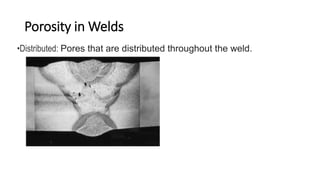

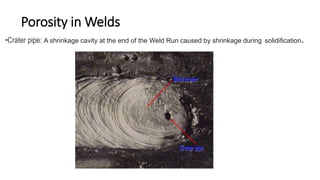

Porosity in welds refers to gas pockets that form in welded metal. Porosity can take different forms such as being distributed throughout the weld, breaking the surface, or appearing as elongated pores in a herringbone pattern. Various testing devices like x-rays are used to detect porosity that may not be visible to the naked eye. Steps to prevent porosity include removing contaminants from the welding surface, avoiding joint geometries that cause cavities, progressively reducing welding current, and sealing air leaks.