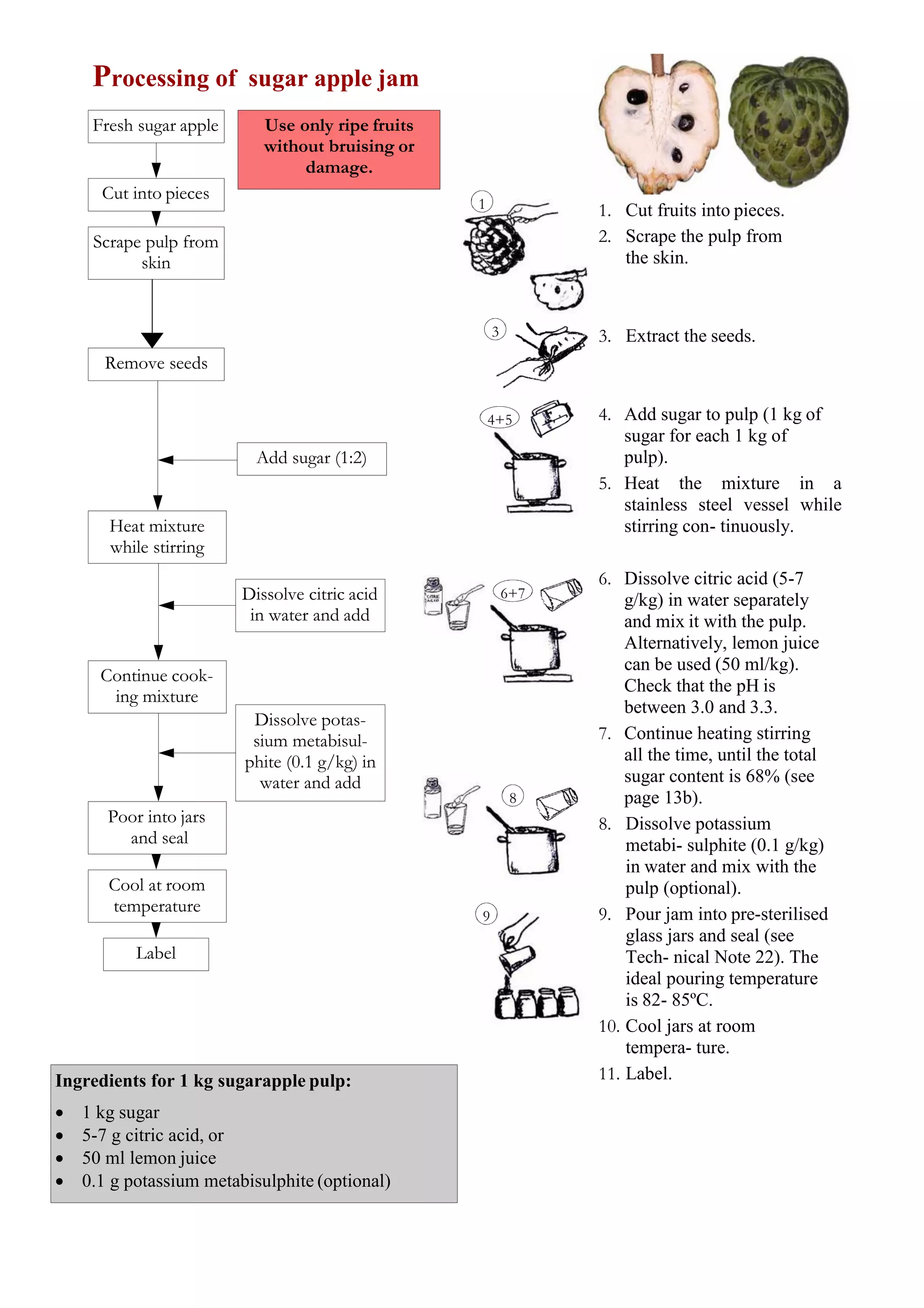

The document provides instructions for processing sugar apple jam. Key steps include:

1) Cutting the fruit into pieces, scraping the pulp, and removing seeds.

2) Adding an equal amount of sugar to the pulp and heating the mixture while stirring continuously.

3) Dissolving citric acid or lemon juice in water and mixing with the pulp to achieve a pH between 3.0-3.3. Continuing to heat and stir until the sugar content reaches 68%.

4) Pouring the hot jam into sterilized jars, sealing, cooling, and labeling the finished product.