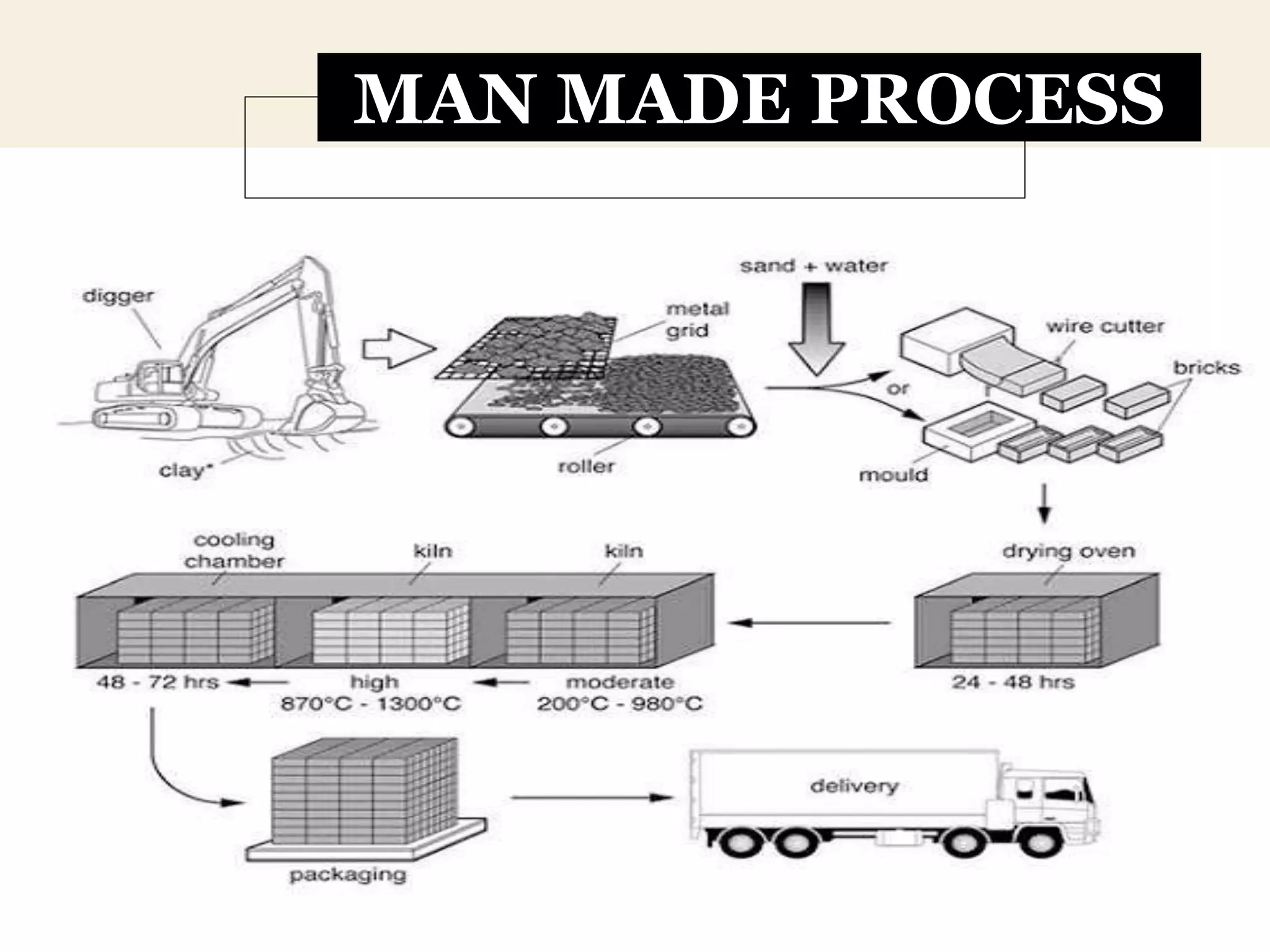

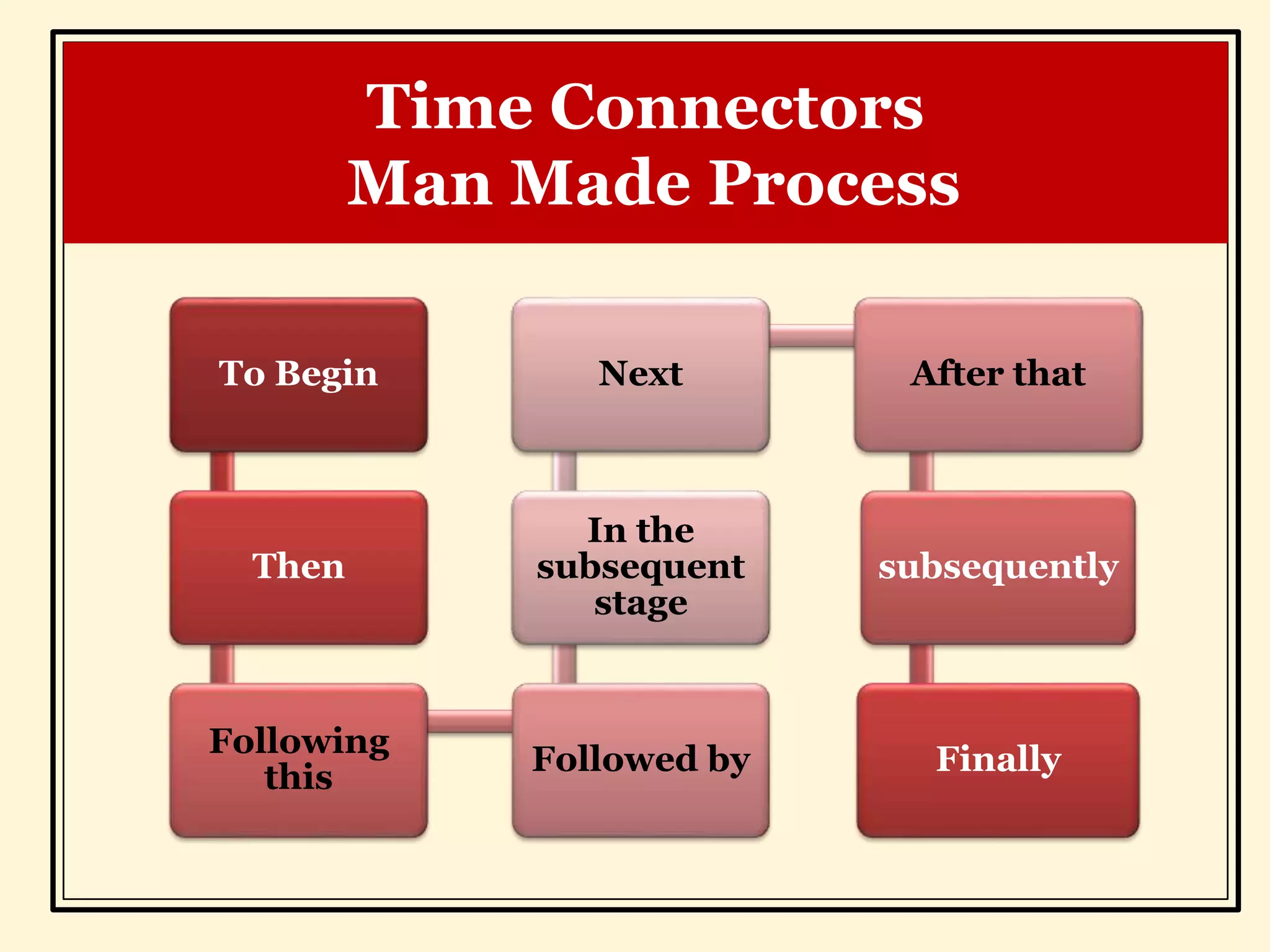

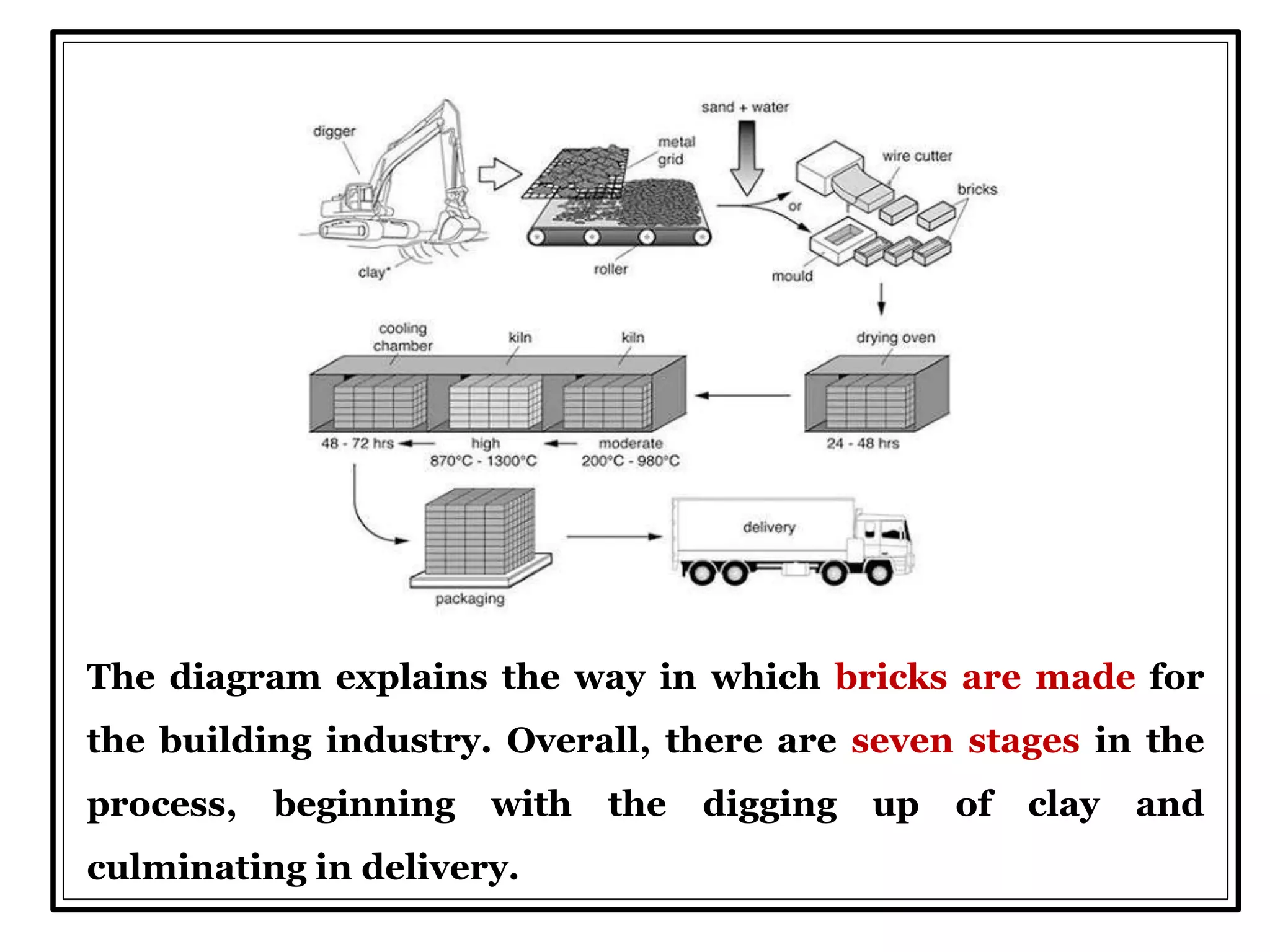

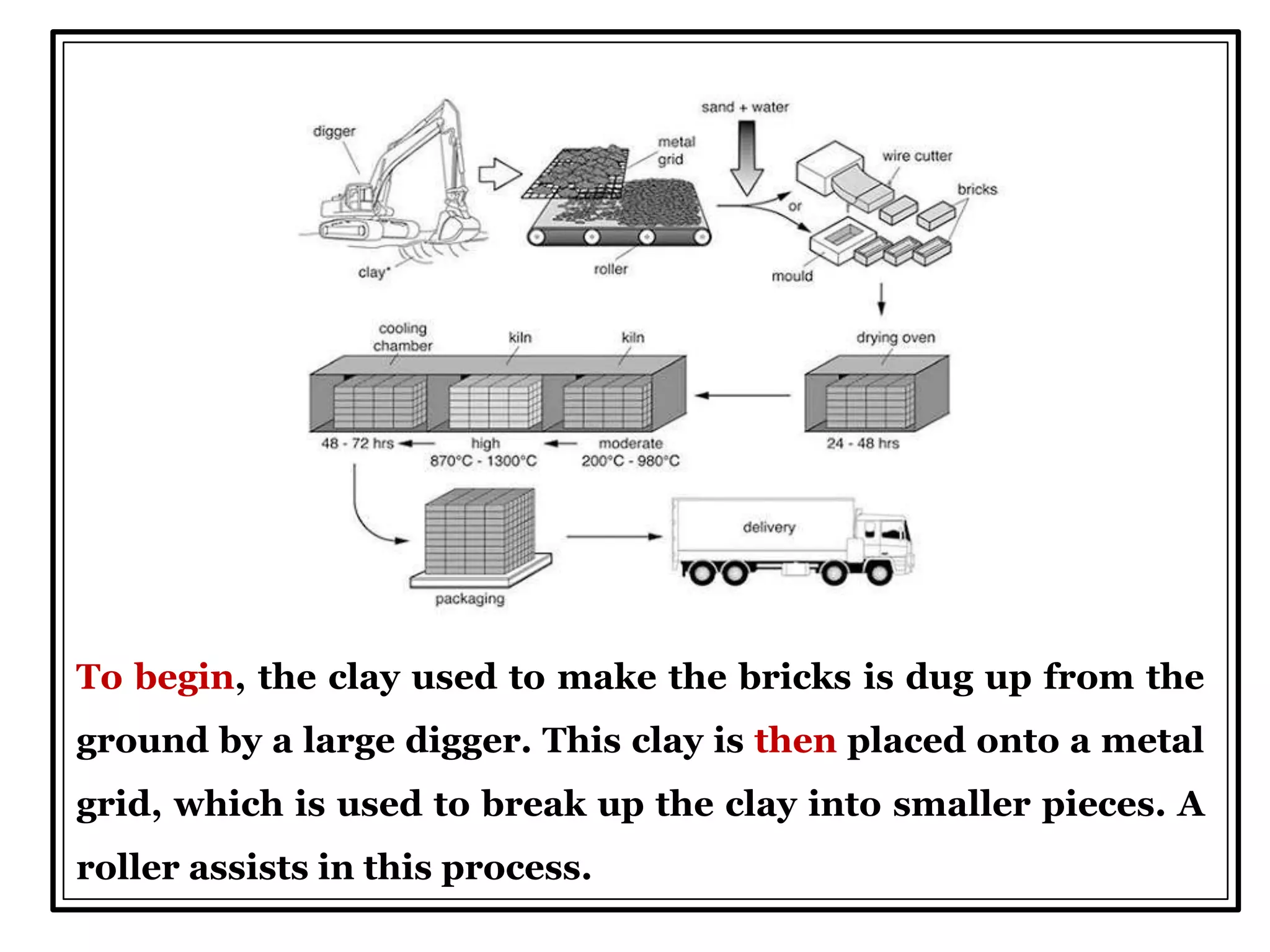

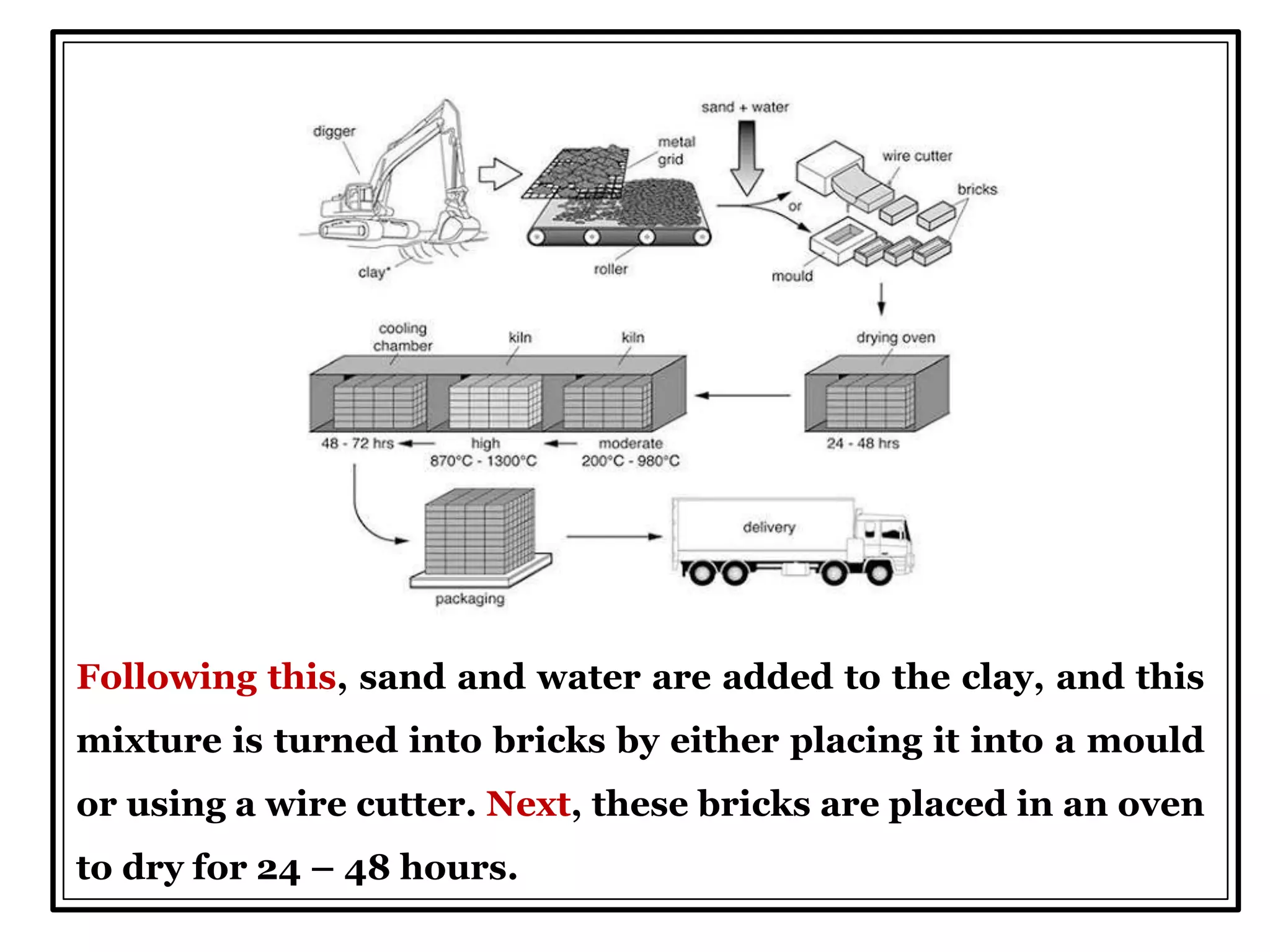

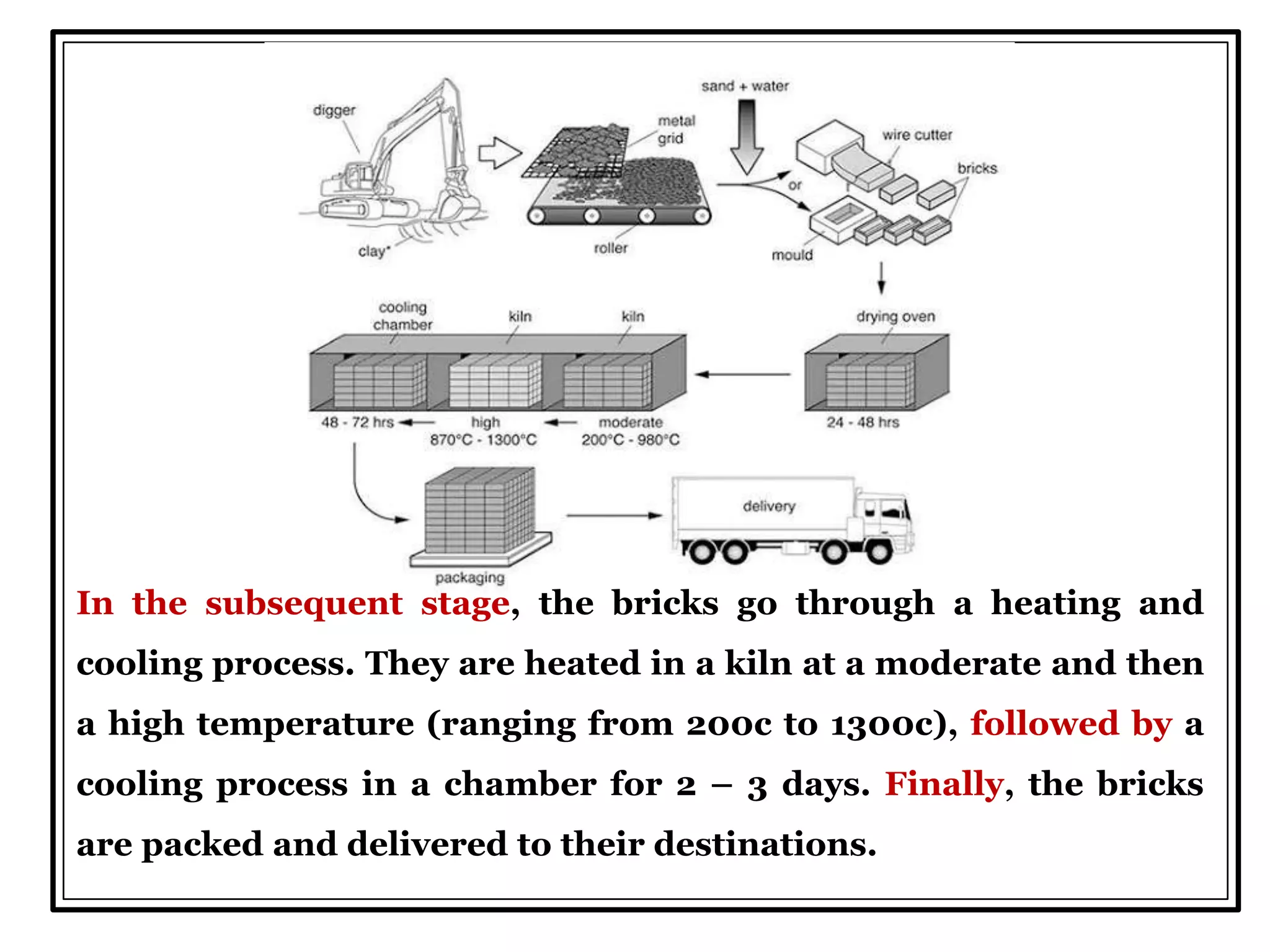

The document describes the process of making bricks for the building industry. There are seven stages: 1) Clay is dug up from the ground by a large digger. 2) The clay is broken into smaller pieces on a metal grid with a roller. 3) Sand and water are added to the clay mixture, which is then formed into bricks by a mould or wire cutter. 4) The bricks are dried in an oven for 24-48 hours. 5) The bricks go through a heating and cooling process in a kiln, being heated to high temperatures then cooled for 2-3 days. 6) Finally, the bricks are packed and delivered.