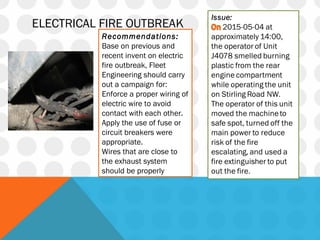

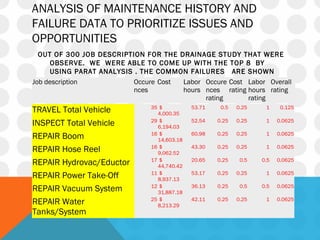

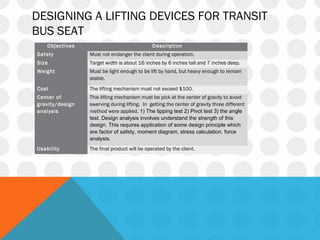

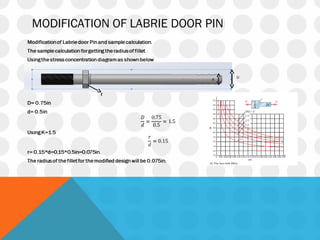

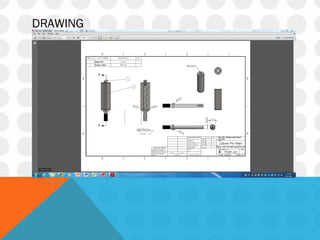

This document summarizes the experiences and projects of a 4-month co-op with the Fleet Engineering Department of the City of Edmonton. It describes several projects completed including analyzing maintenance data for drainage trucks, designing a lifting device for transit bus seats, investigating an electrical fire in a sweeper truck, and modifying Labrie door pins. The co-op provided opportunities to apply academic knowledge to real-world situations while working with other professional engineers in more of a family setting. Diagrams and drawings are included to illustrate some of the projects.