This document discusses various aspects of pharmaceutical procurement including:

1. Definitions of key terms like procurement, objectives of procurement, and the six rights of procurement.

2. An overview of the procurement chain and how conflicting objectives can make it challenging.

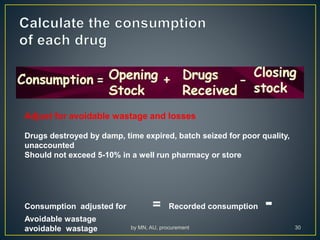

3. Methods for quantifying drug requirements including consumption-based and morbidity-based approaches.

4. Classification tools to analyze and prioritize inventory items like ABC analysis.

5. Techniques for determining optimal order quantities like economic order quantity models.