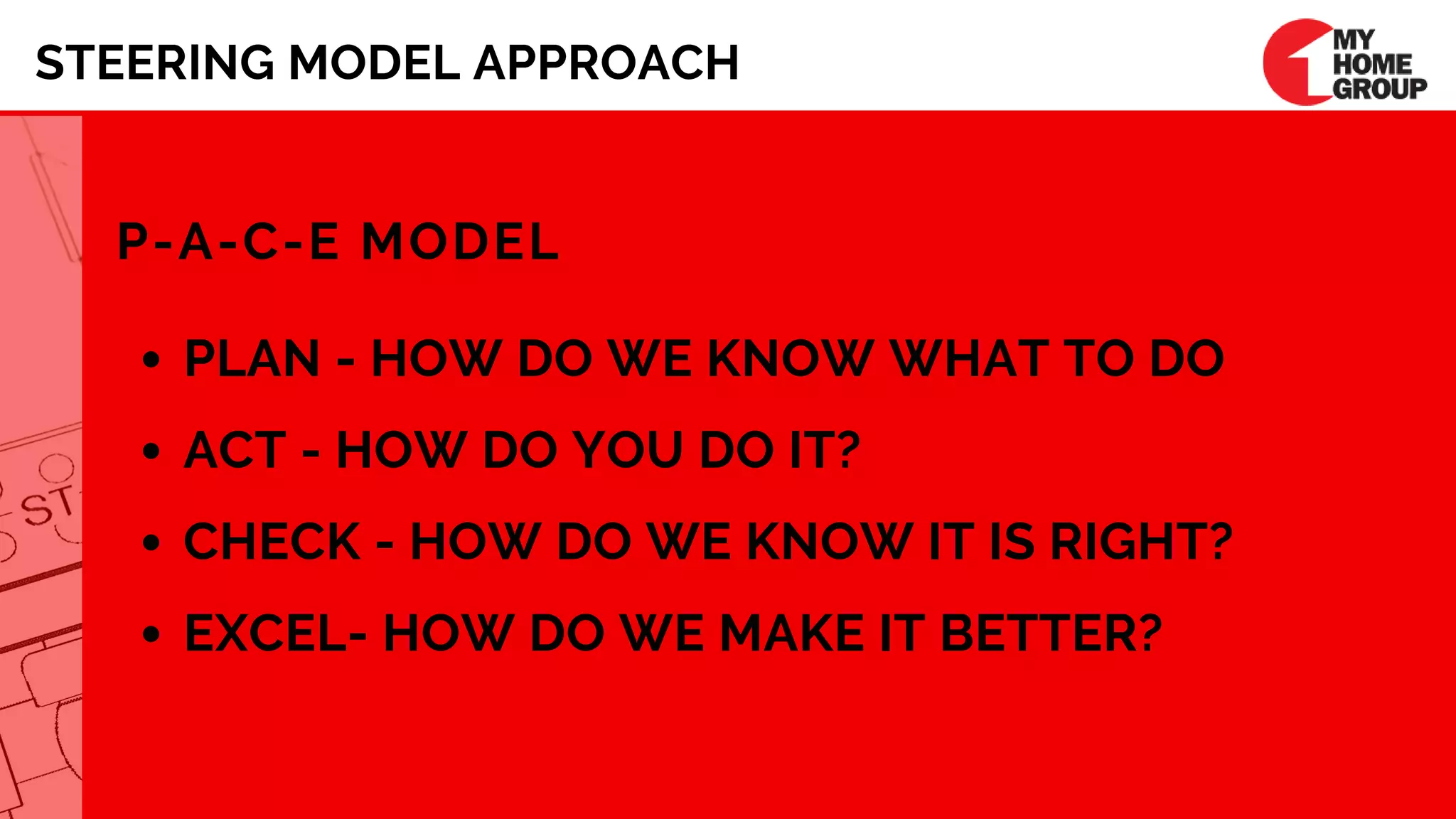

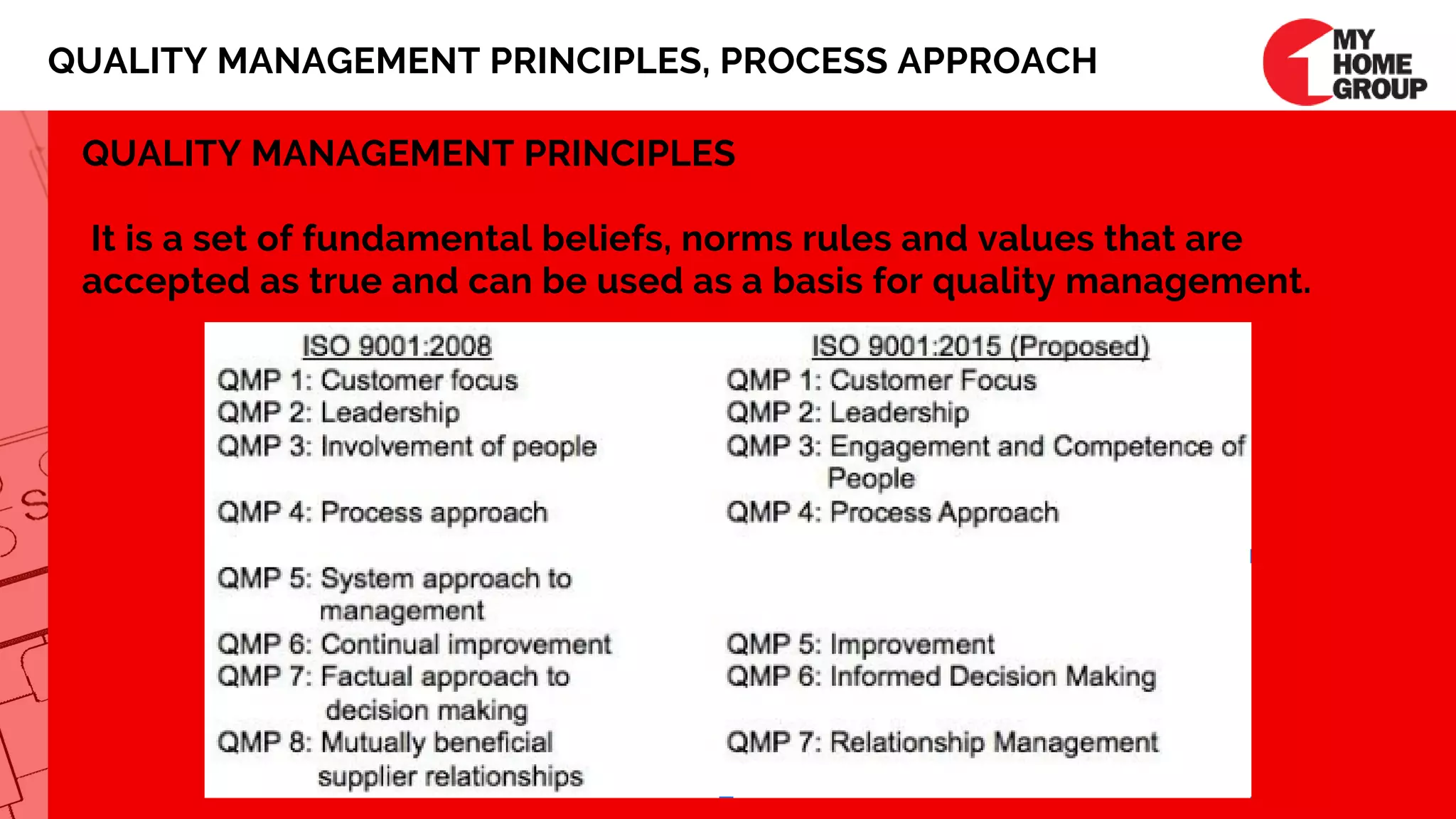

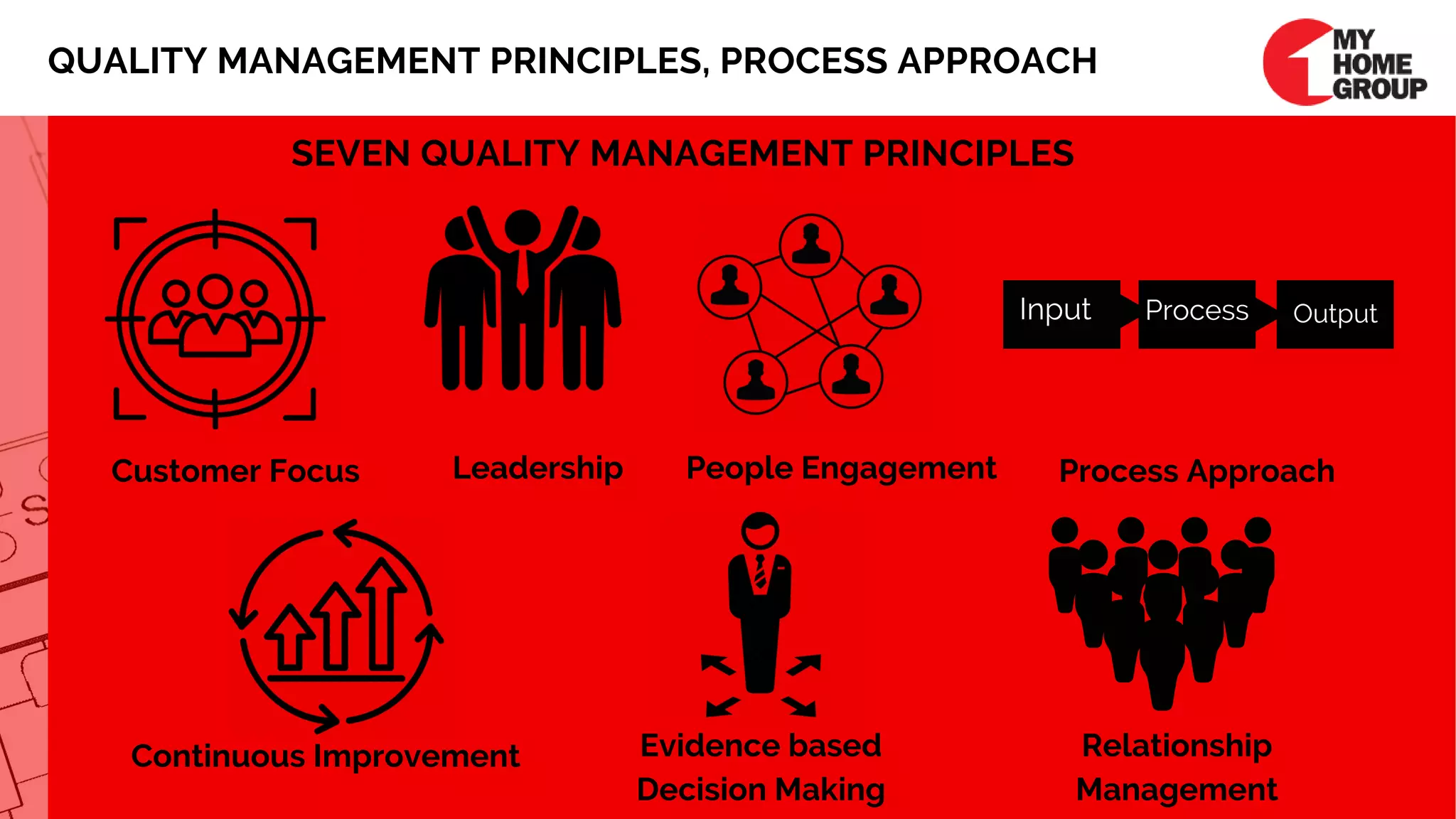

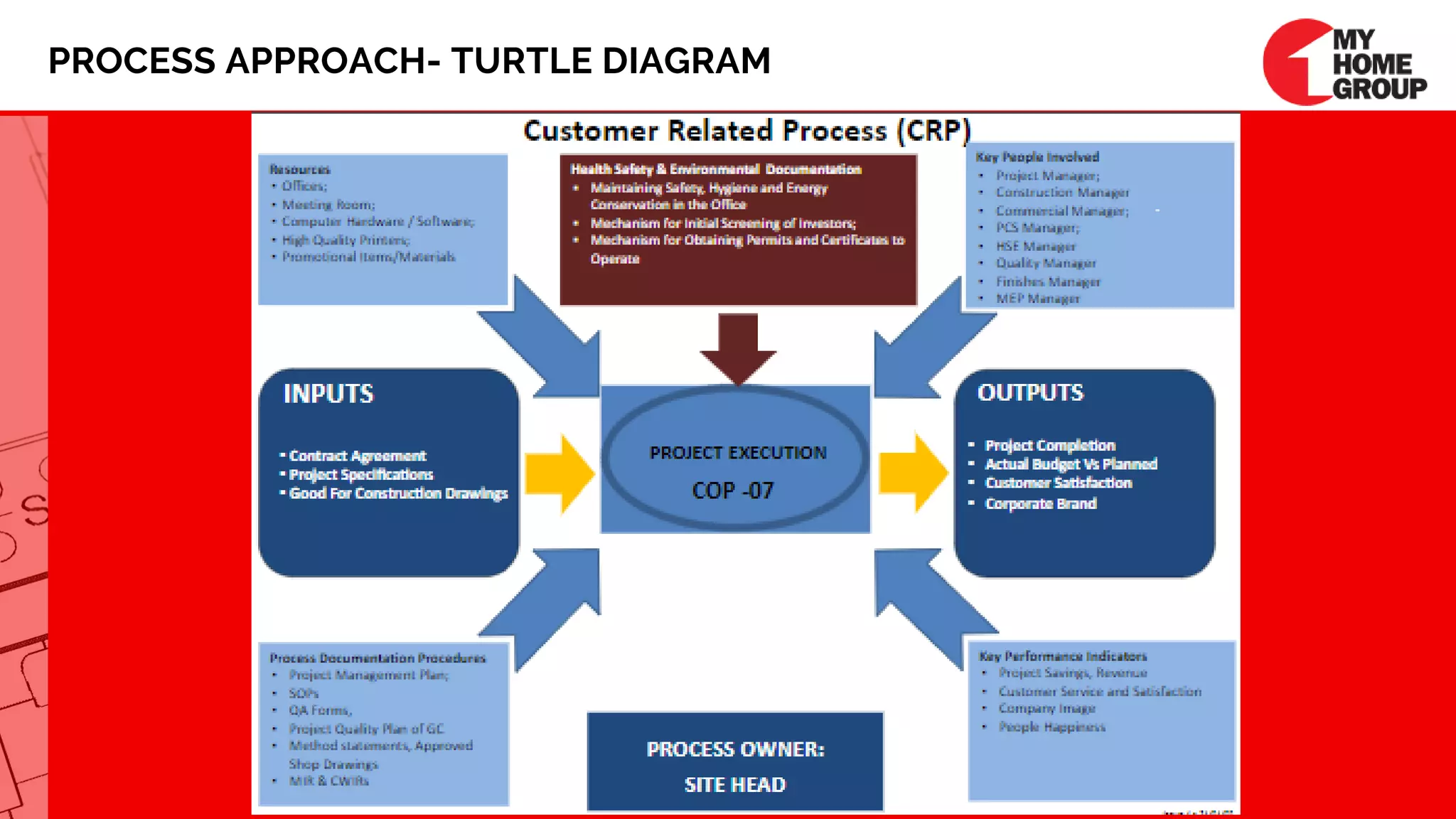

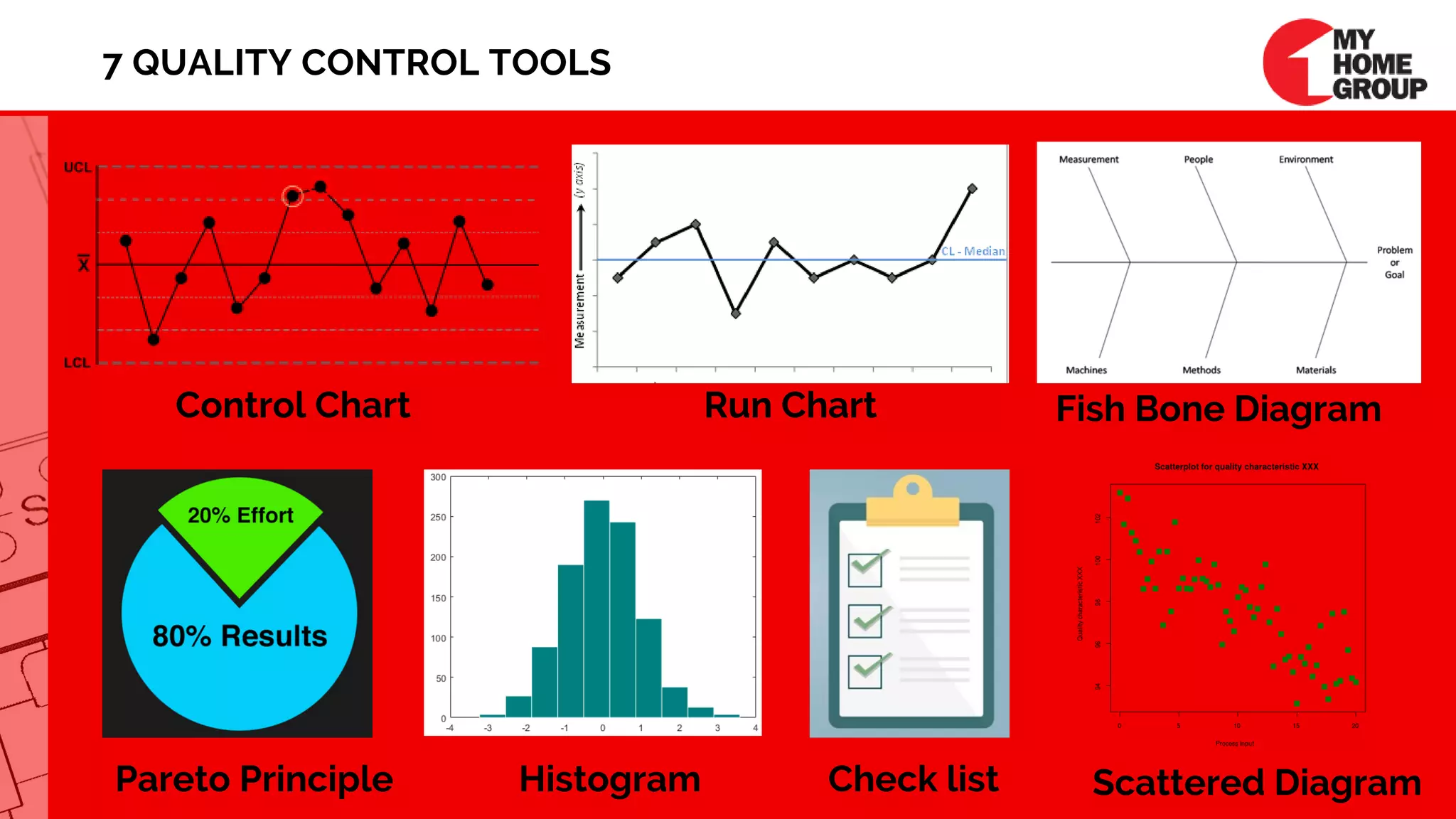

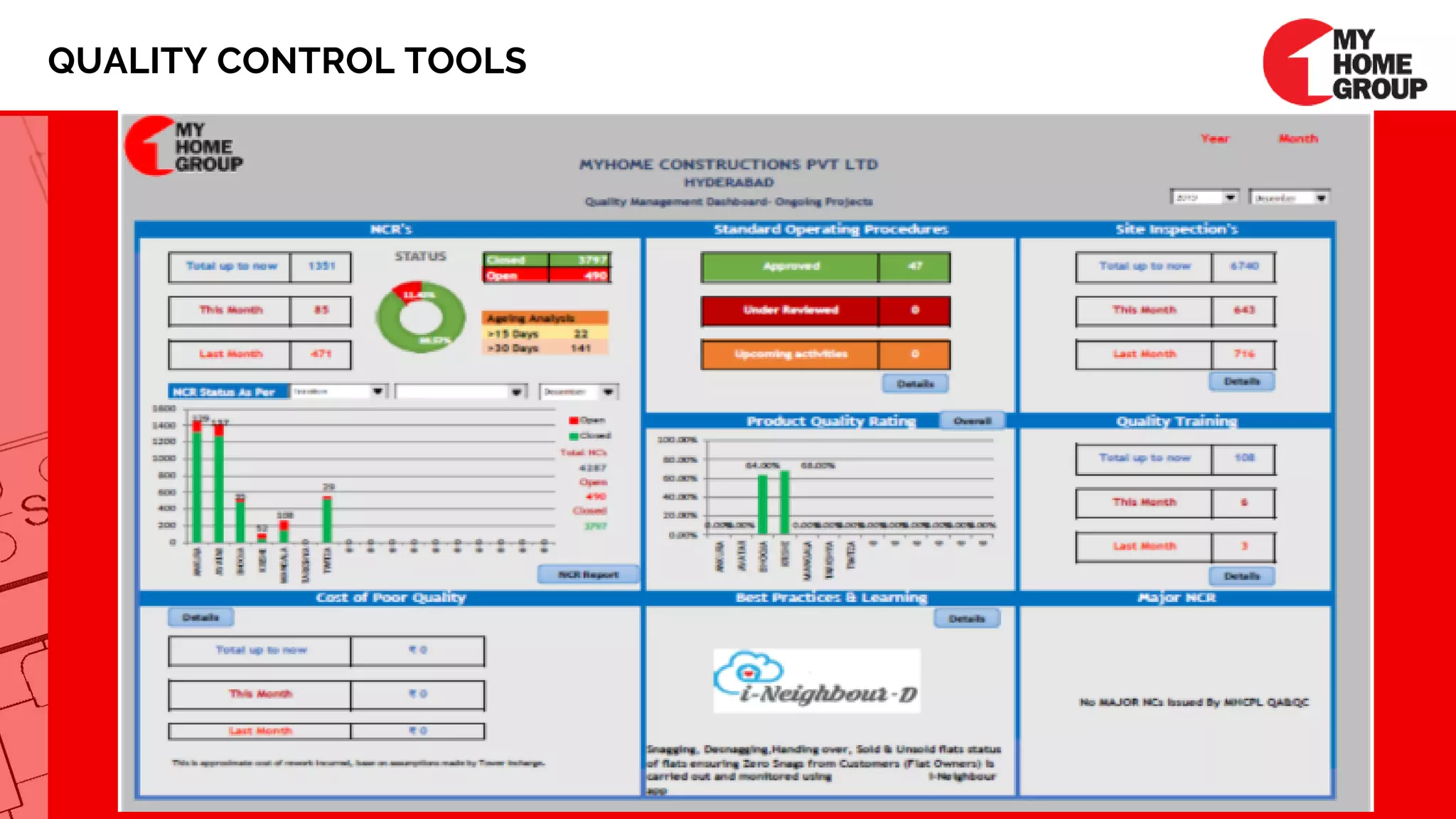

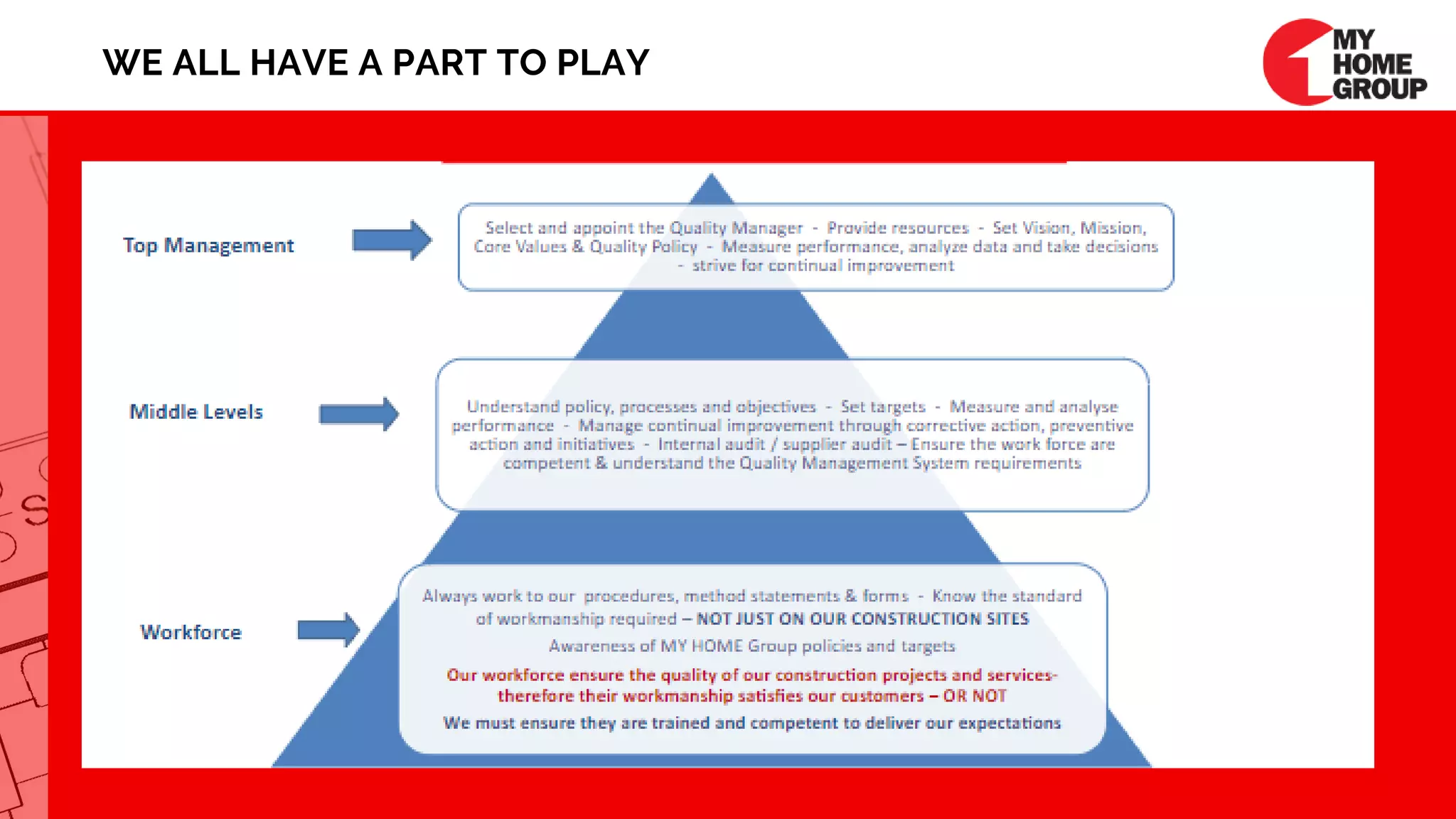

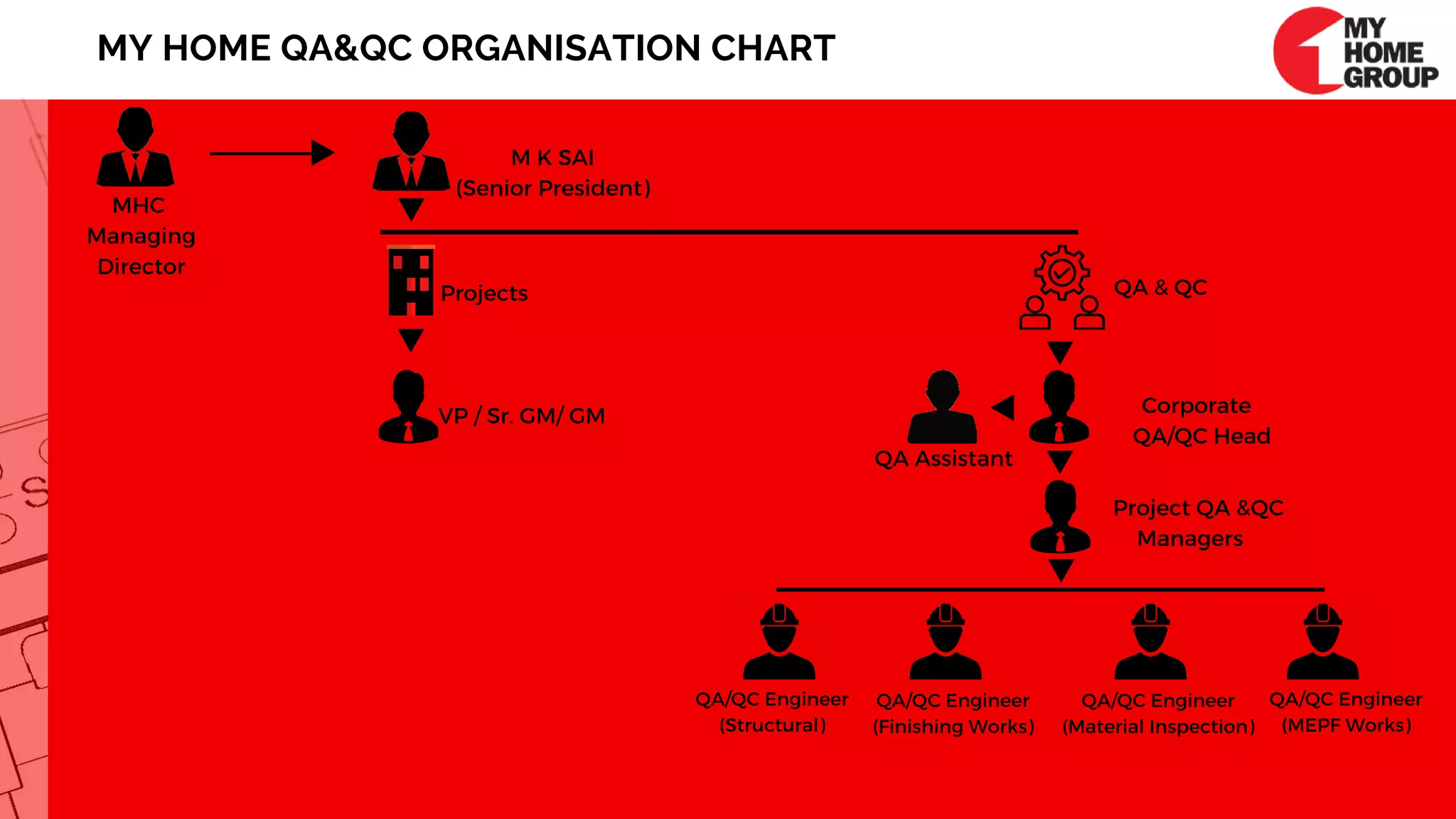

The document outlines a project quality assurance and control system led by corporate QA&QC head Nagareddayya Subbagari, focusing on training objectives related to ISO 9001:2015. It emphasizes the implementation of quality management principles and tools to achieve zero defects and improve overall quality consciousness among employees in construction processes. Key components include inspection plans, corrective actions, and continual improvement practices aimed at enhancing customer satisfaction and operational efficiency.