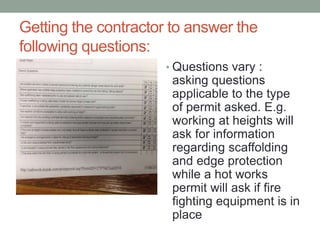

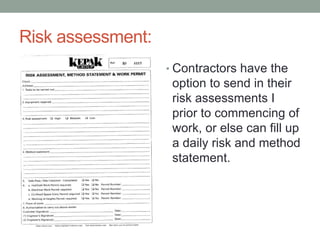

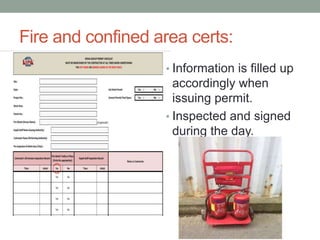

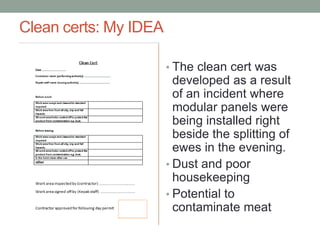

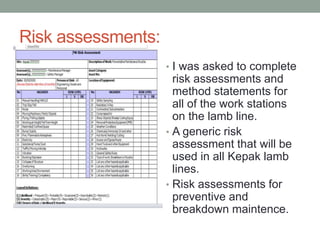

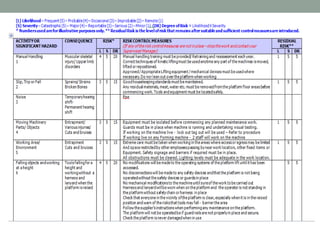

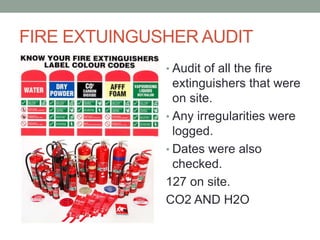

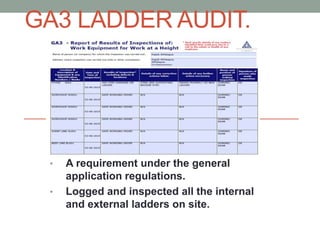

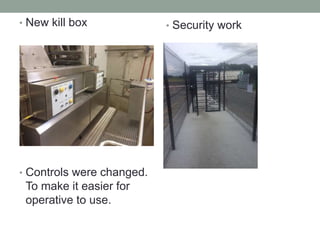

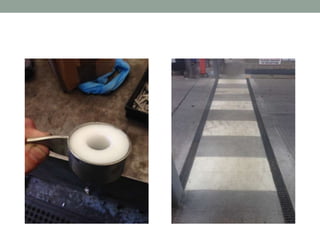

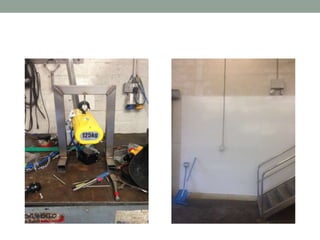

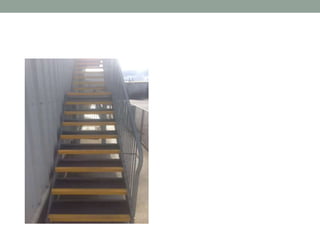

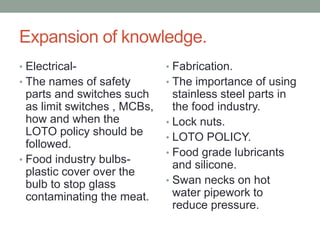

Kepak processes lamb and beef for European and global markets at its Athleague plant. The document discusses health and safety tasks completed during a placement at Kepak, including issuing safety permits, conducting risk assessments, audits of fire extinguishers and ladders, tool box talks, and general operative interviews. It also outlines various maintenance and construction projects overseen at the plant involving contractors, such as renovating toilets, installing a new pan line and sterilizer, changing controls on the kill box, improving drainage, and expanding refrigeration units.