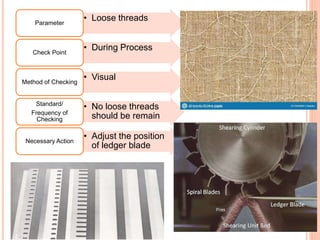

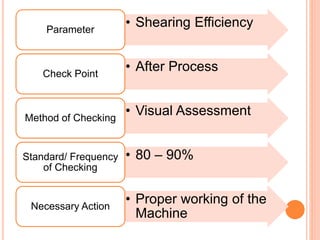

The document outlines quality and process control measures in wet processing, specifically focusing on shearing and cropping machines. Key parameters include checks for metal particles, seams, loose threads, abrasion, long threads, and cut/hole formations, with specified methods of checking and necessary actions for maintenance. The document emphasizes the importance of machine efficiency and overall productivity, recommending regular assessments to ensure optimal operation.