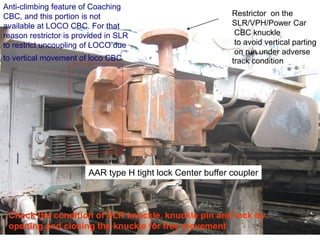

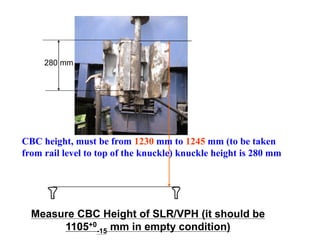

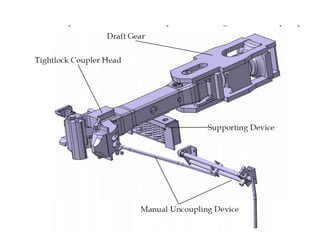

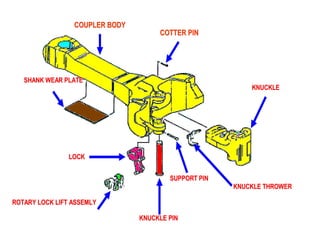

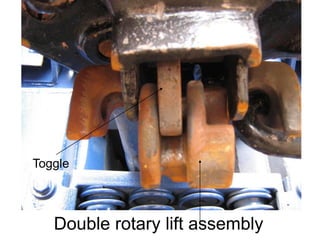

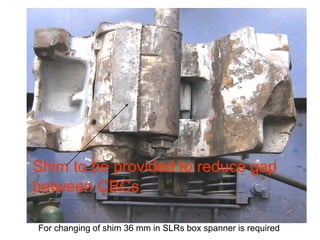

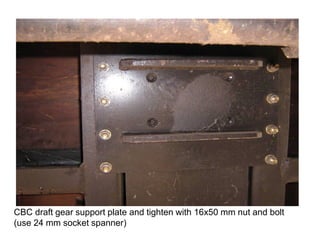

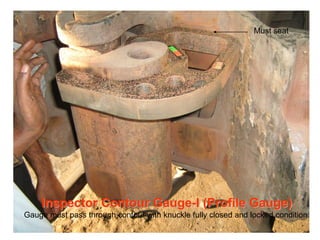

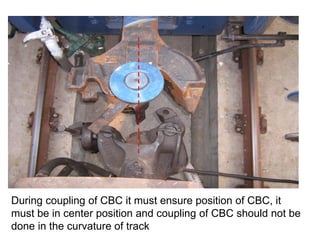

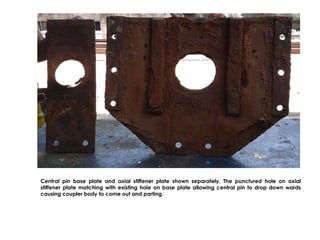

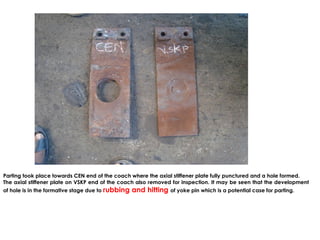

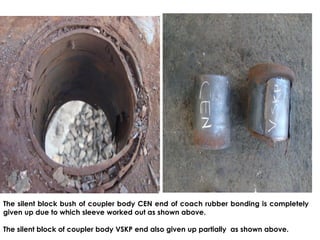

The document discusses the maintenance and inspection procedures for AAR Type H Tight Lock Center Buffer Couplers in coaching vehicles, emphasizing the importance of proper component checks and adjustments to ensure safety and functionality. It outlines specific measurements, tools required, and common pitfalls to avoid during maintenance, such as not applying grease to critical locking mechanisms. The report highlights a case of potential failure in a coupler due to wear and structural damage, underscoring the need for rigorous routine inspections.