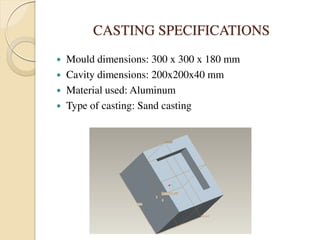

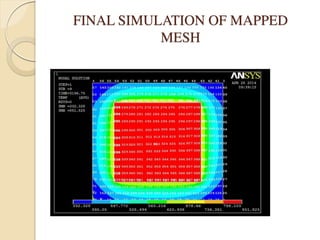

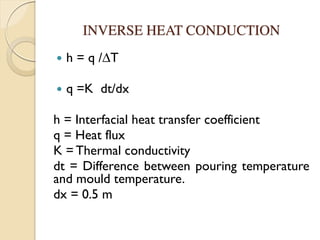

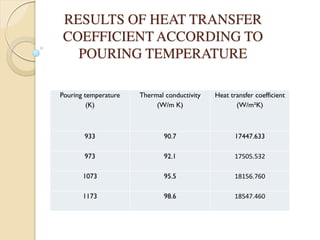

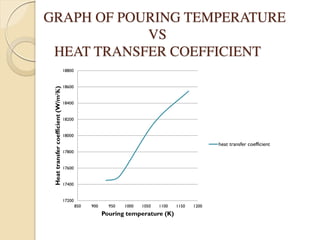

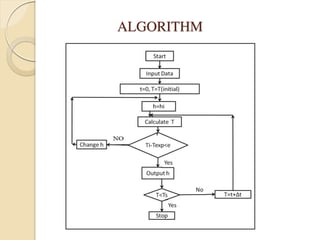

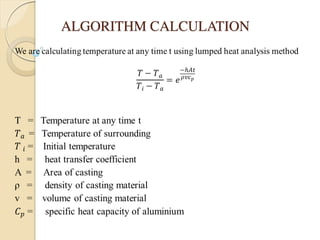

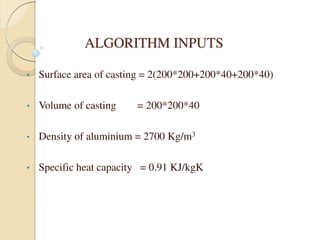

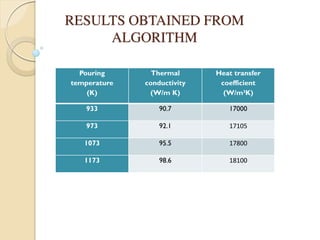

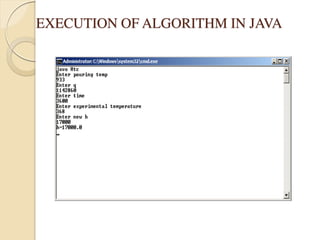

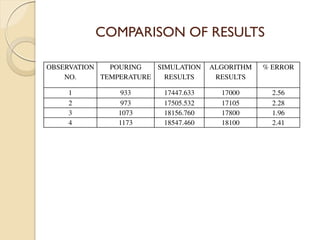

This document describes the development of an algorithm to calculate the interfacial heat transfer coefficient (IFHTC) for a sand casting process. The algorithm is developed through ANSYS simulations of heat transfer during casting of an aluminum plate. Two meshing techniques, free mesh and mapped mesh, are used. The inverse heat conduction method is applied to calculate IFHTC from heat flux and temperature difference data. IFHTC is calculated for different pouring temperatures and an algorithm is developed and coded in Java. Results from the algorithm match well with ANSYS simulations, with less than 2.5% error. Future work may involve extending the algorithm to other materials, shapes, and optimizing additional casting parameters.