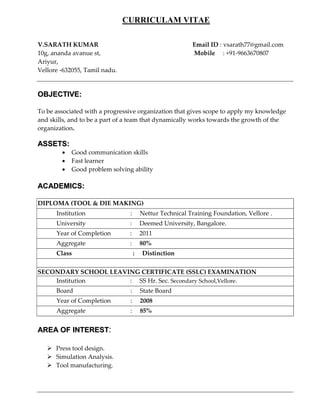

V. Sarath Kumar is seeking a position that allows him to apply his skills and knowledge to help an organization grow. He has over 6 years of experience in tool design and manufacturing. He has a diploma in Tool and Die Making and is proficient in CAD software like AutoCAD, Pro-E, and ESI-Pam Stamp. Currently he works as a senior tool design engineer where he leads a design team and has experience designing various press tools, performing simulations, and coordinating with different departments. He has experience working on projects for companies like TVS, Magna, and Lear Corporation.