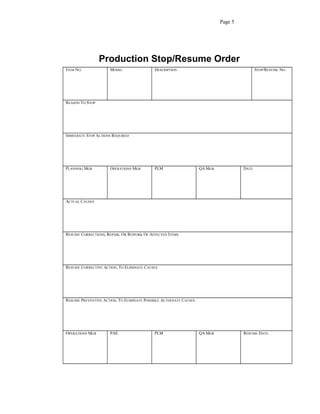

This document outlines a production stop/resume policy and procedure. The policy is intended to prevent defective products from being shipped, provide notice to stop production if defects are discovered, and notify customers of expected delays. The procedure involves initiating a production stop order form when defects are found, distributing notices, and conducting an investigation before receiving management approval to resume production through corrective and preventive actions.