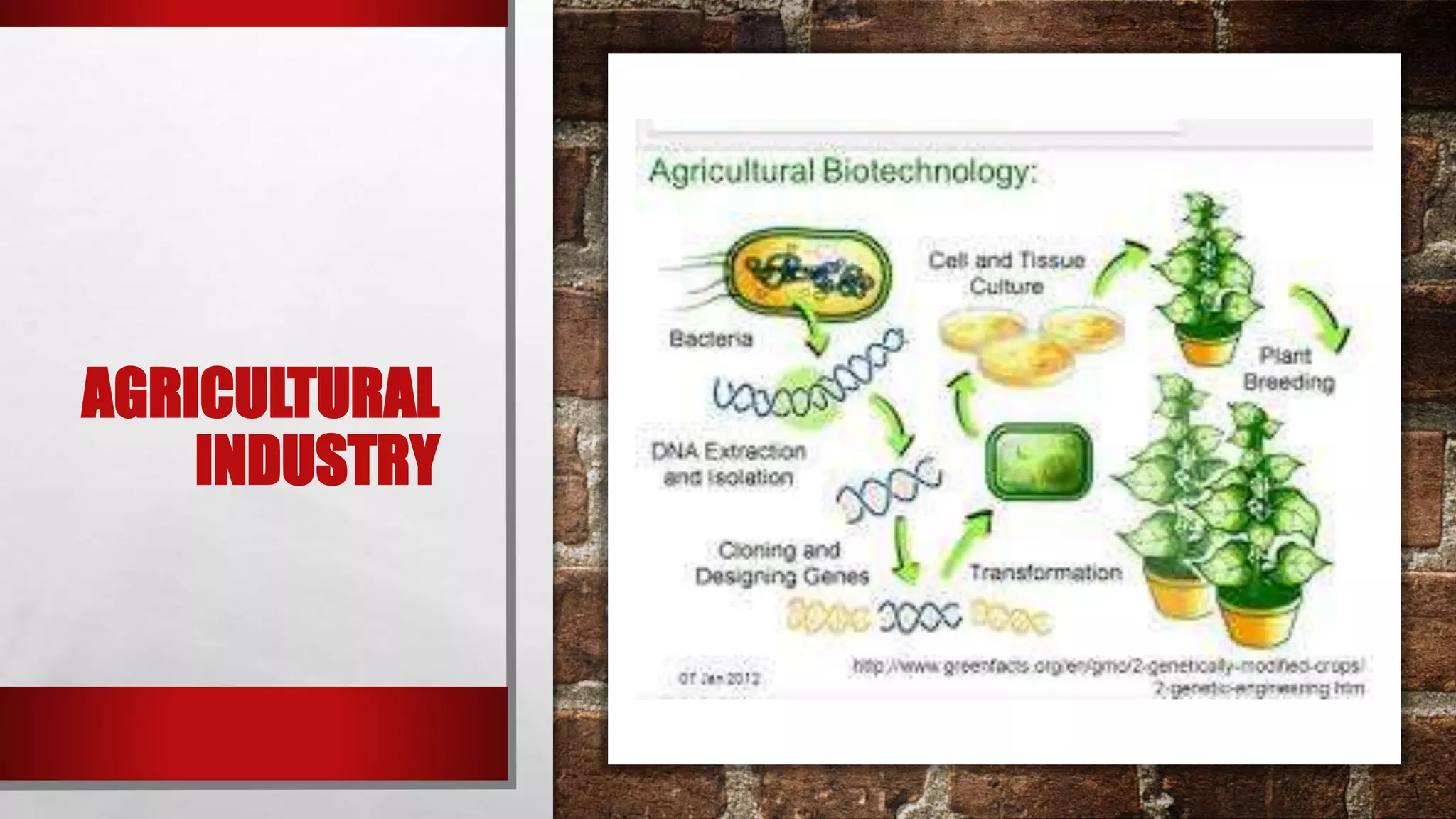

This document provides an overview of biotechnology in Pakistan across several industries. It discusses how biotechnology is used in the pharmaceutical, chemical, food and agriculture, and textile industries in Pakistan. Enzymes and microorganisms are used in industrial bioprocessing. The pharmaceutical industry utilizes biotechnology for vaccine and antibiotic production. The chemical industry uses biotechnology for citric acid and lactic acid production. Biotechnology enhances crop breeding and development of BT cotton in the agriculture industry. It also improves textile fiber quality and processing.