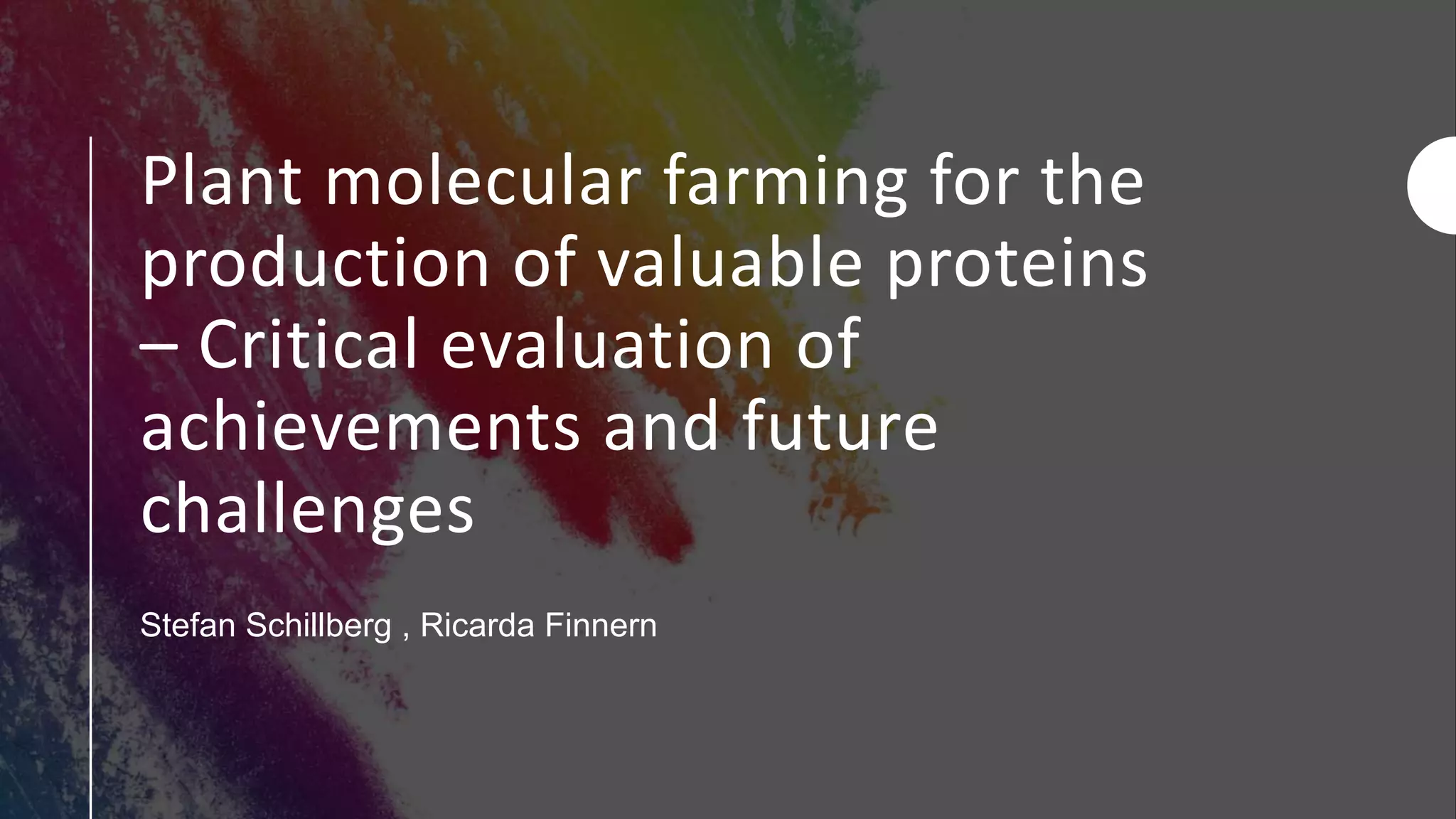

This document discusses the production of valuable proteins through plant molecular farming. It begins by introducing molecular farming as an alternative to microbial and mammalian expression systems. Several early successes in the 1980s demonstrated that plants could produce complex mammalian proteins like antibodies. However, downstream processing challenges have limited the number of commercial successes. The document examines the technical and economic factors needed for successful commercialization, including optimizing platforms like tobacco for productivity and processing. Plant systems offer diverse options for protein expression but must be systematically compared. Clinical trials show plants can produce vaccines, antibodies, and replacement human proteins. Overall production consistency and downstream processing remain challenges for the broader application of plant-based protein production.