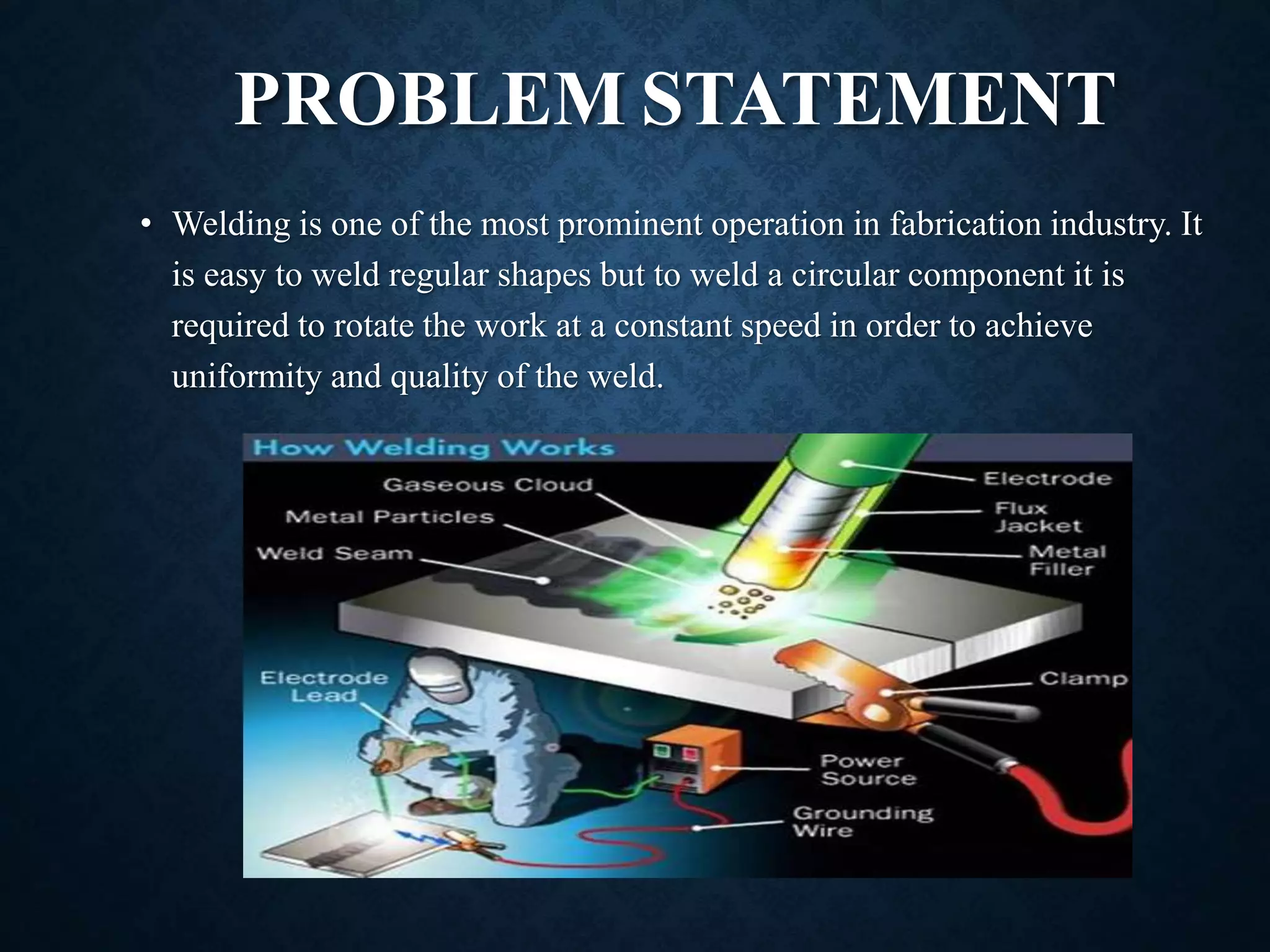

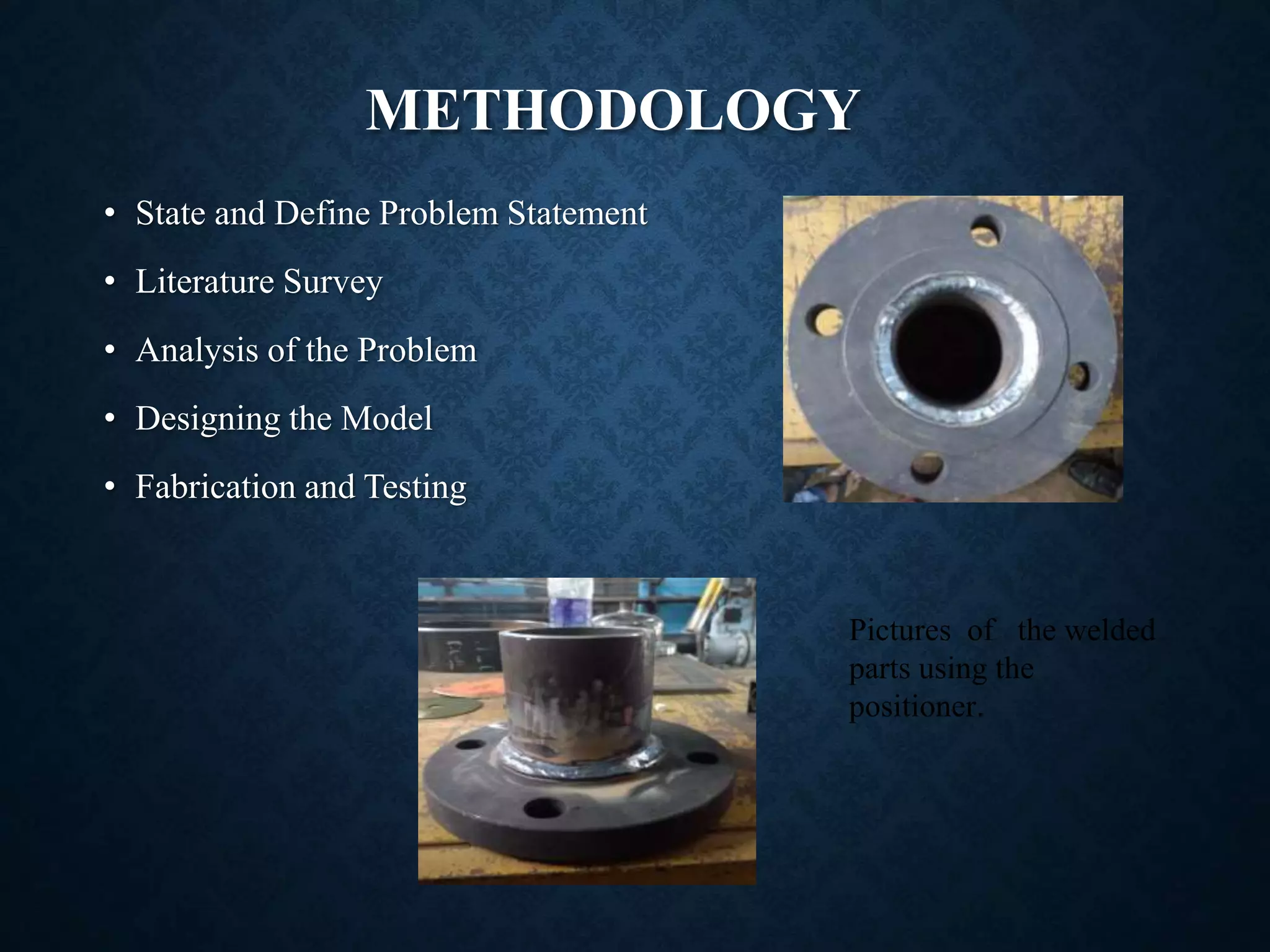

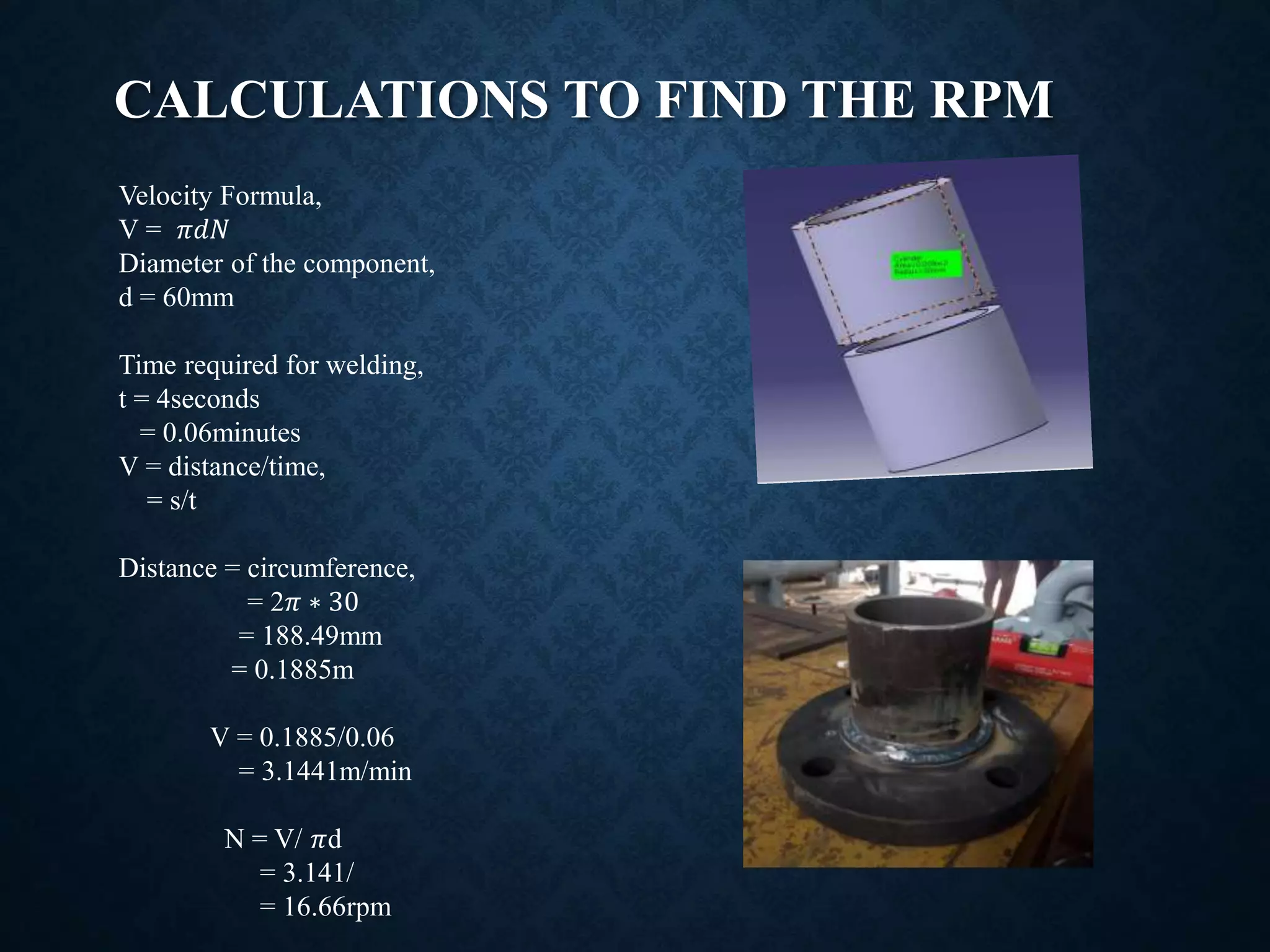

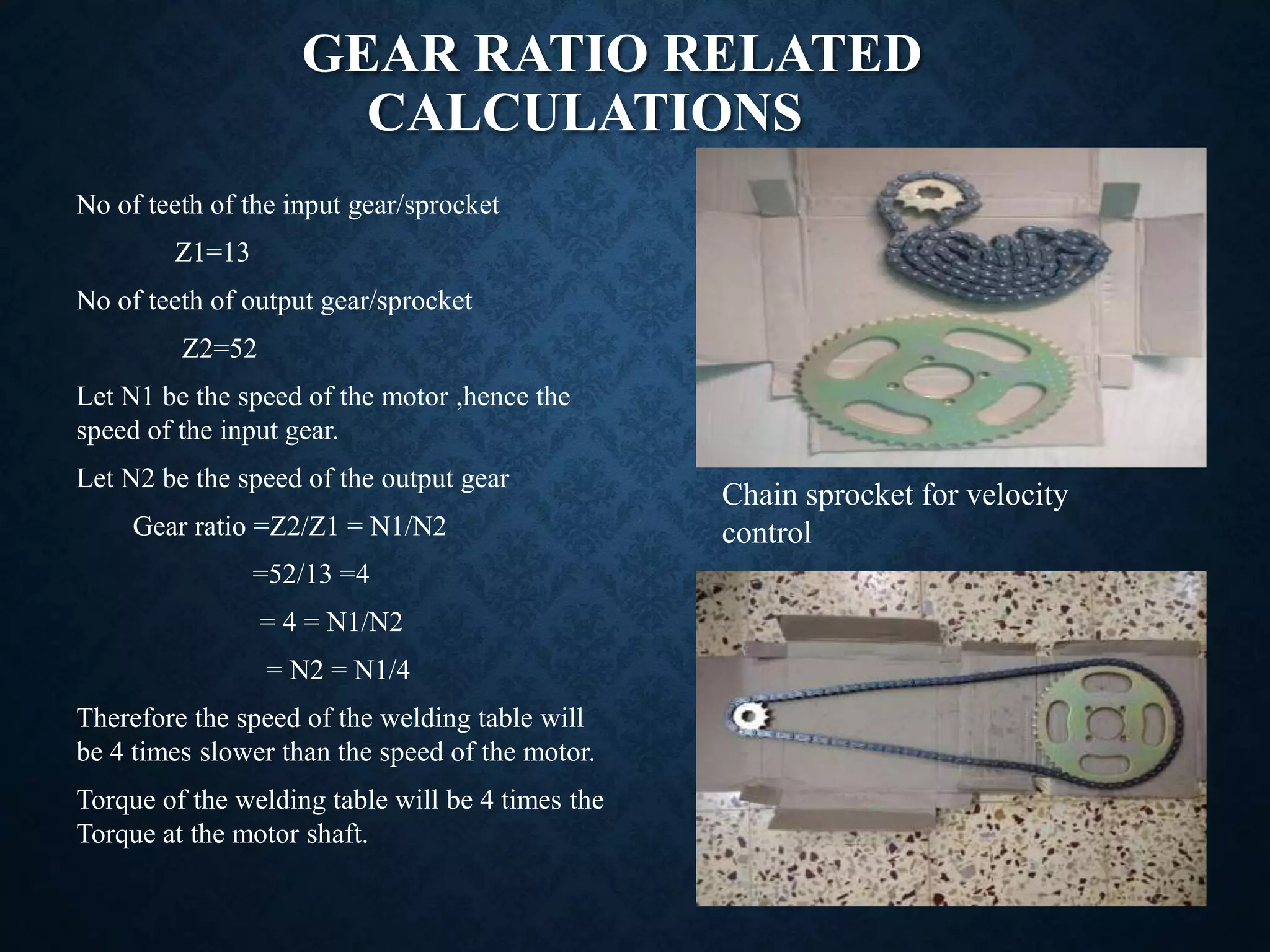

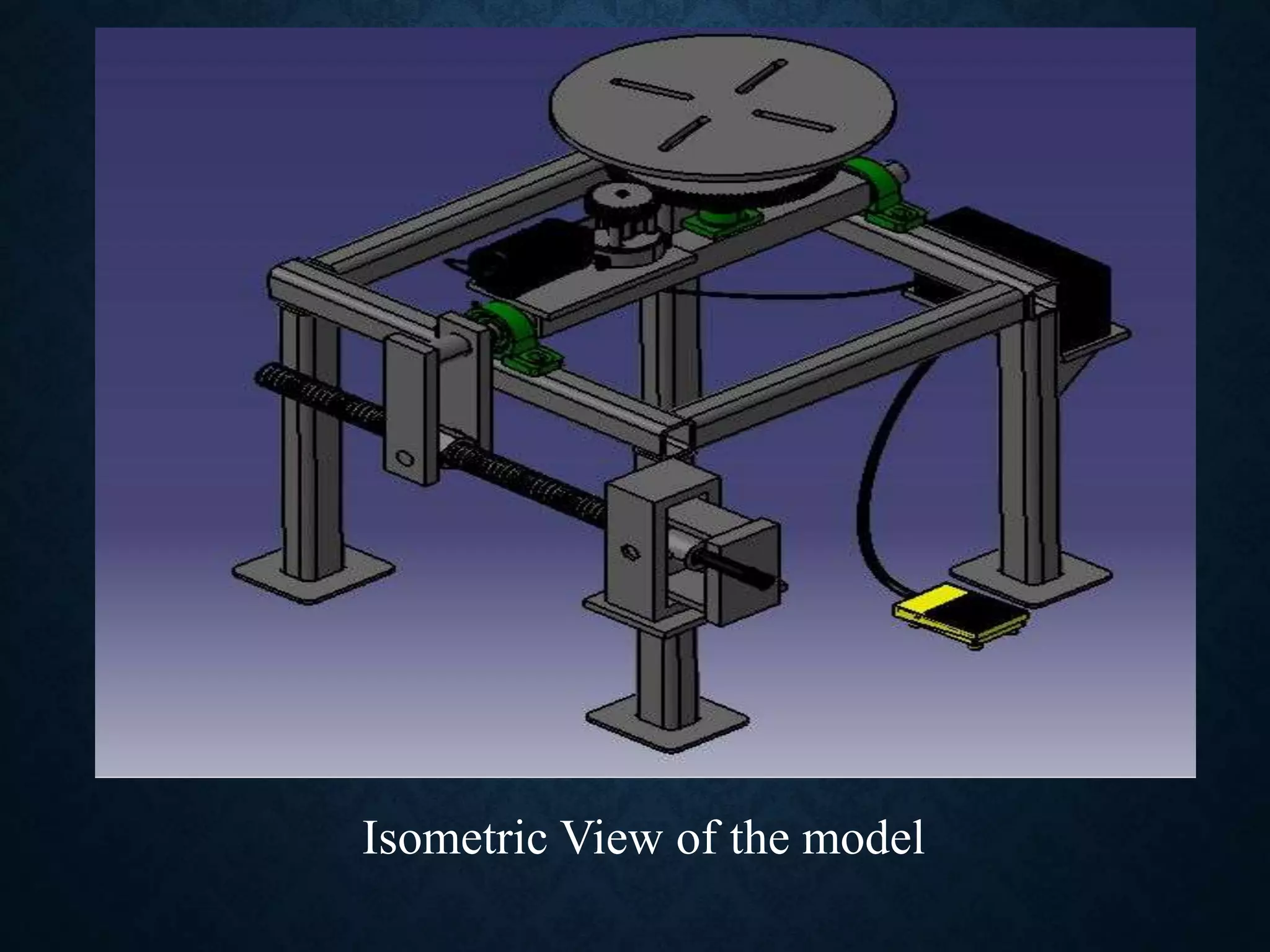

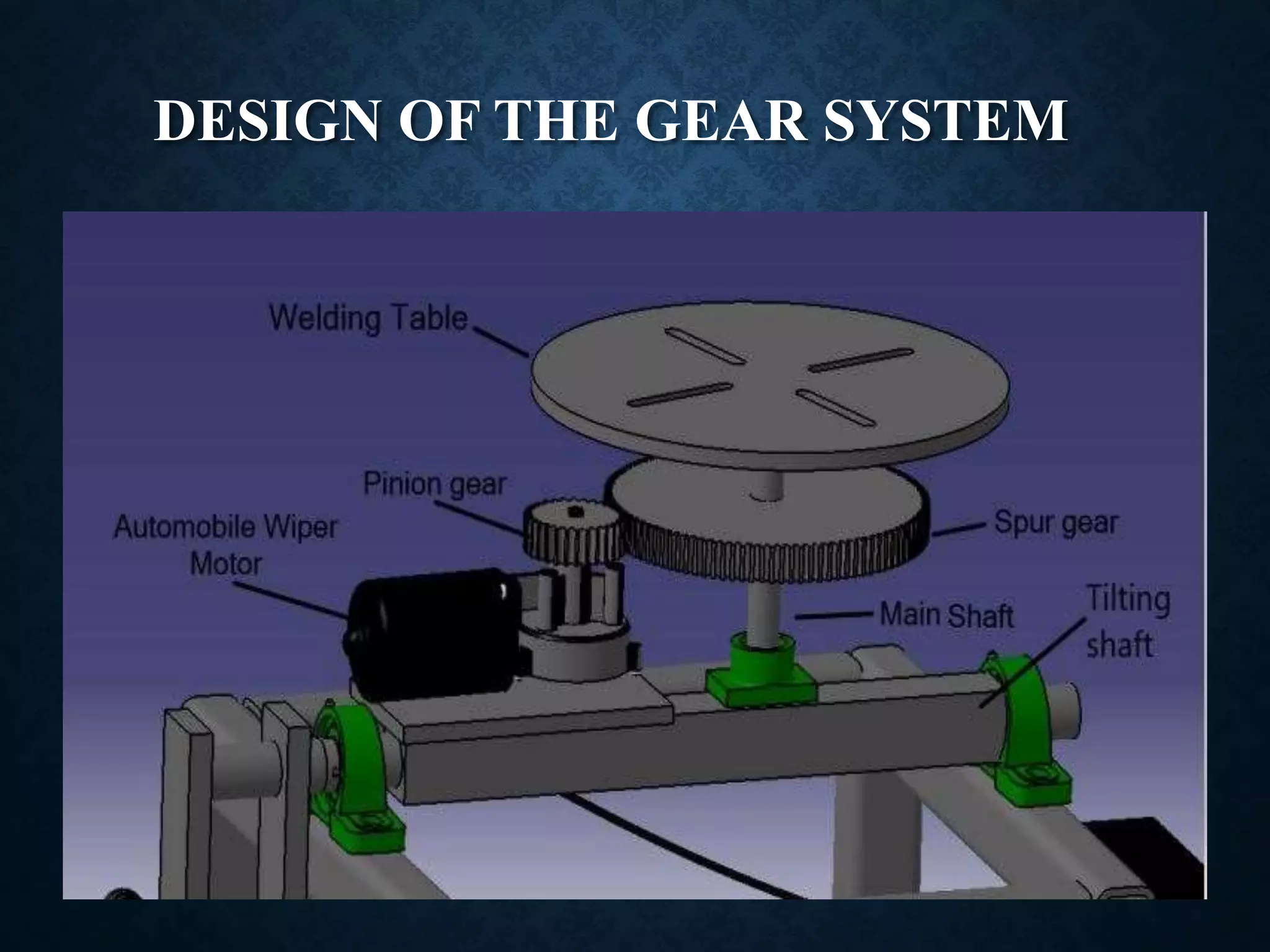

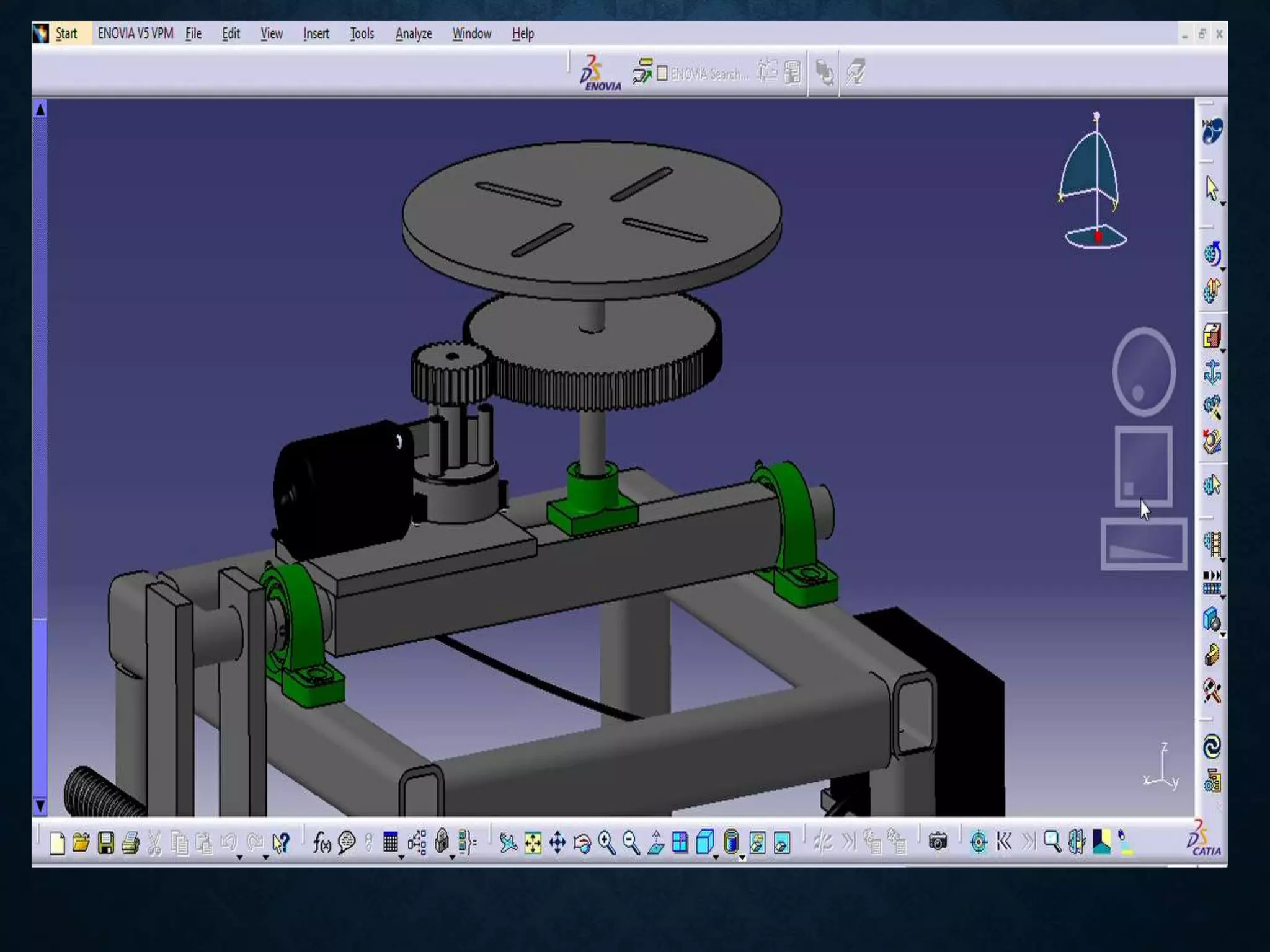

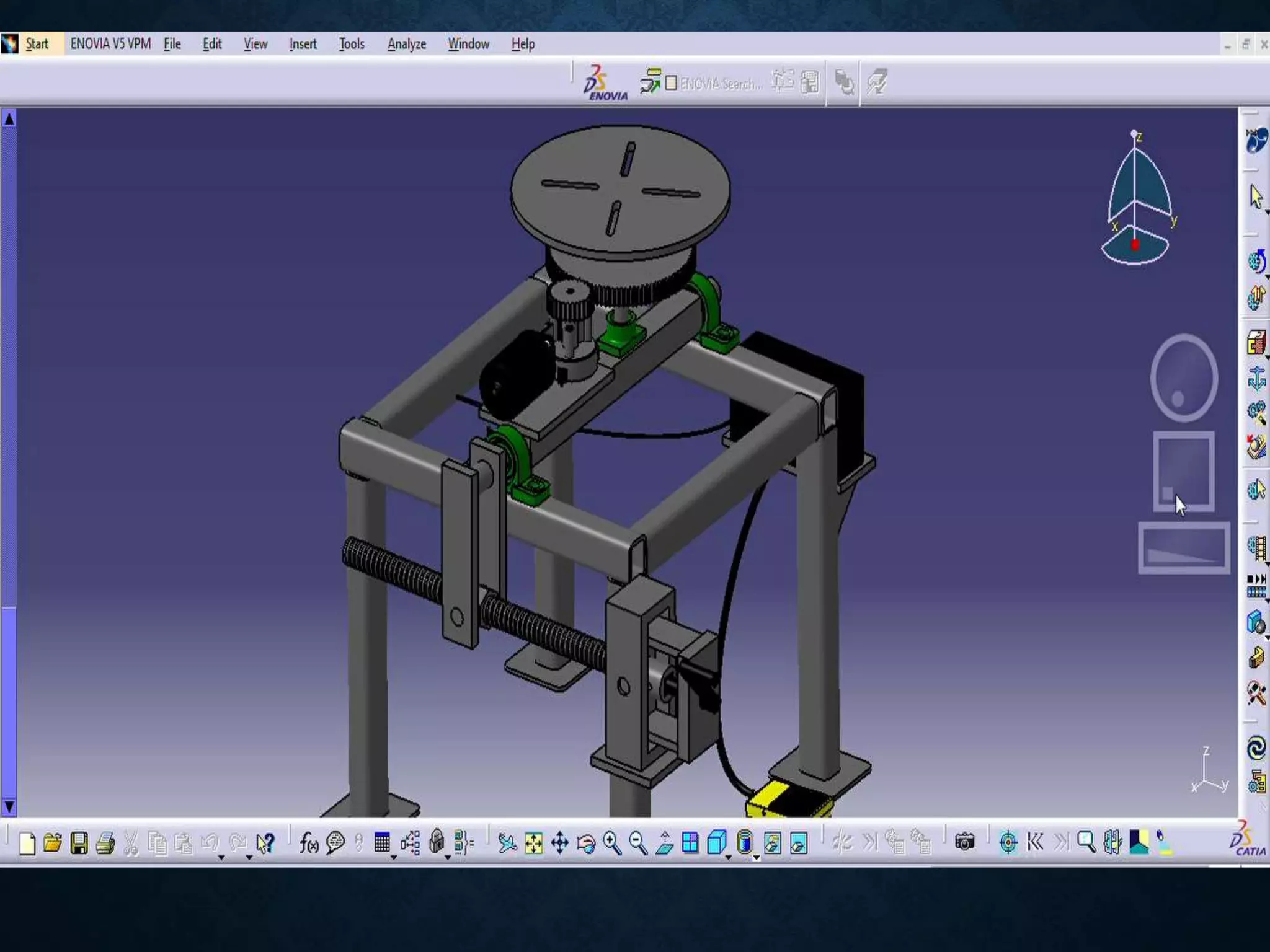

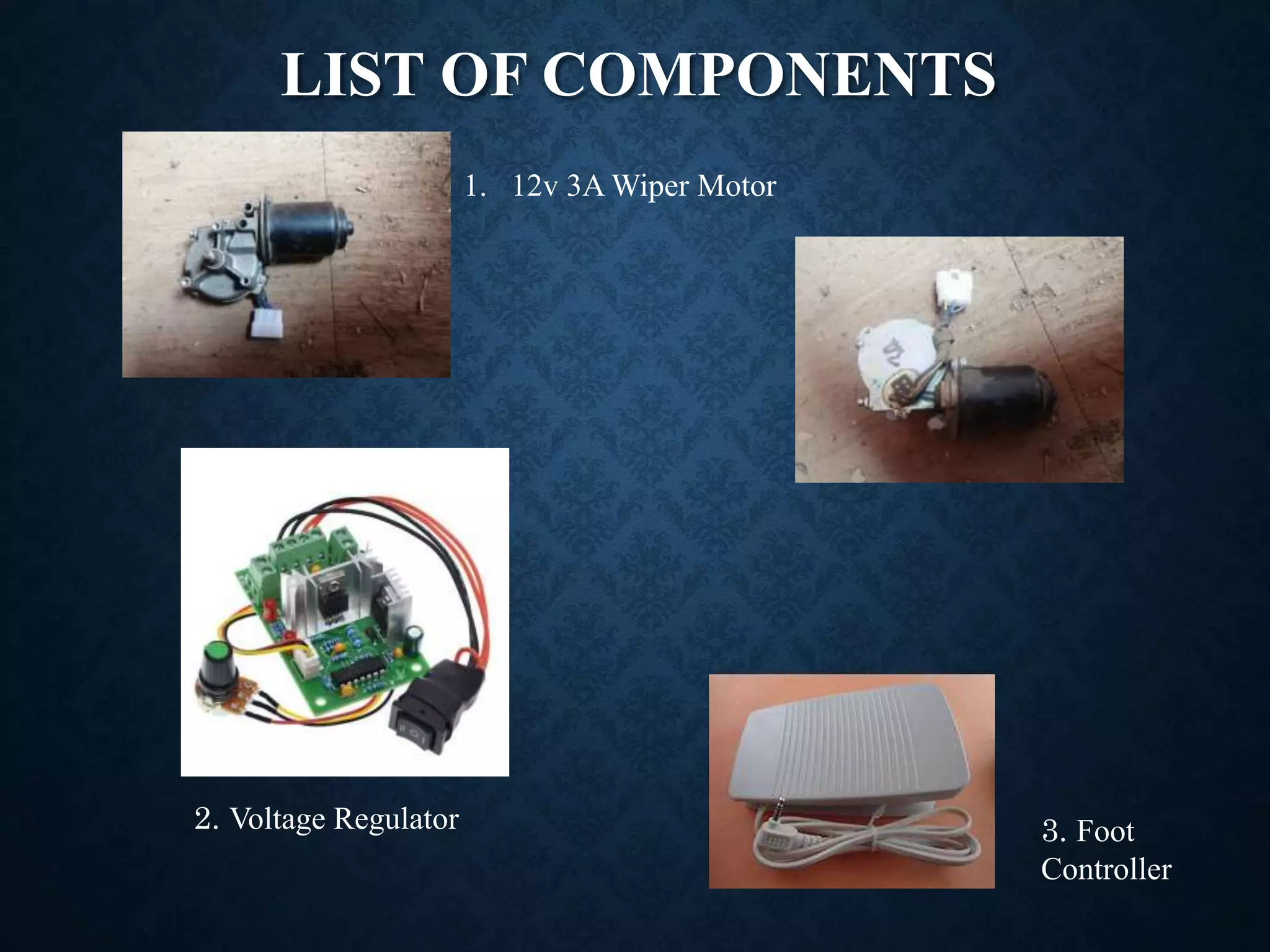

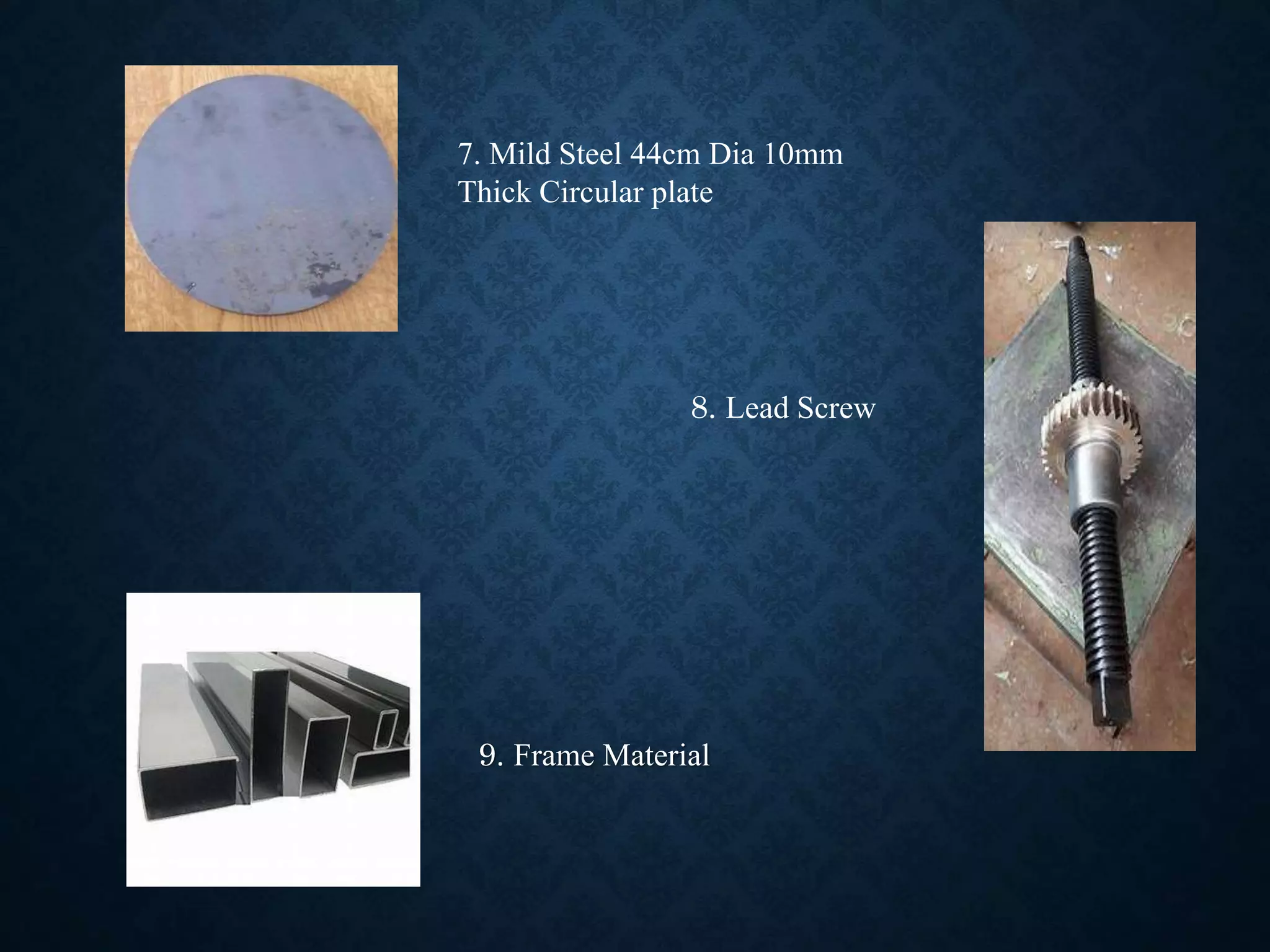

This document describes a final year project to design and fabricate an electronic welding positioner. It presents the problem statement of needing to rotate cylindrical components for uniform welding. The methodology, design, calculations, components, and conclusions are outlined. The positioner uses a motor, gear system, and chain sprocket to rotate the workpiece at 16.66 rpm for welding. The design aims to increase productivity and reduce labor. Future work could include automating the welding gun and controlling the positioner with a microprocessor.