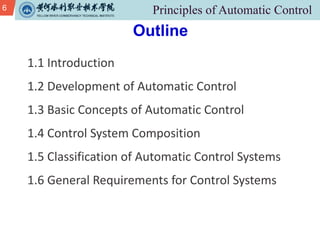

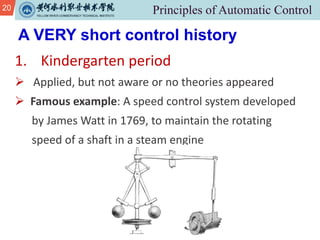

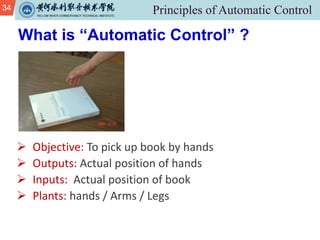

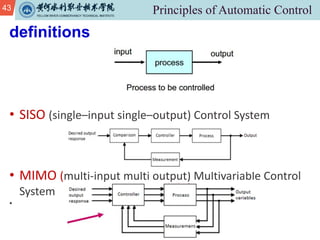

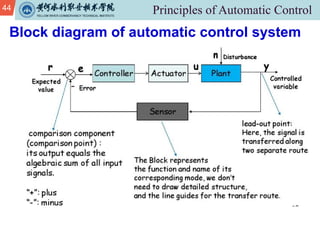

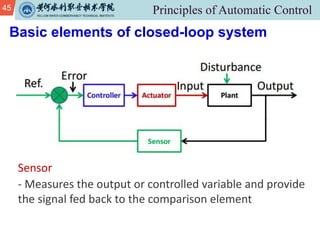

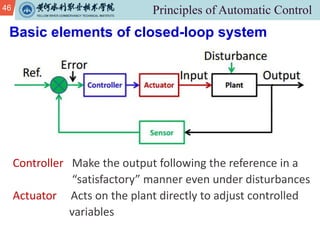

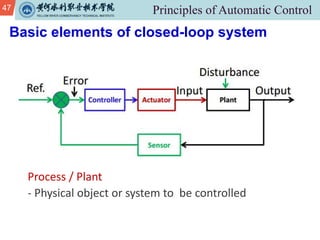

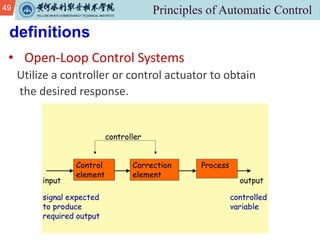

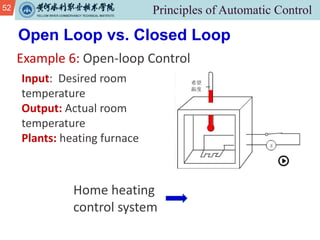

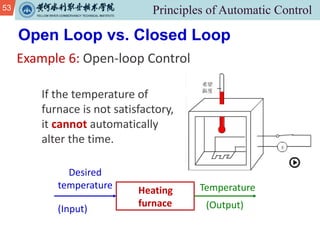

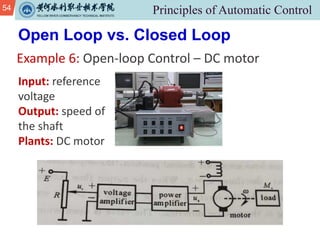

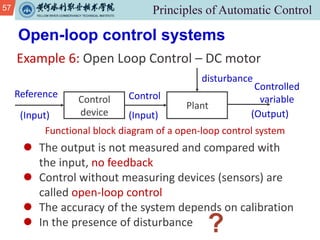

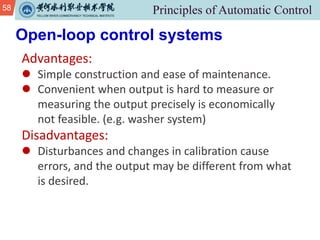

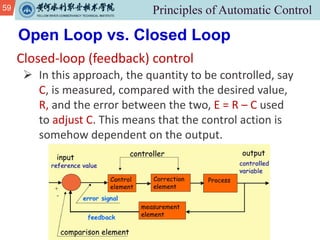

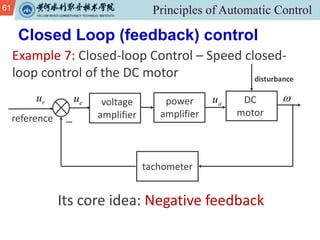

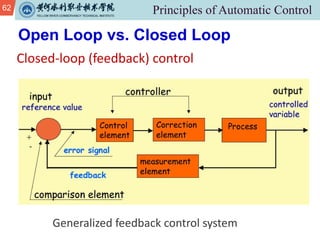

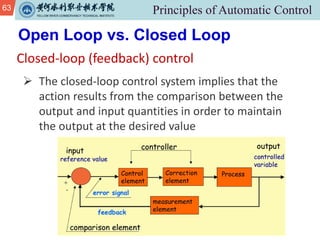

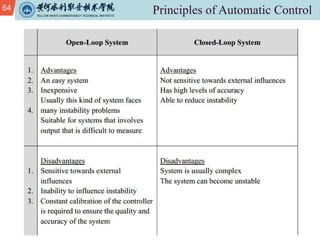

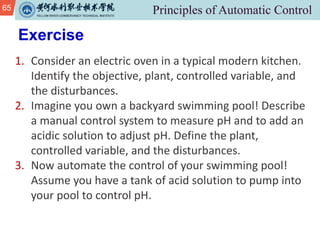

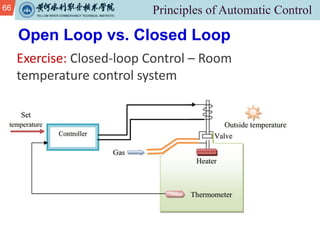

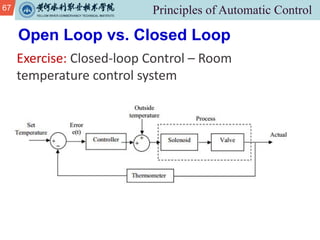

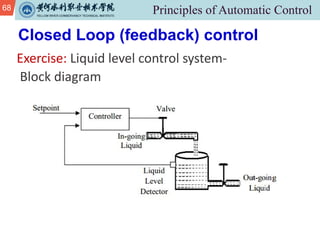

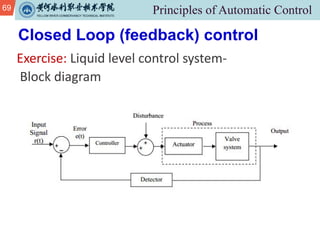

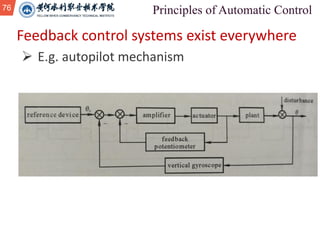

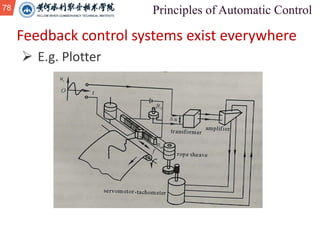

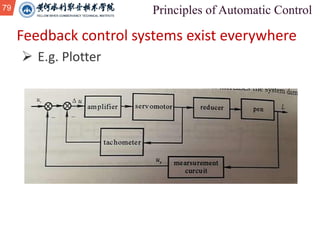

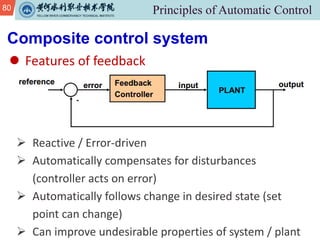

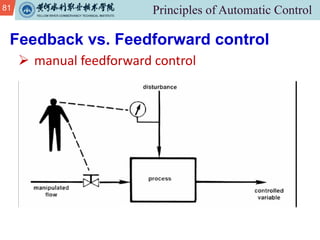

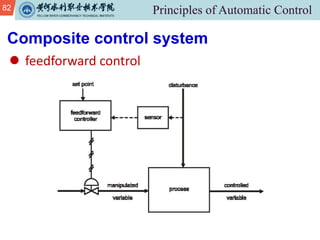

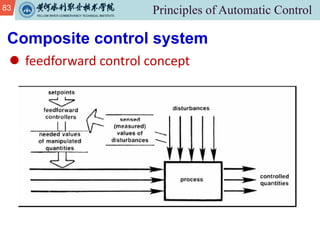

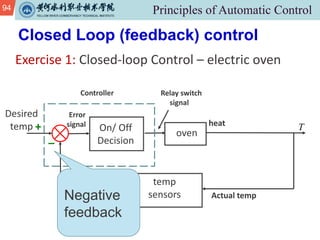

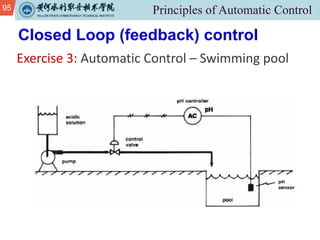

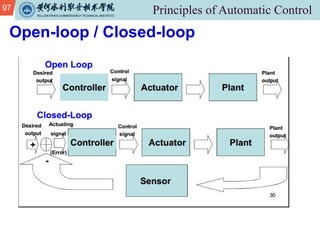

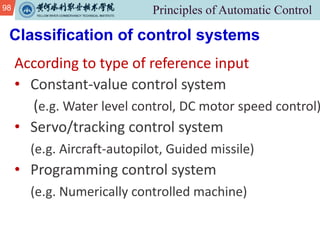

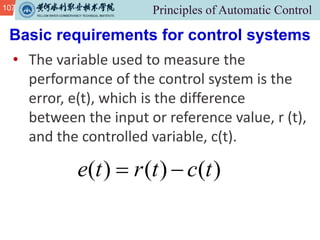

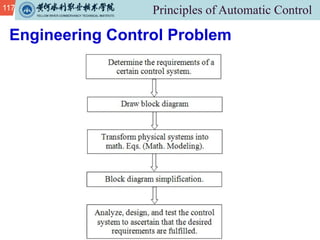

This document provides an overview of a course on principles of automatic control. It introduces the instructor Qingpu Hu and provides details on lectures, grading, objectives, course materials, and the course outline. The course will cover basic concepts of control systems including open-loop and closed-loop control, feedback control, block diagrams, and components of control systems. It will help students develop a basic understanding of control systems and their engineering applications.