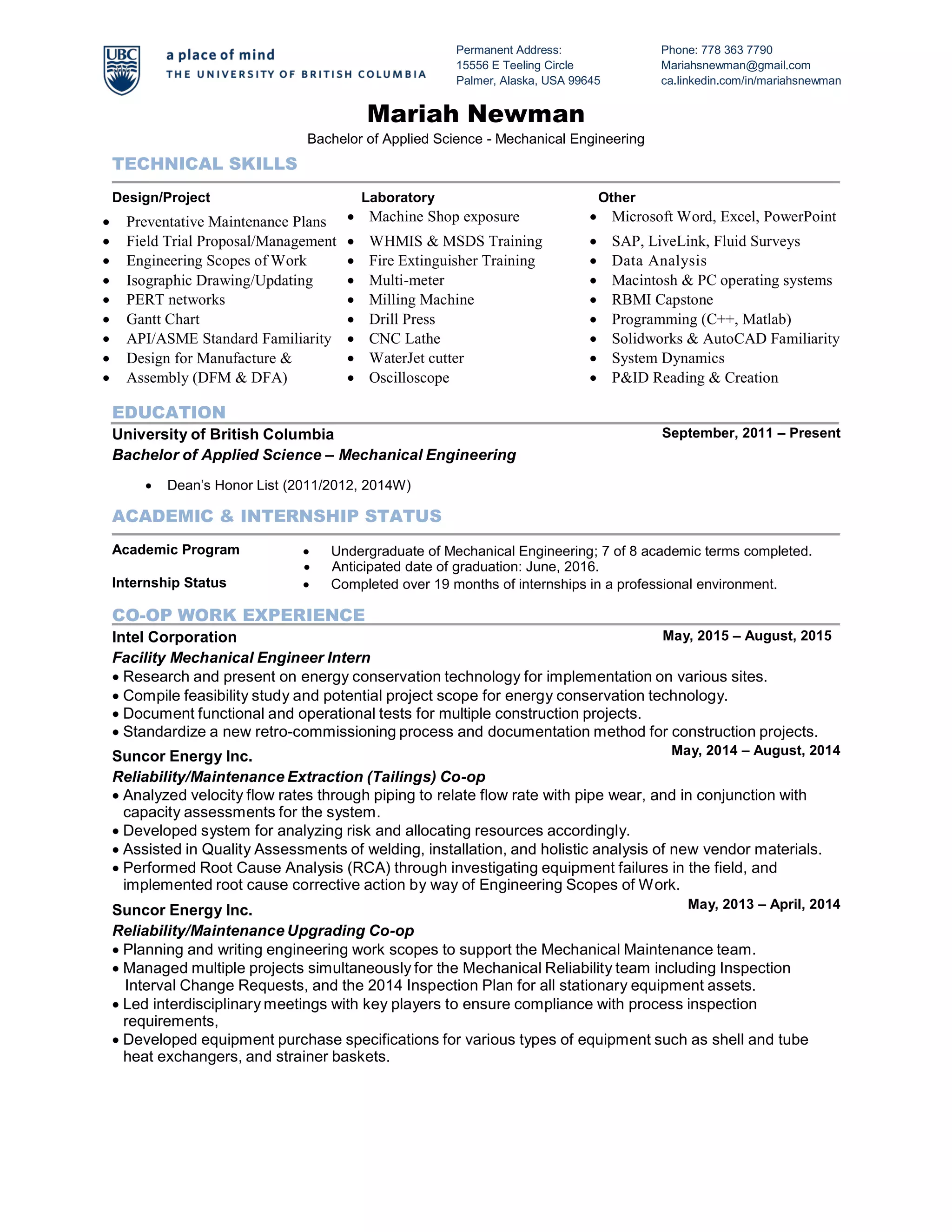

This document contains contact and background information for Mariah Newman, including her education, skills, work experience, and projects. She has a Bachelor of Applied Science in Mechanical Engineering from the University of British Columbia. Her relevant work experience includes internships at Intel and Suncor Energy in facilities engineering and maintenance roles. She is currently working on her capstone design project involving the design of a robotic climber.