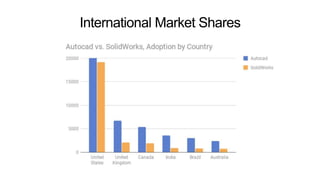

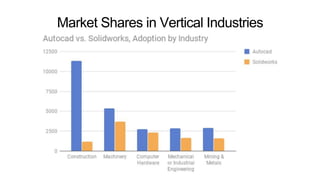

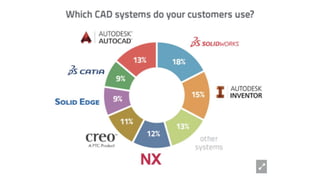

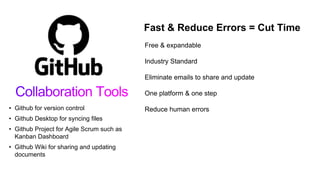

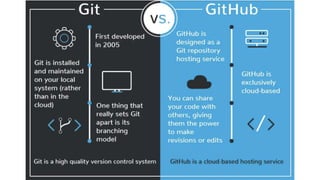

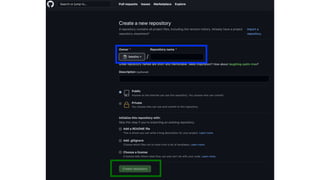

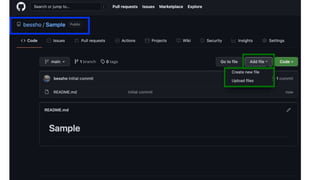

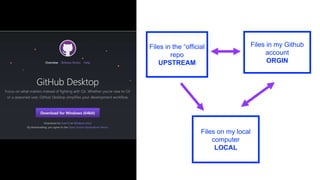

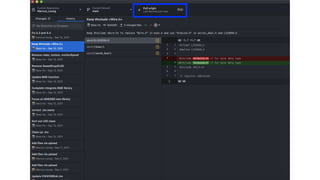

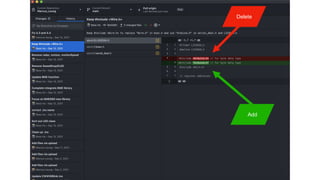

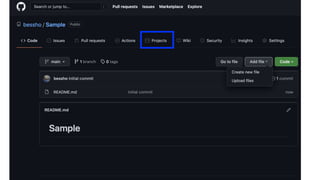

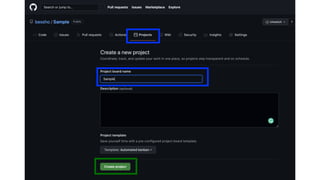

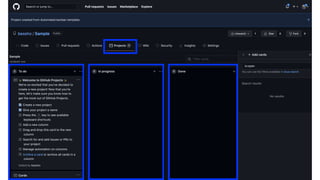

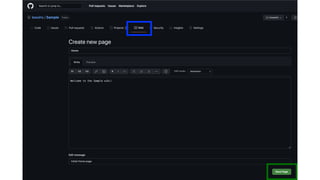

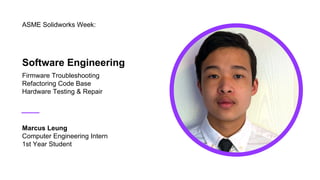

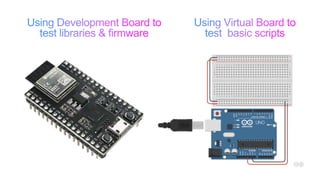

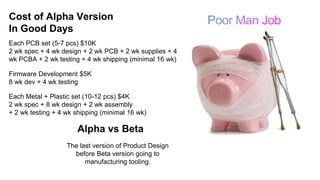

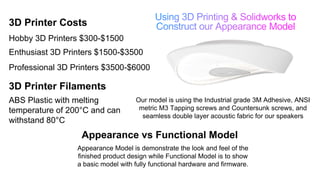

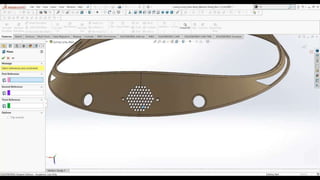

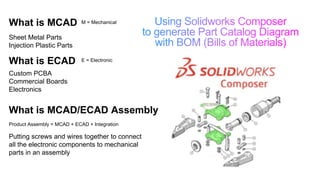

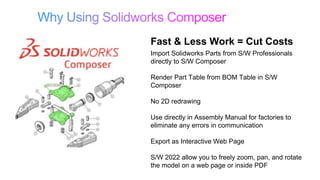

The document summarizes a presentation from the ASME Chapter at UC Irvine on Solidworks and mechanical engineering. It discusses using Solidworks for product design, prototyping, manufacturing, and collaboration. Key topics covered include designing for manufacturability, leveraging 3D modeling to validate designs and cut costs/time, and using platforms like GitHub for version control and project management across multi-disciplinary teams. Advice is given on skills needed for mechanical engineering careers, such as learning CAD software beyond Solidworks and preparing to work with international manufacturers.